Fire Extinguisher Visual Inspection: Automating NFPA/OSHA Compliance with AI Vision

Manual fire extinguisher checks are labor-intensive, inconsistent, and hard to audit across large facilities. AI-powered machine vision systems automate visual inspection—reading pressure gauges, verifying tamper seals and pins, checking labels and service dates, and confirming placement—so EHS and operations teams stay compliant with NFPA 10 and OSHA 1910.157 at scale.

The Problem: Manual Visual Checks Don’t Scale or Hold Up in Audits

Monthly visual inspections are required by OSHA 1910.157 and NFPA 10, with annual maintenance, periodic internal examinations, and hydrostatic testing (intervals vary by cylinder type). In practice, traditional clipboard checks and ad hoc mobile apps fail under production realities.

Where manual inspection breaks down:

- Inconsistent execution: Gauge needles, hairline cracks, minor dents, and nozzle obstructions are easy to miss—especially across hundreds or thousands of units.

- Documentation burden: Inspectors must verify placement, accessibility, correct class/size, pressure, pin and seal integrity, hose/nozzle condition, brackets, labels, service tags, and hydro dates—then record it all accurately. Errors compound at multi-site scale.

- Misreads and bias: Small fonts on tags, faded labels, and dirty gauges drive misinterpretation; “green zone” reads are subjective in poor lighting or at distance.

- Coverage gaps: Relocated equipment, blocked access, or missing units go unnoticed between rounds. Route compliance is hard to prove without time-stamped evidence.

- Reactive maintenance: Without structured defect data, teams discover issues during audits or incidents—triggering rework, fines, or worse.

- Assembly quality risk: For manufacturers and service centers, verifying pin/seal presence, label correctness, pressure, and hose/nozzle assembly is repetitive and error-prone, leading to costly rework and field failures.

The result: inconsistent compliance, increased risk, and audit friction. Even with strong training, humans alone can’t deliver the repeatability and objective records regulators and insurers expect.

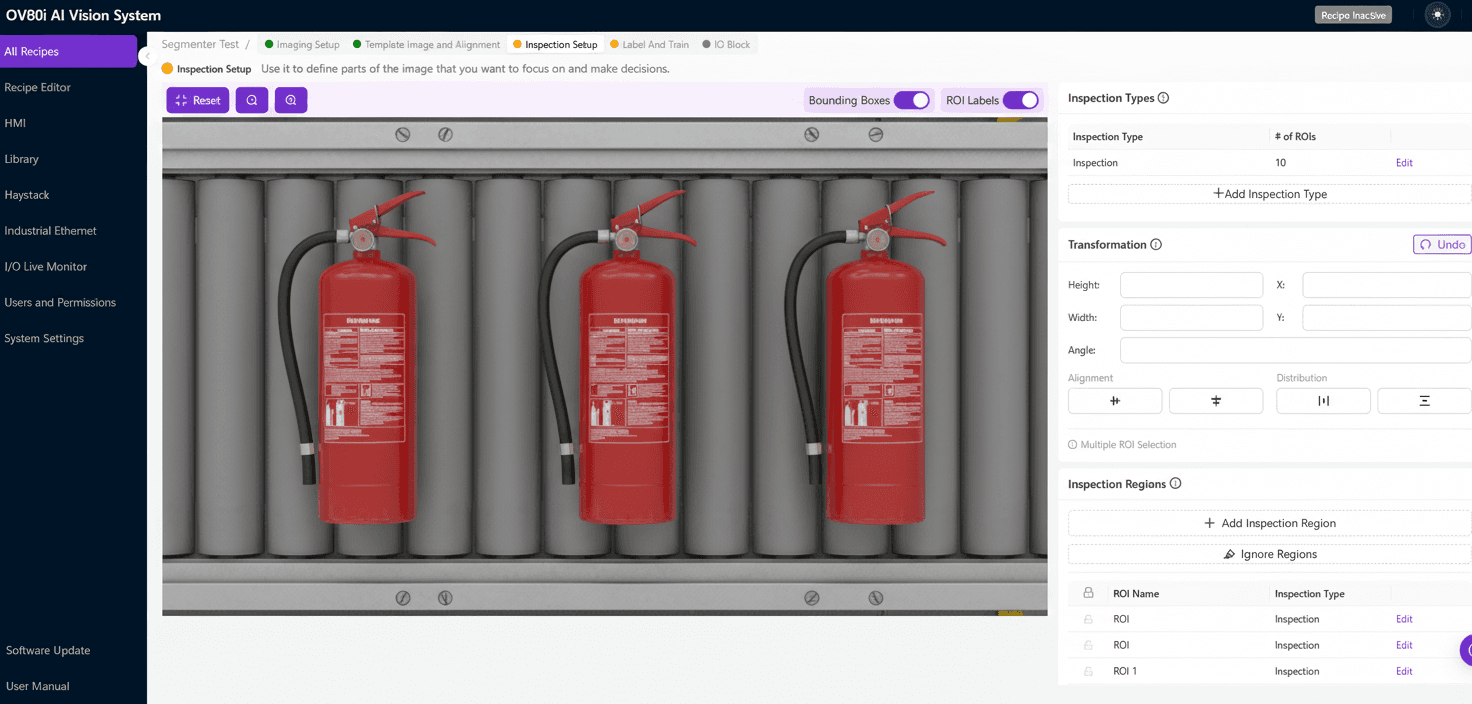

The Solution: AI Computer Vision that Makes Visual Inspection Objective, Fast, and Audit-Ready

Modern vision inspection systems combine high-resolution imaging, domain-tuned AI models, and workflow integrations to turn fire extinguisher inspection into a reliable, closed-loop process. Deployed as fixed cameras at manufacturing/service stations or as mobile-assisted inspection on the plant floor, machine vision systems provide automated visual inspection with consistent outcomes and instant documentation.

