Metal Stamping Defect Detection with AI Vision Inspection - 100% Accuracy

Real-time automated inspection detects cracks, splits, burrs, and surface defects in stamped metal parts during production. Reduce scrap by 40%+ with AI-powered quality control.

Why Manual Metal Stamping Inspection Misses 15-30% of Critical Defects

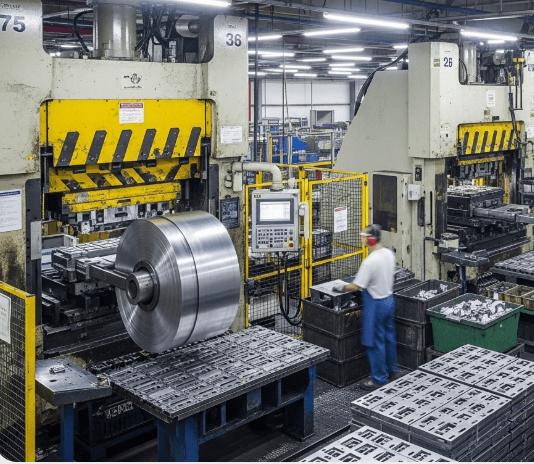

High-speed progressive die and transfer stamping operations produce thousands of parts per hour. Manual quality inspection can't keep pace—resulting in defects reaching assembly lines, costly rework, and customer returns in automotive, appliance, and industrial manufacturing.

Inspection Bottlenecks

Manual inspection slows production and still misses micro-cracks and subtle defects

Costly Scrap & Rework

Undetected defects cost thousands in scrapped parts and downstream rework

Reflective Surface Challenges

Shiny metal surfaces create glare making traditional vision systems unreliable

AI-Powered Metal Stamping Inspection: Real-Time Defect Detection at Production Speed

Our automated AI vision inspection system identifies stamping defects in real-time with 100% accuracy, reducing scrap rates by 40%+ and inspection time by 75%—without slowing down your progressive die or transfer press operations.

High-Speed Inspection

Inspect every part at full production speed without bottlenecks

Catches Micro-Defects Humans Miss

Detects cracks as small as 0.1mm, pre-splits, and subtle surface irregularities

Real-Time Production Analytics

Track defect trends by type, die set, and shift for continuous improvement

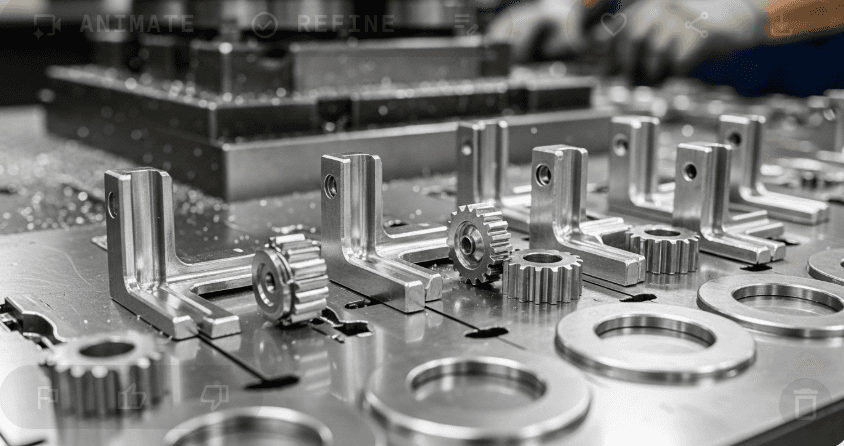

Comprehensive Stamping Defect Detection: 6 Critical Defect Types

Deep learning computer vision models trained on millions of metal stamping defects detect and classify cracks, splits, burrs, surface defects, deformation, die forming issues, and dimensional errors in real-time across automotive, appliance, and industrial stamping operations

Cracks & Splits

- •Through cracks

- •Partial splits

- •Pre-splits & micro-cracks

- •Edge cracks

Surface Defects

- •Scratches & gouges

- •Surface irregularities

- •Pitting & corrosion

- •Wrinkles & folds

Burrs & Edge Defects

- •Burrs & sharp edges

- •Incomplete cuts

- •Edge rollover

- •Shear marks

Deformation & Shape

- •Bending & twisting

- •Necking & thinning

- •Warping & distortion

- •Spring-back issues

Die Forming Issues

- •Incomplete forming

- •Die marks & impressions

- •Tool wear indicators

- •Misalignment defects

Dimensional Errors

- •Over/under thickness

- •Hole position errors

- •Edge distance violations

- •Trim line deviations

Proven ROI: Metal Stamping Quality Control Results

Automotive, appliance, and industrial manufacturers using AI stamping inspection report immediate quality improvements and cost savings

Get Started with AI Metal Stamping Inspection

Schedule a demo to see how Overview's automated AI vision inspection system can reduce scrap rates, eliminate manual inspection bottlenecks, and improve quality control in your progressive die, transfer press, or deep draw stamping operations. ROI in as little as 1 month.