Tableting Defects in Pharmaceutical Manufacturing (and How to Prevent Them)

Tablet production is a critical stage in pharmaceutical manufacturing. Even with advanced machinery and strict GMP guidelines, defects like cracks, chips, coating issues, and misprints still occur. These defects not only generate waste and increase cost, but—most crucially—risk patient safety and damage trust.

If you've ever searched for "common tablet defects" or "pharmaceutical tablet inspection solutions," you know how challenging it is to maintain defect-free lines. To combat this, manufacturers are increasingly using AI-powered, 100% visual inspection systems to catch every error in real time.

In this article, we'll walk through the most common tablet defects, their causes, how to prevent them, and how Overview.ai offers a solution more accurate and efficient than traditional methods.

Tableting Defects in Pharmaceutical Manufacturing

1. Capping & Lamination

What it looks like: Tablets split horizontally (capping) or break into multiple layers (lamination).

Causes: Excess compression force, high turret speed, weak binders, or low moisture.

Prevention Tips: Adjust turret speed, improve binder quality, and maintain optimal moisture content.

Manufacturing Impact: High rejection rate and downtime; cleaning/repunching increases cost.

2. Chipping

What it looks like: Tablet edges break or chip off.

Causes: Worn punches/dies, excess concavity, overly wet granules, or poor lubrication.

Prevention Tips: Replace worn tooling, check lubrication levels, and ensure granules are dried properly.

3. Binding

What it looks like: Tablets stick to the die wall during compression.

Causes: Rough dies, high compression pressure, abrasive materials, excess moisture.

Prevention Tips: Smooth or replace tooling, optimize compression settings, and use high-quality lubricants.

4. Picking

What it looks like: Material sticks to the punch face, leaving small pits.

Causes: Moisture, weak binders, insufficient lubrication; often worse on engraved punches.

Prevention Tips: Improve drying, use stronger binders, and optimize lubrication for engraved tooling.

5. Contaminants (Dots/Dirt)

What it looks like: Black, dark, or colored specks on the tablet surface.

Causes: Lubricant contamination, die abrasion, dirty raw materials, or feeder misadjustments.

Prevention Tips: Improve raw material screening and feeder calibration, and monitor die wear closely.

6. Thickness Variation

What it looks like: Tablets are uneven in thickness.

Causes: Uneven punch lengths, poor blend uniformity, or inadequate press maintenance.

Prevention Tips: Regularly calibrate press equipment and monitor blend homogeneity.

7. Irregular Shape

What it looks like: Tablets are misshapen or distorted.

Causes: Excess press speed, damp granules, or insufficient pre-compression.

Prevention Tips: Reduce press speed, optimize drying, and ensure pre-compression is adequate.

Coating Defects in Pharmaceutical Manufacturing

8. Cracking

What it looks like: Cracks form on the coated surface.

Causes: Overheating, brittle coating film, poor spray/drying conditions.

Prevention Tips: Adjust pan speed and drying temperature, and improve coating elasticity.

9. Sticking / Satellites

What it looks like: Tablets stick together, or small fragments attach during coating.

Causes: Over-wetting, incorrect spray rate, misaligned spray guns, insufficient curvature.

Prevention Tips: Calibrate spray settings, adjust pan rotation, and optimize tablet shape.

10. Color Variation

What it looks like: Uneven or patchy coloring.

Causes: Uneven spray application, low coating suspension solids, or small batch sizes.

Prevention Tips: Maintain suspension consistency and ensure proper spray gun alignment.

11. Dark Spots

What it looks like: Black or brown marks on the tablet surface.

Causes: Long coating times, abrasive pigments (e.g., titanium dioxide), pan wall wear.

Prevention Tips: Use smoother pigments, avoid over-coating, and maintain coating pans.

12. Damaged Print

What it looks like: Logos, numbers, or text are blurred or misaligned.

Causes: Misaligned punches, clogged print heads, poor ink/coating compatibility.

Prevention Tips: Align and clean equipment regularly, and test ink-coating compatibility.

