Unmatched Inspection Accuracy.

White-Glove Support.

Overview's AI vision systems deliver state-of-the-art accuracy, with industry leading ease-of-use and maintainability

Trusted by Top Manufacturers

Powering quality control at leading manufacturers worldwide

Transform Your Manufacturing Operations

See how Overview's AI vision platform makes your quality control more accurate and your implementation faster.

Use Cases

Real-world inspection scenarios our AI solves

Assembly Verification

Ensure precise part placement and alignment — even for small components.

Defect Detection

Instantly identify cracks, porosity, and missing welds on varied surfaces.

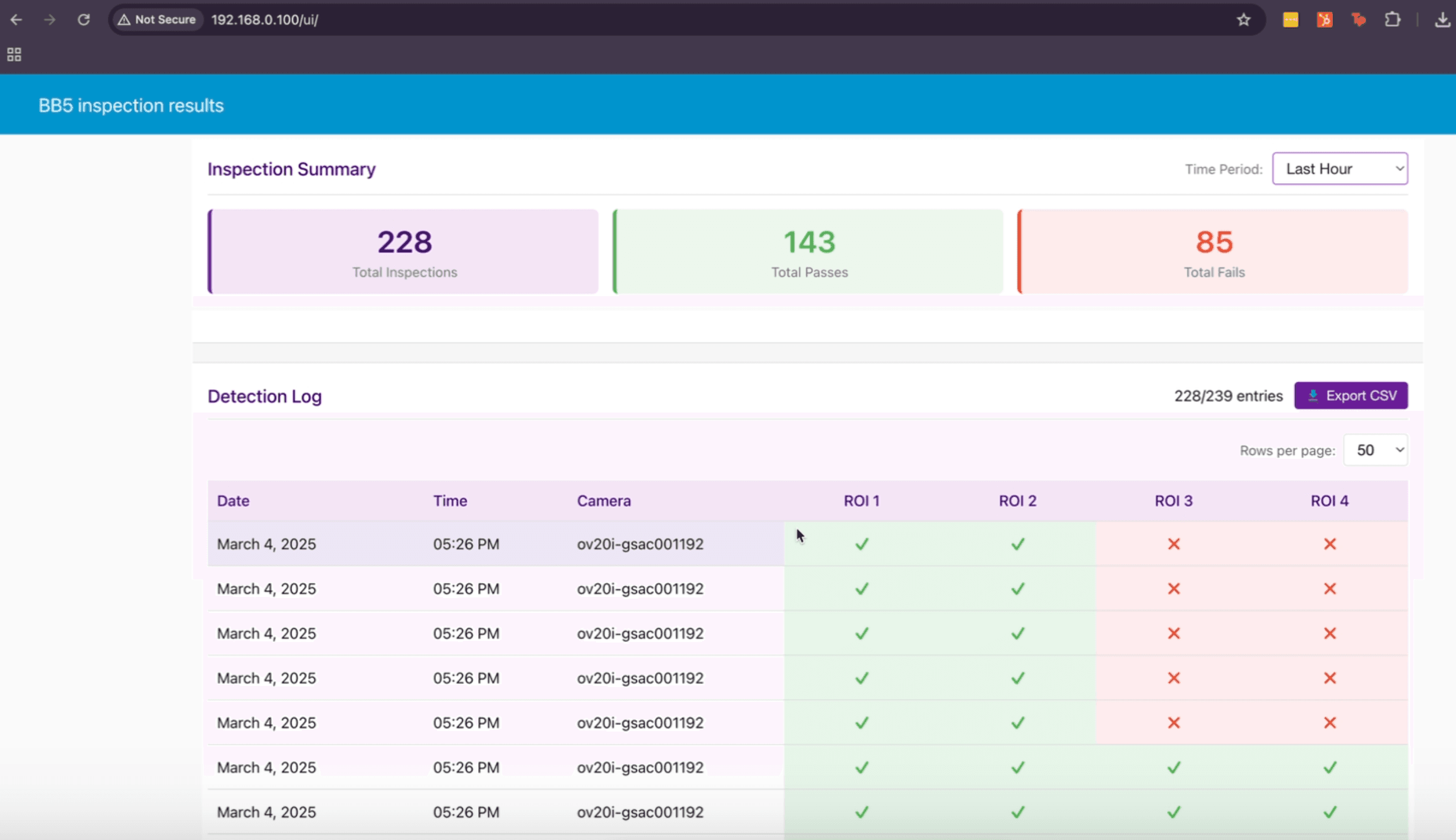

Multi-point Inspection

Verify multiple critical checkpoints in one scan for efficient QA.

