AI-Powered Weld Defect Detection: Porosity, Cracks & Incomplete Fusion

Weld defects cost manufacturers billions annually in rework, scrap, and warranty claims. A single undetected crack in an automotive body weld can lead to catastrophic failure. A porosity defect in an aerospace component might not appear until the part is in service. Traditional inspection methods—visual examination, X-ray, and ultrasonic testing—are slow, expensive, and often catch defects too late in the production cycle.

AI-powered vision inspection is revolutionizing weld quality control by detecting defects in real-time, at the point of welding, with accuracy that surpasses human inspectors and traditional automated methods.

Critical Weld Defects That AI Can Detect

Different welding processes—laser welding, resistance spot welding, arc welding—produce different defect signatures. Here are the most critical defects that impact structural integrity and product quality:

1. Porosity & Gas Pockets

Cause: Gas trapped in molten weld pool during solidification, often from contamination, improper shielding gas, or moisture.

Impact: Reduces weld strength by 30-50%, creates stress concentration points, and can lead to premature failure.

AI Detection: Identifies surface porosity visually and subsurface voids through thermal imaging analysis during the weld cooling phase.

2. Cracks (Hot & Cold)

Cause: Thermal stress during cooling (hot cracks) or hydrogen embrittlement (cold cracks). Material selection and welding parameters are critical factors.

Impact: Can propagate over time, leading to catastrophic structural failure. Zero tolerance in aerospace and pressure vessel applications.

AI Detection: Detects micro-cracks as small as 50 microns using high-resolution imaging and pattern recognition algorithms trained on thousands of crack examples.

3. Incomplete Fusion & Penetration

Cause: Insufficient heat input, improper joint preparation, or contamination preventing complete melting and fusion of base materials.

Impact: Creates weak joints that fail under load. Common in thick materials or multi-pass welds.

AI Detection: Analyzes weld bead geometry, surface texture, and heat-affected zone characteristics to identify fusion defects.

4. Spatter & Surface Contamination

Cause: Excessive welding current, improper gas flow, or contaminated base material causing molten metal ejection.

Impact: Cosmetic defects for Class A surfaces, potential corrosion sites, and interference with subsequent coating processes.

AI Detection: Identifies spatter patterns, size, and distribution to determine weld parameter optimization needs.

5. Undercut & Overlap

Cause: Excessive travel speed or incorrect welding angle creating grooves (undercut) or excess material buildup (overlap).

Impact: Stress concentration points that reduce fatigue life. Overlap can interfere with part assembly.

AI Detection: Measures weld profile using 3D imaging or laser profilometry integrated with AI analysis.

Why Traditional Weld Inspection Methods Are Inadequate

The High Cost of Late Detection

A weld defect caught during visual inspection after the part has moved downstream costs 10x more to fix than if caught at the point of welding. If the defect makes it to final assembly, the cost multiplies by 100x. If it reaches the customer, the cost can exceed 1000x when factoring in recalls, warranty work, and brand damage.

Traditional inspection methods face significant limitations:

Visual Inspection

- • Detects only surface defects

- • Subject to inspector fatigue and bias

- • Inconsistent results between shifts

- • Too slow for high-volume production

- • Misses micro-defects below visual threshold

X-Ray Inspection

- • Expensive equipment and operation

- • Safety concerns with radiation

- • Slow throughput (minutes per weld)

