Steel Strip Surface Defect Detection with AI Vision

In steel manufacturing, surface defects can compromise product quality and lead to costly downstream failures. Traditional manual inspection methods struggle to keep pace with high-speed production lines, often missing critical defects until it's too late. AI-powered vision inspection is transforming how steel manufacturers detect and prevent surface defects in real-time.

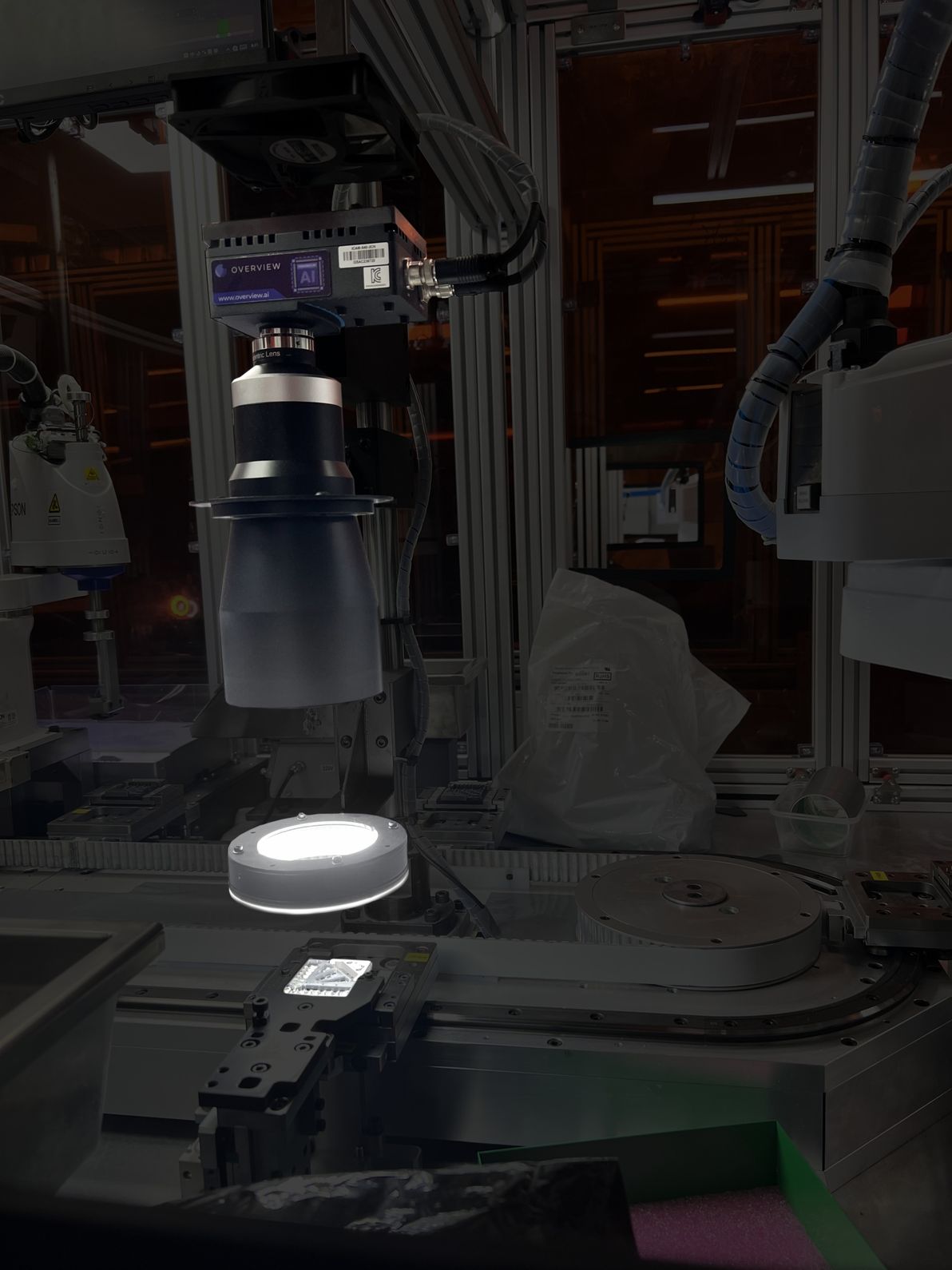

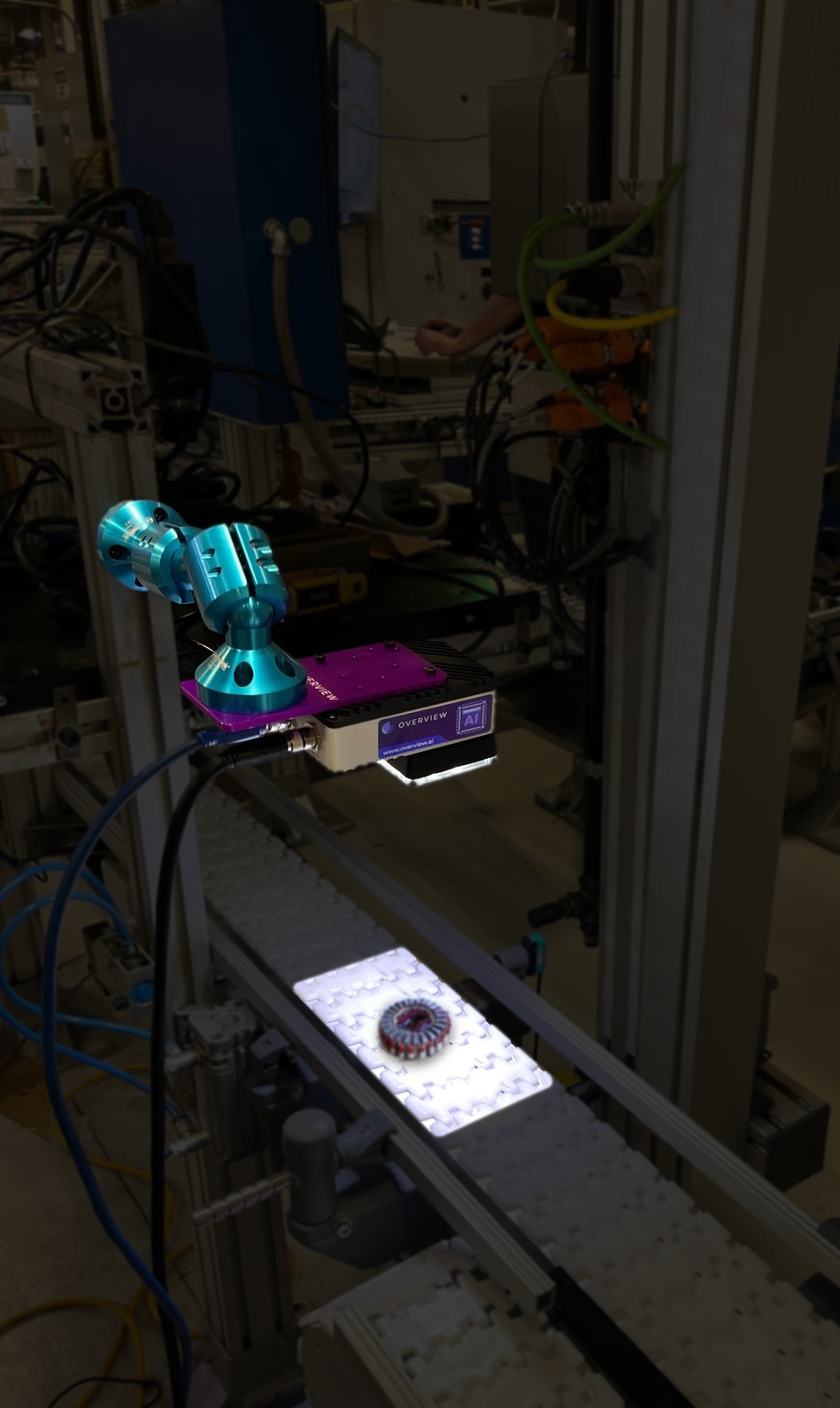

AI vision systems detect surface defects on steel strips with micron-level precision.

Common Steel Strip Surface Defects

Steel strip production involves multiple processes where defects can occur. Understanding these defect types is critical for implementing effective inspection strategies:

Surface Scratches

Linear marks caused by contact with rollers, guides, or other steel surfaces during processing. Can range from minor cosmetic issues to deep gouges that affect structural integrity.

Pits and Pinholes

Small depressions or holes in the surface caused by oxidation, scale formation, or material defects. Often difficult to detect visually but can lead to corrosion.

Edge Cracks

Fractures along the edges of the strip caused by excessive tension, improper cutting, or material brittleness. Critical defects that can propagate during forming.

Roll Marks

Periodic patterns or indentations caused by worn or damaged rolling mill cylinders. Can affect surface finish and dimensional accuracy.

Scale & Oxidation

Oxide layer formations that appear as discoloration or rough patches. Indicates improper descaling or temperature control issues.

Lamination Defects

Separation between layers of steel caused by inclusions or improper bonding. Can appear as blisters or delamination on the surface.

Why Traditional Inspection Methods Fall Short

Manual inspection and traditional automated optical inspection (AOI) systems face significant limitations in steel strip production:

- Speed limitations: Production lines run at 10-30 meters per second—too fast for manual inspection

- Inspection fatigue: Human inspectors miss 20-30% of defects due to monotony and fatigue

- Reflective surfaces: Steel's high reflectivity creates challenging lighting conditions for traditional vision systems

- Subtle defects: Micron-level scratches and pits are nearly impossible to detect with the naked eye

- False positives: Rule-based systems flag harmless surface variations as defects, causing unnecessary line stops

Modern steel production lines require real-time inspection at speeds up to 30 meters per second.