Interoperable and customizable to your factory

Proven on Your Toughest Applications

From micro-defects to fast-moving production lines with variable conditions—deep learning vision adapts where rule-based systems fail.

Fast Implementation, Faster Payback

Deploy production systems in hours. Train models in minutes. Achieve ROI in weeks—not quarters.

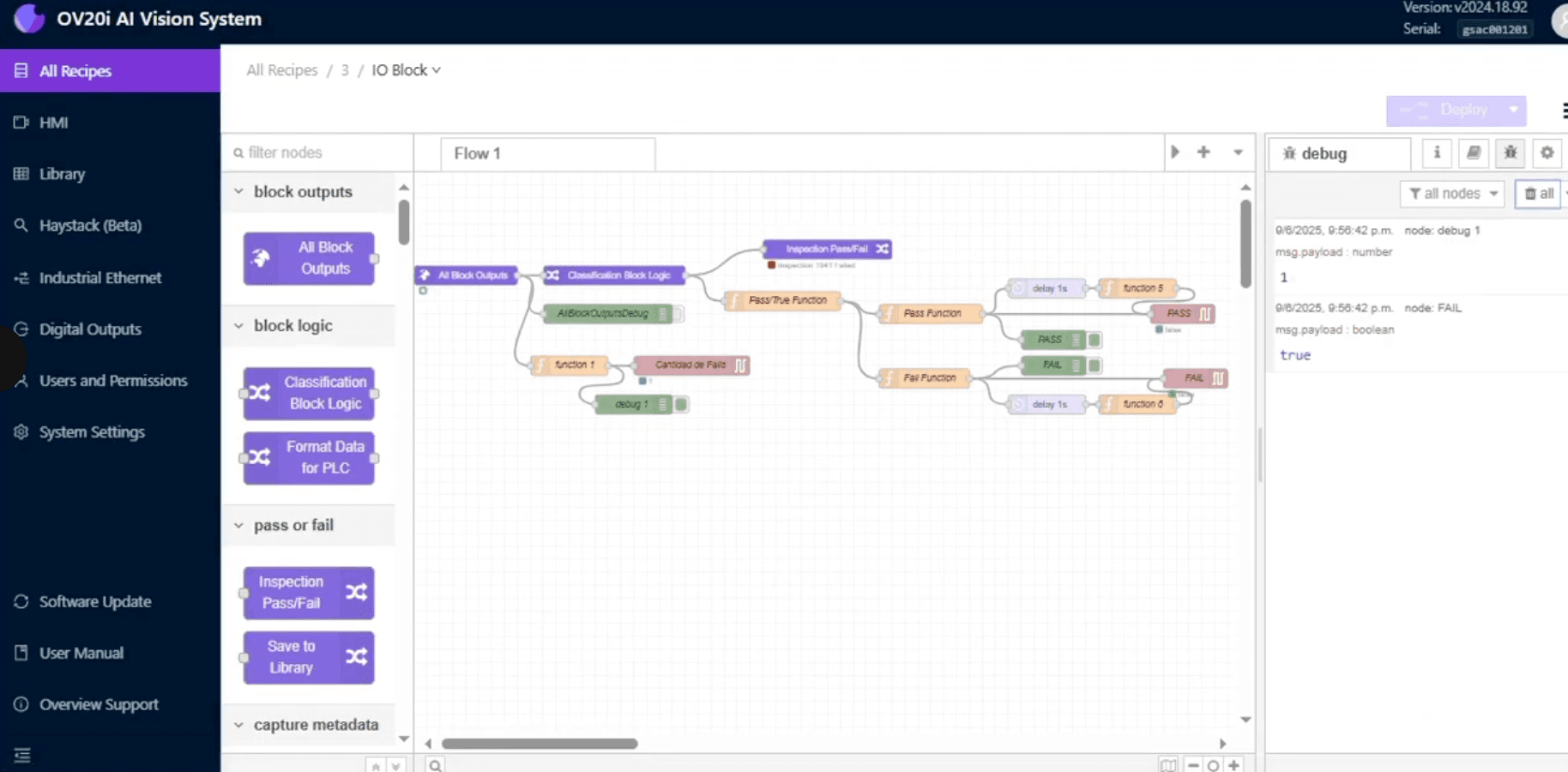

Your System, Your Control

Edge computing runs deep learning inference directly on camera hardware—real-time processing, complete data sovereignty, zero vendor dependency.