- • Requires trained radiography technicians

- • Cannot be done inline at production speed

Ultrasonic Testing

- • Requires coupling medium and surface preparation

- • Limited to accessible weld locations

- • Slow scan speeds

- • Difficult to automate for complex geometries

- • High equipment and operator training costs

Destructive Testing

- • Destroys sample parts

- • Provides only statistical quality data

- • Defects may occur between test samples

- • Expensive for low-volume production

- • Results lag production by hours or days

How AI Vision Transforms Weld Inspection

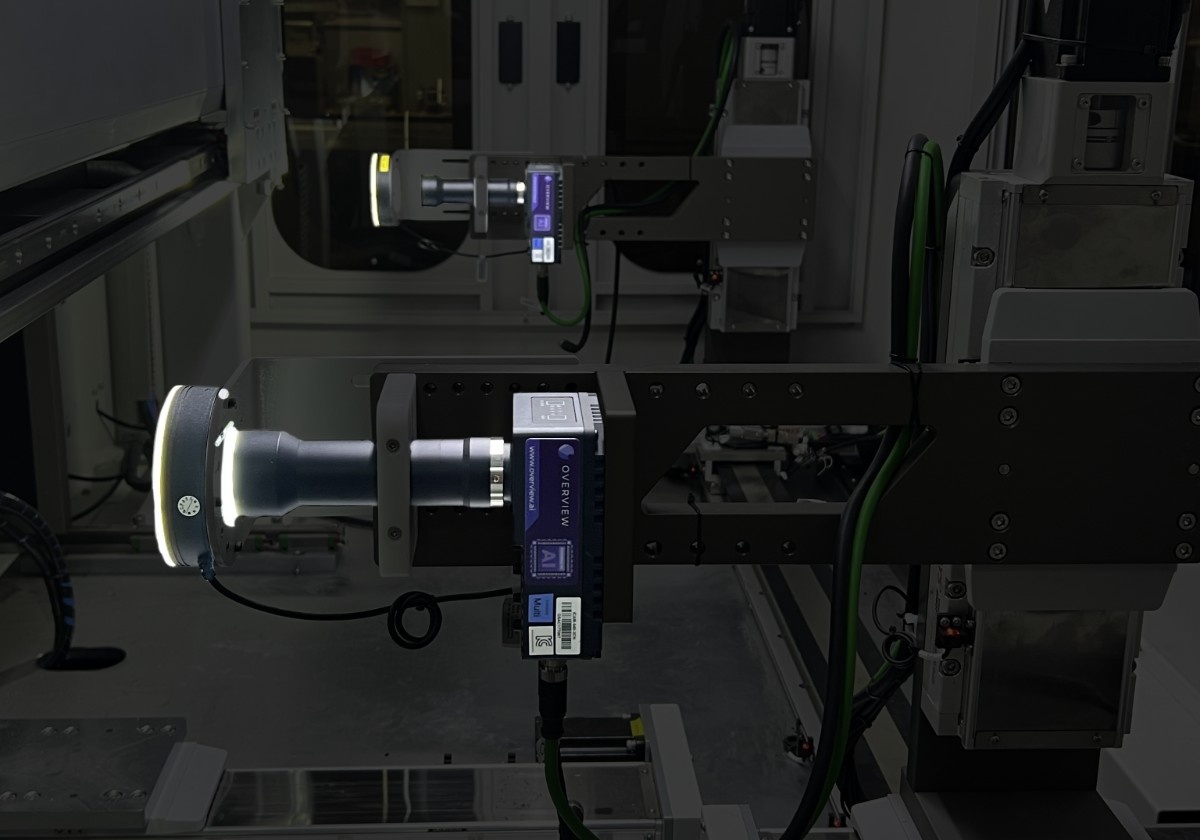

The Overview.ai OV80i vision system brings together advanced hardware, edge AI processing, and deep learning algorithms specifically trained for weld defect detection:

Real-Time Inline Inspection

Unlike offline inspection methods, AI vision operates at the point of welding:

- Immediate feedback: Defects detected within 100ms of weld completion

- 100% inspection: Every weld verified, not just statistical samples

- Process control integration: Automatic welding parameter adjustment based on defect trends

- Reduced scrap: Bad welds identified before additional value-add operations

Multi-Modal Sensing for Comprehensive Detection

The OV80i supports multiple imaging modalities that can be combined for maximum detection accuracy:

- High-resolution RGB imaging: Captures surface defects, spatter, and weld bead geometry with 8MP resolution

- Thermal imaging integration: Monitors weld pool temperature and cooling rate to predict subsurface defects

- Structured light 3D: Measures weld profile, penetration depth, and dimensional accuracy

- Multi-angle capture: Up to 4 synchronized cameras for complete weld inspection coverage

Deep Learning Models Trained on Millions of Welds

Overview.ai's weld defect models are pre-trained on extensive datasets and can be fine-tuned for your specific application:

Industry Applications & Success Stories

Automotive: Body-in-White Spot Weld Inspection

Challenge: Automotive manufacturers perform 3,000-5,000 resistance spot welds per vehicle. Manual inspection is impossible at production volumes. X-ray sampling misses defects between sample points.