AI Vision: The Game-Changer for Steel Strip Inspection

AI-powered vision systems leverage deep learning to overcome the limitations of traditional inspection methods. Here's how Overview.ai's technology transforms steel strip quality control:

Real-Time High-Speed Inspection

The OV80i vision system processes images at 30 frames per second while maintaining micron-level defect detection accuracy. Edge-based AI processing eliminates network latency, enabling:

- Sub-second decision making for instant pass/fail determination

- Continuous 100% inspection of the entire strip width

- Multi-camera setups for simultaneous top and edge inspection

Adaptive Learning for Complex Defects

Unlike rule-based systems that require manual threshold adjustments, AI models learn from examples:

- Distinguishes between harmless surface variations and true defects

- Adapts to different steel grades and surface finishes without reprogramming

- Improves accuracy over time as more production data is collected

- Handles varying lighting conditions and steel reflectivity

Advanced Segmentation for Precise Defect Mapping

The OV80i's segmentation capabilities provide pixel-level defect localization, enabling:

- Defect size measurement for automatic grade classification

- Position tracking to optimize cutting patterns and minimize scrap

- Heat maps showing defect distribution for process optimization

- Automatic defect classification (scratch vs. pit vs. crack)

Implementation: From Installation to Production

Deploying AI vision inspection for steel strip manufacturing is faster than you might expect:

Week 1: System Installation & Calibration

- • Mount cameras above the strip line with proper lighting

- • Configure field of view to cover full strip width

- • Integrate with PLC for trigger signals and defect outputs

- • Set up edge computing infrastructure

Week 2: Data Collection & Model Training

- • Collect images of good strips and known defect types

- • Label defects using browser-based annotation tool

- • Train initial AI model (typically 1-2 hours)

- • Validate model accuracy with test samples

Week 3-4: Production Pilot & Optimization

- • Run parallel inspection (AI + manual verification)

- • Fine-tune detection thresholds and sensitivity

- • Collect additional edge cases for model improvement

- • Transition to full autonomous operation

ROI: The Business Case for AI Inspection

Steel manufacturers implementing AI vision inspection typically see ROI within 6-12 months through:

Cost Reductions

- • 50-70% reduction in scrap and rework

- • Elimination of manual inspection labor costs

- • Fewer customer returns and warranty claims

- • Reduced downtime from false alarms

Revenue Growth

- • Premium pricing for certified defect-free steel

- • Increased throughput from continuous inspection

- • New customer acquisition with quality guarantee

- • Improved yield from optimized cutting patterns

Case Study: Leading Steel Manufacturer

A Tier 1 steel producer reduced surface defect escapes by 92% and increased line throughput by 15% within 3 months of deploying Overview.ai vision inspection.

Key Specifications for Steel Strip Inspection

The OV80i system is specifically designed for demanding steel manufacturing environments:

Vision Capabilities

- • Resolution: Up to 80MP for micro-defect detection

- • Frame Rate: 30 FPS continuous inspection

- • Detection Size: Defects as small as 0.1% of FOV

- • Processing: NVIDIA Orin NX edge AI

Industrial Integration

- • I/O: Digital triggers and defect outputs

- • Protocols: Ethernet/IP, Profinet, Modbus

- • Environment: IP40 rated, 0-45°C operation

- • Lighting: Integrated LED illumination

Best Practices for Maximum Detection Accuracy

- Optimize Lighting Setup: Use directional lighting to enhance defect visibility on reflective steel surfaces. Low-angle lighting reveals scratches, while diffuse lighting works better for pits and surface irregularities.

- Multiple Camera Angles: Deploy cameras at different positions to inspect top surface, bottom surface, and edges simultaneously for comprehensive coverage.

- Continuous Model Improvement: Regularly review flagged defects and add edge cases to the training dataset to improve AI accuracy over time.

- Integration with MES: Connect inspection data to your Manufacturing Execution System for real-time quality analytics and process control.

- Operator Training: Train line operators on the browser-based interface for quick adjustments and troubleshooting without stopping production.

The Future of Steel Quality Control

AI vision inspection is evolving beyond simple pass/fail decisions. Next-generation capabilities include:

- Predictive maintenance: Detecting patterns that indicate equipment wear before defects occur

- Process optimization: Using defect data to automatically adjust rolling parameters

- Grade classification: Automatic sorting of steel strips based on surface quality

- Digital twins: Creating virtual models of production lines for simulation and optimization

Ready to Transform Your Steel Strip Inspection?

See how the OV80i can eliminate surface defects and increase your production quality.

Explore the OV80i System →Schedule a DemoRelated Articles

Roll Mark & Wrinkle Defect Detection with AI

Learn how AI vision systems detect roll marks, wrinkles, and surface defects in metal rolling processes with 99.8% accuracy.

Read More →

AI-Powered Weld Defect Detection

Achieve 99.5% accuracy detecting weld porosity, cracks, and incomplete fusion at 30 FPS for automotive and aerospace applications.

Read More →

Sensor Quality Inspection with AI Vision

Inspect sensor components for defects, contamination, and assembly errors with AI-powered vision systems.

Read More →