What AI vision detects and verifies:

- Pressure and charge status

- Reads analog pressure gauges; confirms needle within “green” band.

- Detects missing or damaged gauges.

- Safety hardware integrity

- Pull pin presence, orientation, and fit.

- Tamper seal intactness and correct routing.

- Bracket integrity and secure mounting.

- Condition and damage

- Dents, corrosion, paint loss, rust streaks, cracks, abrasion on hoses.

- Nozzle obstructions, caps present where required.

- Labeling and suitability

- OCR on classification (ABC, CO2, Class K), capacity, serial numbers, and manufacturer/service labels.

- Confirms the extinguisher type matches zone requirements.

- Checks label legibility and completeness.

- Service status and compliance dates

- OCR of inspection tags for last monthly/annual check.

- Reads hydrostatic test and internal examination dates; flags when due.

- Verifies recharge indicators post-discharge/maintenance.

- Placement and accessibility

- Confirms height and clear floor radius via depth/geometry.

- Detects obstructions (pallets, carts, stacked materials) in front of cabinets/stands.

- Validates presence and visibility of signage where required.

How it works in practice:

- Capture: A fixed or mobile camera captures images/video in consistent lighting. No special stickers needed; system learns from real-world variance.

- Analyze: AI models perform detection, segmentation, and OCR; rule sets encode NFPA/OSHA criteria and site-specific standards.

- Decide: The system returns pass/fail with reasons and severity, guiding the technician to remediate or escalate (e.g., remove from service).

- Record: All results are time-stamped with images, readings, and geolocation. Digital records map each unit to its ID/serial for a complete history.

- Integrate: Events sync to EAM/CMMS (work orders), MES/ERP (for manufacturing assembly verification), and safety dashboards for trend analysis and audit exports.

Engineering-grade reliability:

- Repeatability: Calibrated imaging and model thresholds eliminate subjective reads.

- MSA-ready: Systems can be validated with Gage R&R to quantify detection capability before rollout.

- Secure and scalable: On-edge processing for speed and privacy; cloud aggregation for enterprise reporting.

AI vision doesn’t replace certified technicians for annual maintenance or hydrostatic testing; it ensures monthly visual inspection is systematic, objective, and fully documented while triaging units that require professional service.

Key Applications & Outcomes

Where to Deploy

- Manufacturing assembly verification: End-of-line checks confirm correct valve assembly, pin/seal, gauge, hose/nozzle, labeling, and finish quality before packing. Automated visual inspection reduces escapes and rework, and maintains brand reputation.

- Service and recharge centers: Vision inspection system verifies post-service reassembly, correct recharge status, date stamps, and tag updates before return to the customer.

- Facility monthly visual inspections: Mobile AI guidance accelerates rounds, ensures complete coverage, and captures visual proof for every unit.

- Receiving and logistics: Automatically screen incoming extinguishers for damage and correct type allocation to zones.

- High-risk areas (kitchens, labs, battery rooms): Continuous or scheduled imaging detects obstructions and environmental wear earlier.

Business Outcomes

- Higher compliance, lower risk: Consistent monthly inspections aligned to NFPA 10 and OSHA 1910.157 with audit-ready photo evidence and automatic date tracking (annual, internal exam, hydrostatic).

- Fewer misses, faster resolution: Immediate alerts for low pressure, missing pins/seals, damage, or blocked access reduce exposure windows.

- Increased throughput and labor efficiency: Inspect more units with the same team; redeploy specialists to high-value maintenance rather than rote checks.

- Less rework and warranty cost: For manufacturers/service centers, assembly verification prevents field failures and returns.

- Enterprise visibility: Unified dashboards show compliance status by site/zone, upcoming due dates, and recurring defect patterns to target preventive actions.

- Stronger audit posture: Time-stamped images, OCR’d tags, and rule-based pass/fail criteria create defensible records for insurers, AHJs, and internal safety audits.

Bringing it all together:

- Start with a pilot on a high-density area (e.g., packaging, warehouse, or maintenance corridors).

- Train models on your extinguisher mix (ABC, CO2, Class K) and tag formats; encode site rules (clearance, height, signage).

- Integrate with your CMMS so failures auto-create work orders and due dates sync.

- Validate performance with a short MSA study, then scale site-wide.

With ai computer vision embedded into your safety program, fire extinguisher visual inspection becomes a reliable, data-driven process. The result is simple: better compliance, fewer surprises, and documented proof that every unit will work when it’s needed most.

See It in Action

Explore the OV80i and ask us about advanced inspection packages for your specific application.