Built for Your Team to Run

Manufacturing engineers configure systems. Operators execute inspections. No computer vision specialists required.

Modular Optical Hardware

Build inspection systems tailored to your application. Interchangeable components adapt to changing production requirements without complete system replacement.

Integrated Lighting Options

The OV10i and OV20i offer compact, integrated camera solutions perfect for space-constrained applications.

Interchangeable C-Mount Lenses

The OV80i features standard C-mount interface supporting any industrial lens—from macro inspection to long working distance applications. Change lenses in seconds without tools.

Integrated lighting solutions include:

- •Ring lights: Uniform illumination for flat surface inspection

- •Dome lights: Diffuse lighting eliminates glare on reflective surfaces

- •Backlights: Silhouette imaging for dimensional measurement and edge detection

Customizable Dashboards

Build role-specific interfaces with standard web technologies. No proprietary tools or vendor lock-in for UI development.

HTML/CSS/JavaScript

Standard web stack means your IT teams or web developers build custom interfaces. No specialized training or proprietary frameworks required.

Role-Specific Views

- •Operators: Simplified pass/fail screens with defect annotations

- •Engineers: Detailed analytics, model performance metrics, and retraining tools

- •Management: Production KPIs, quality trends, and ROI dashboards

Browser-Based Access

Access from any device on your network. No client software installations. IT teams control access through standard network security.

Native Industrial Protocols

Communicate directly with PLCs and factory automation systems. No middleware or protocol converters required.

Built-In Protocol Support

- •EtherNet/IP: Rockwell/Allen-Bradley ecosystem integration

- •Profinet: Siemens PLC communication

- •Modbus TCP: Universal industrial standard

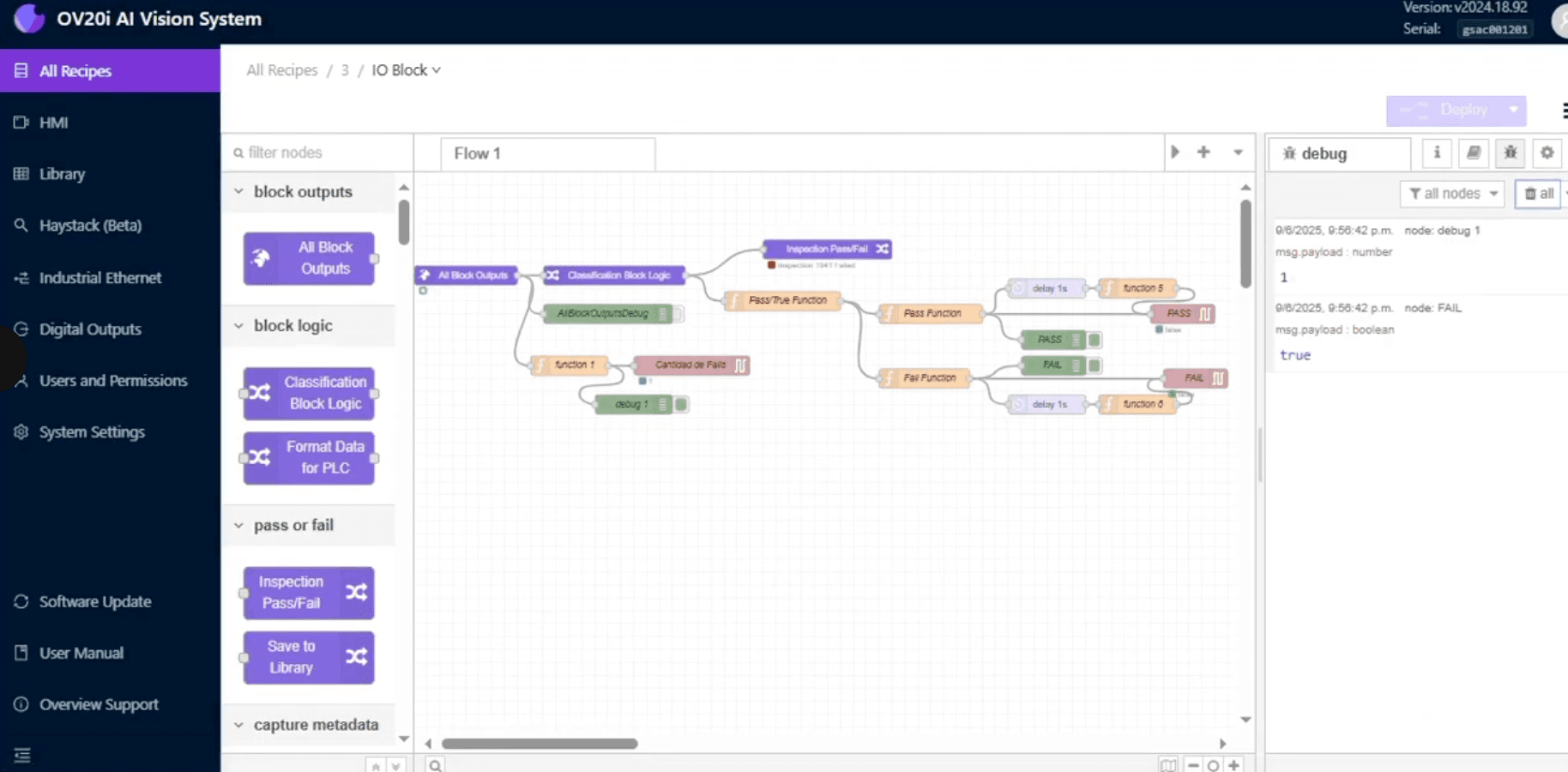

Node-RED for Custom Logic

Visual programming environment runs on every camera. Build custom integration logic without traditional coding:

- •Trigger inspections from PLC signals or production events

- •Send defect data to MES/ERP systems via REST APIs

- •Coordinate multi-camera inspection sequences

- •Implement custom business logic (defect counting, SPC calculations)

No Gateway Hardware

Direct PLC communication eliminates single points of failure. Each camera operates independently—no central server bottlenecks.

Ready to Empower Your Team?

Deploy AI vision systems your manufacturing teams can configure, operate, and maintain independently.