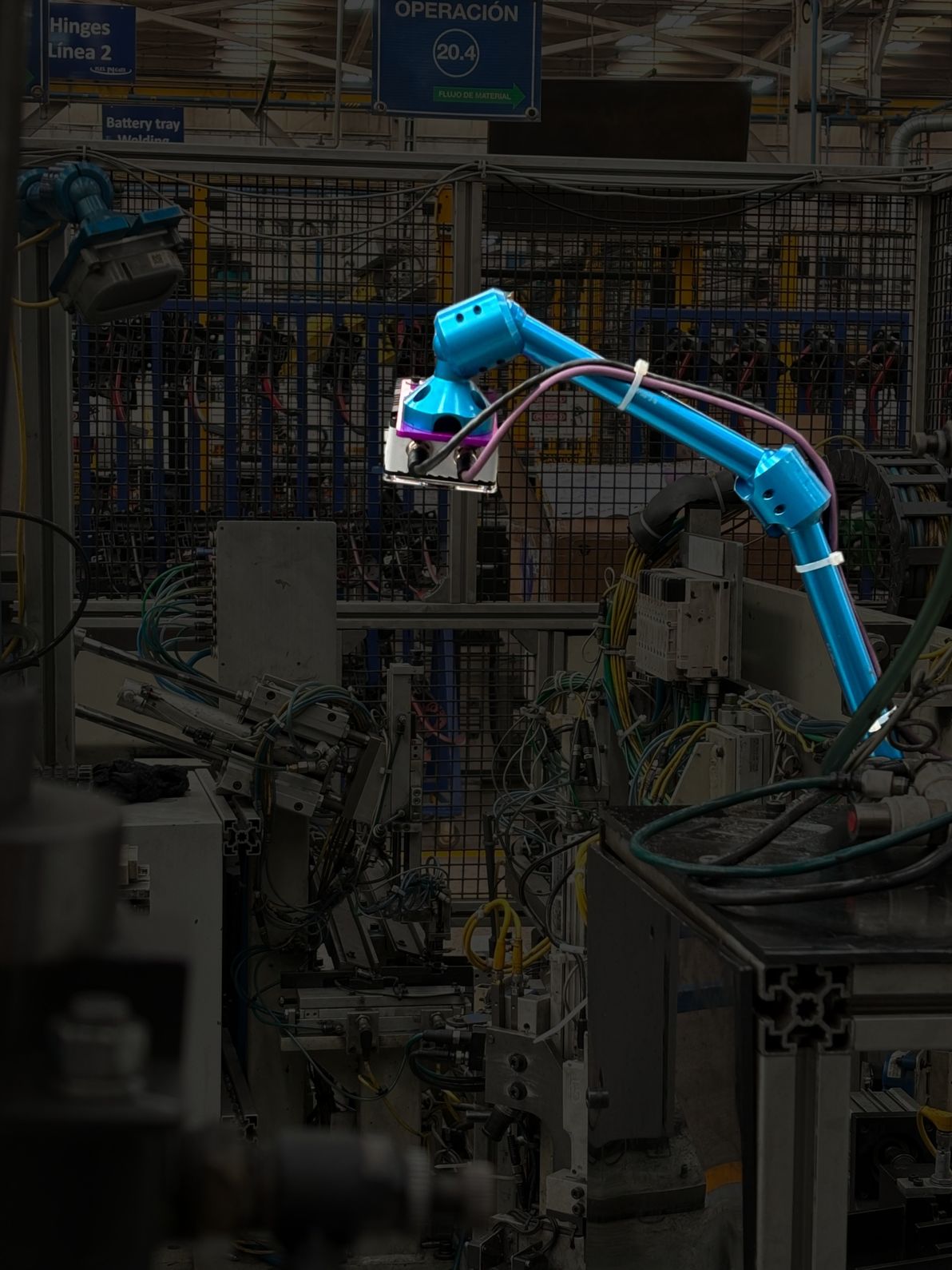

Solution: AI vision systems inspect every spot weld nugget diameter and indentation depth in real-time. Integration with robotic welding cells enables automatic rework of defective welds before the body moves to the next station.

Results: 94% reduction in downstream weld failures, 15% reduction in overall body manufacturing time, ROI achieved in 4 months.

Aerospace: Laser Weld Seam Integrity

Challenge: Aerospace components require hermetic seals with zero defects. Traditional dye penetrant testing takes hours and provides only pass/fail results without defect characterization.

Solution: Multi-camera OV80i setup captures weld seam from multiple angles during and immediately after laser welding. AI detects micro-cracks, porosity, and incomplete fusion in real-time.

Results: 100% inline inspection replacing sampling methods, 80% reduction in inspection labor, comprehensive defect data for process optimization.

Heavy Equipment: Structural Weld Quality

Challenge: Heavy equipment manufacturers need to verify thick-section welds in frames and chassis. Ultrasonic testing is slow and operator-dependent.