Built for Your Team to Run

Manufacturing engineers configure systems. Operators execute inspections. No computer vision specialists required.

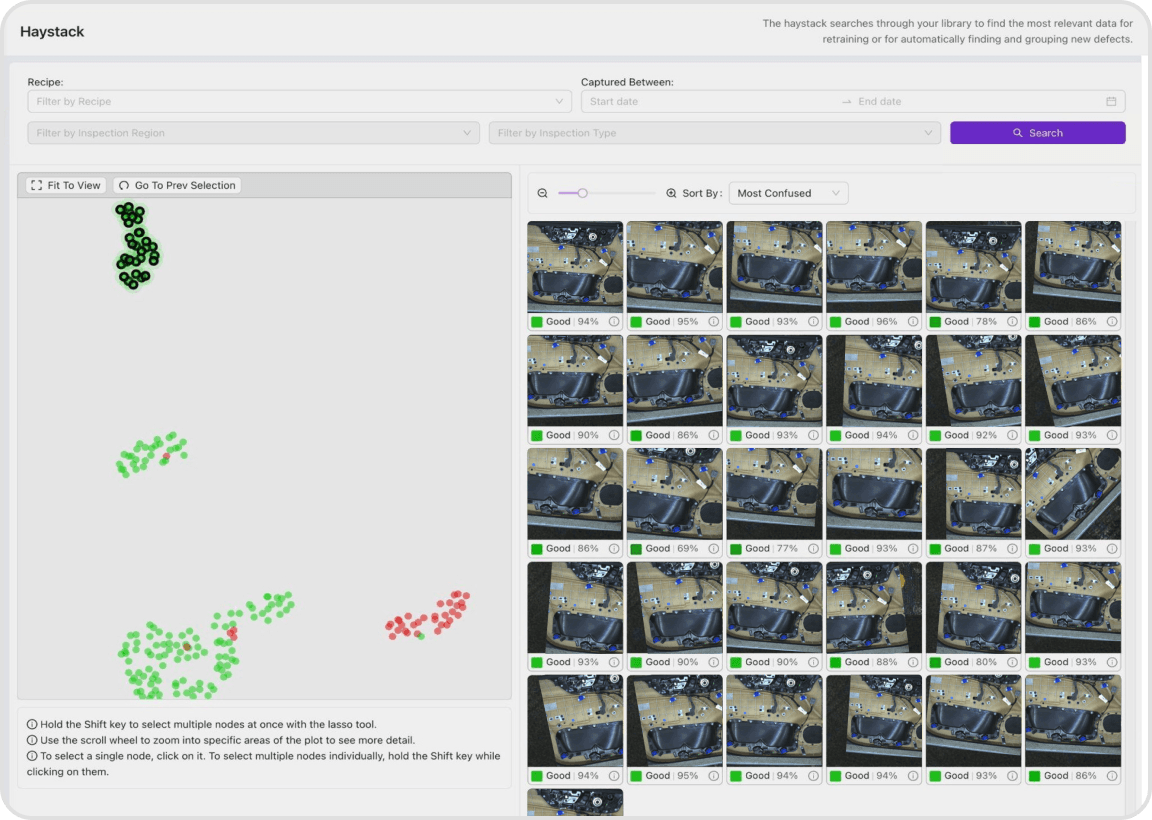

Adapts As Your Production Evolves

Haystack visualization exposes model uncertainty. Teams retrain and adapt models in minutes—no vendor dependency for continuous improvement.

Your Success Partner, Not Just a Vendor

Our team identifies high-value inspection points and ensures production-grade performance from day one.

What Our Customers Say

Trusted by leading manufacturers worldwide for mission-critical quality inspection

“I am going to use this camera instead of our in-house vision system.”

Senior Vision Engineer

Automotive OEM

Ready to Transform Your Production?

Join manufacturers worldwide using Overview AI vision systems

Schedule a Demo