Why These Defects Really Matter

Regulatory Pressure & Recalls: In FDA's FY2024 Report on the State of Pharmaceutical Quality, recalls related to Current Good Manufacturing Practice (CGMP) deficiencies made up ~24% of all recall events.

Product Quality Defect Reports: The FDA tracks Product Quality Defects (PQDs) via field alert reports, MedWatch, etc., which show quality issues remain a consistent cause of enforcement actions.

Drug Shortages: Quality/manufacturing defects are repeatedly singled out as one of the top reasons for drug shortages. In FY2023, the FDA notes that quality problems remain among the most common causes of shortages.

Why Traditional Inspections Fall Short

- Manual inspection: Inconsistent, slow, prone to human error.

- Sampling methods: Miss defects since only a fraction of tablets are checked.

- Competitor systems: Often rely on outdated imaging, missing subtle coating flaws.

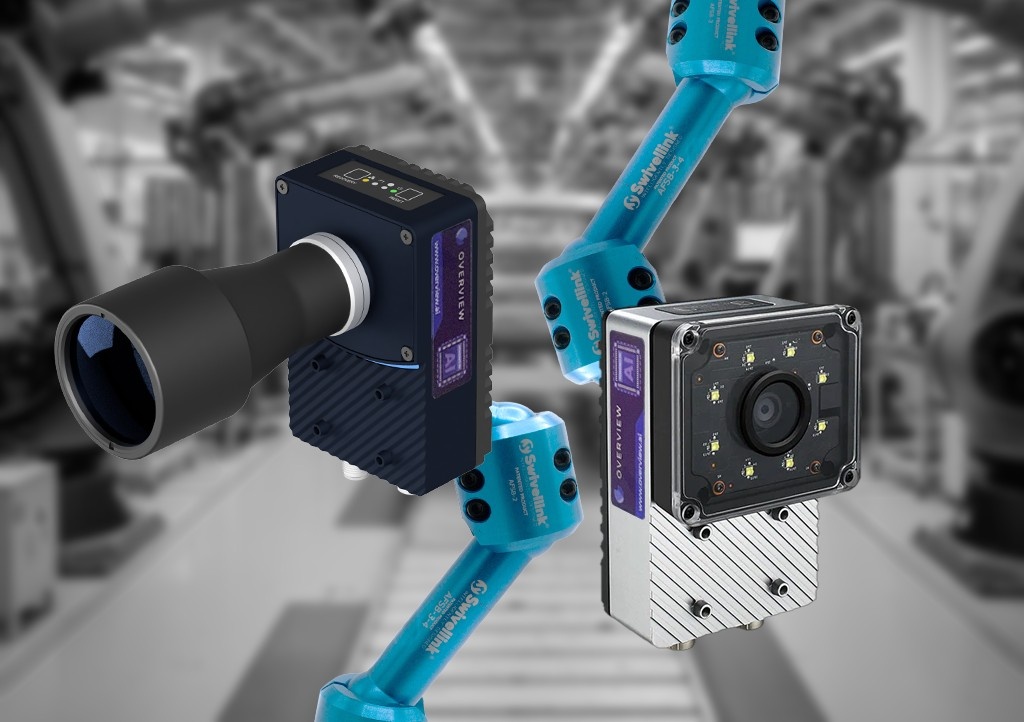

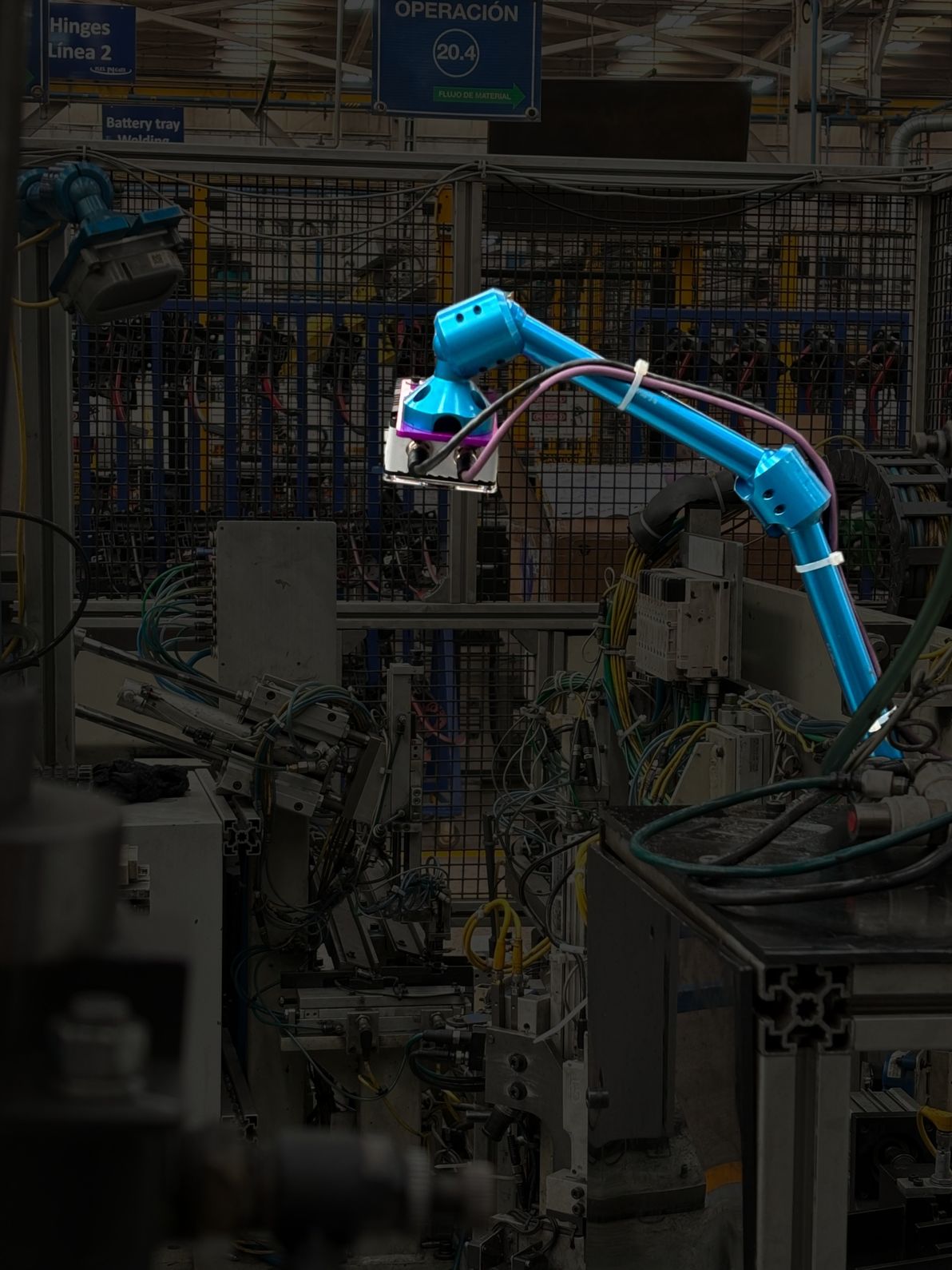

How Overview.ai Solves Tablet Defects

Overview.ai offers an AI-powered, 100% visual inspection system that outperforms traditional methods:

- ✅100% accuracy at production speed — every tablet is inspected, not just a sample.

- ✅Detects surface and hidden defects with AI-driven precision.

- ✅Faster setup & more reliable than competitor systems.

- ✅Meets GMP, FDA, and EMA compliance standards.

With Overview.ai, pharmaceutical manufacturers reduce waste, ensure compliance, and guarantee patient trust.

HAVING TROUBLE WITH DEFECTS ON TABLETS?

Our AI-powered visual inspection systems can help you detect and eliminate defects with 100% accuracy at production speed.

Related Articles

Medical Device Micro-Scratch Inspection

Detect surface defects on medical devices with AI vision. Ensure regulatory compliance.

Read More →

Blister Pack Inspection with AI

Inspect pharmaceutical blister packs for defects, contamination, and seal quality.

Read More →

Achieving 100% Accuracy in AI Vision

Learn how to achieve 100% defect detection accuracy in pharmaceutical manufacturing.

Read More →