Solution: AI vision combined with thermal imaging during multi-pass welding provides real-time feedback on penetration depth and potential fusion defects between passes.

Results: 60% faster inspection cycle, improved first-pass weld quality, reduced need for destructive testing.

Implementation Roadmap

Deploying AI weld inspection typically follows this timeline:

Phase 1: System Design & Integration (Week 1-2)

- • Site survey to determine camera placement and lighting requirements

- • PLC integration design for weld cell communication

- • Mounting hardware fabrication and installation

- • Edge computing infrastructure setup

Phase 2: Data Collection & Model Training (Week 3)

- • Capture images of good welds and known defect types

- • Label training data using browser-based annotation tool

- • Train custom AI model (1-2 hours compute time)

- • Validate model accuracy against held-out test set

Phase 3: Production Validation (Week 4-5)

- • Run AI inspection in parallel with existing quality checks

- • Compare AI results to destructive testing and manual inspection

- • Fine-tune detection thresholds and sensitivity

- • Train operators on system interface and alert handling

Phase 4: Full Production Deployment (Week 6+)

- • Transition to autonomous inline inspection

- • Integrate defect data with MES and quality management systems

- • Implement automatic process control based on defect trends

- • Continuous model improvement with production data

Technical Specifications for Weld Inspection

Hardware Capabilities

- • Cameras: Up to 4x 8MP global shutter sensors

- • Frame Rate: 30 FPS per camera (120 FPS total)

- • Resolution: Detect defects down to 50 microns

- • Lighting: Integrated LED arrays with adjustable intensity

- • Processing: NVIDIA Orin NX 16GB edge AI

Software Features

- • Models: Pre-trained weld defect detection

- • Customization: Fine-tune for your weld types

- • Interface: Browser-based configuration and monitoring

- • Integration: REST API, MQTT, industrial protocols

- • Data: SQL database for defect history and analytics

ROI Calculation Example

Here's a realistic ROI scenario for a mid-size automotive supplier:

Annual Costs Before AI Vision

- • Rework & scrap from missed defects: $850K

- • Manual inspection labor (3 inspectors): $240K

- • X-ray sampling (equipment & operator): $120K

- • Customer returns & warranty: $380K

- Total Annual Cost: $1.59M

After AI Vision Implementation

- • System investment (2 cells): $180K

- • Annual software & support: $30K

- • Reduced rework (85% reduction): $128K

- • Reduced returns (90% reduction): $38K

- Net Annual Savings: $1.21M

- ROI Period: 5.3 months

Best Practices for Maximum Accuracy

- Optimize lighting for weld surface characteristics: Use low-angle directional lighting for crack detection, diffuse lighting for porosity, and coaxial lighting for laser weld inspection.

- Calibrate immediately after welding: Inspect while the weld is still warm to capture thermal signatures that indicate subsurface defects.

- Train models on actual production defects: While pre-trained models provide a starting point, fine-tuning with your specific materials, welding parameters, and defect modes improves accuracy significantly.

- Implement closed-loop control: Use defect trend data to automatically adjust welding parameters, preventing defects before they occur.

- Maintain comprehensive defect databases: Store all defect images and classifications for continuous model improvement and root cause analysis.

The Future: Predictive Weld Quality Control

The next generation of AI weld inspection goes beyond defect detection to predictive quality control:

- Weld parameter optimization: AI analyzes the relationship between welding parameters (current, voltage, travel speed) and defect rates to recommend optimal settings

- Equipment health monitoring: Detect patterns indicating electrode wear, shielding gas contamination, or other equipment issues before they cause defects

- Material traceability: Correlate defect rates with material lot numbers to identify problematic batches

- Digital twin integration: Combine AI vision data with welding simulation models to predict weld quality in new designs

Ready to Eliminate Weld Defects?

See how the OV80i can transform your welding quality control with 100% defect detection accuracy.

Explore the OV80i System →Schedule a DemoRelated Articles

Battery Laser Welding Defect Detection

Inspect battery cell welds for porosity, spatter, and incomplete fusion with AI vision. Critical for EV battery safety and reliability.

Read More →

Steel Strip Surface Defect Detection

Detect scratches, pits, and edge cracks on steel strips with 99.9% accuracy at production speeds.

Read More →

Reduce Automotive Defects with AI

Learn how AI vision reduces automotive defects by 90% across stamping, welding, and assembly operations.

Read More →