Overview AI vs Cognex: The Smarter Vision Solution

Faster setup, lower costs, and greater flexibility compared to Cognex In-Sight systems.

Modern AI Vision for Modern Manufacturing

While Cognex has been a leader in machine vision, Overview AI represents the next generation. Our AI-first platform eliminates the complexity, high costs, and rigid infrastructure of traditional systems.

Deploy in hours, not weeks. Overview AI offers rapid deployment, intuitive training, and seamless scalability.

No programming expertise required. Where Cognex needs specialized knowledge and complex setups, Overview AI empowers your team to achieve world-class results immediately.

Side-by-Side Comparison

| Feature | Overview AIWINNER | Cognex In-Sight |

|---|---|---|

| Setup Time | 1-3 Hours Browser-based, no installation required | Days to Weeks Requires programming and technical setup |

| Cost | $4.5K - $13.5K All-inclusive, predictable pricing | $10K - $50K+ Per installation, plus integration costs |

| Scalability | Edge-Based Architecture Instant deployment across lines | Hardware-Dependent New hardware per line required |

| Integration Ease | Plug & Play Browser interface, API-ready | Complex Requires EasyBuilder programming |

| AI Flexibility | Adaptive AI Train with 5 examples, continuous learning | Traditional Tools ViDi deep learning requires extensive training |

| Image Storage | Built-in Library JPEG compression, 75K-300K images | No Library Must offload immediately, BMP only |

| File Format | JPEG Efficient storage, ~100KB per image | BMP Only Massive file sizes, ~2-5MB per image |

| Maintenance | Minimal Over-the-air updates, remote support | Regular On-site maintenance, manual updates |

Setup Time

Cost

Scalability

Integration Ease

AI Flexibility

Image Storage

File Format

Maintenance

See the differences firsthand with a personalized demo

Why Manufacturers Choose Overview AI Over Cognex

We eliminate the traditional barriers of machine vision. Enterprise-grade inspection without the complexity or technical overhead.

Superior Accuracy, Proven Performance

Overview AI's deep learning models consistently deliver higher accuracy than traditional vision systems. Our advanced AI architecture detects defects that rule-based systems miss, with fewer false positives and faster inspection speeds.

Faster Time to Value

Deploy in 1-3 hours versus days or weeks with Cognex. Our browser-based interface eliminates EasyBuilder programming complexity and gets you inspecting parts immediately.

No specialized vision expertise required. If you can use a web browser, you can deploy Overview AI.

70% Lower Total Cost

Save up to $35K+ per installation compared to Cognex. No hidden licensing fees, no external storage infrastructure costs, no ongoing maintenance expenses.

Transparent all-inclusive pricing: $4.5K-$13.5K versus Cognex's $10K-$50K+ per line.

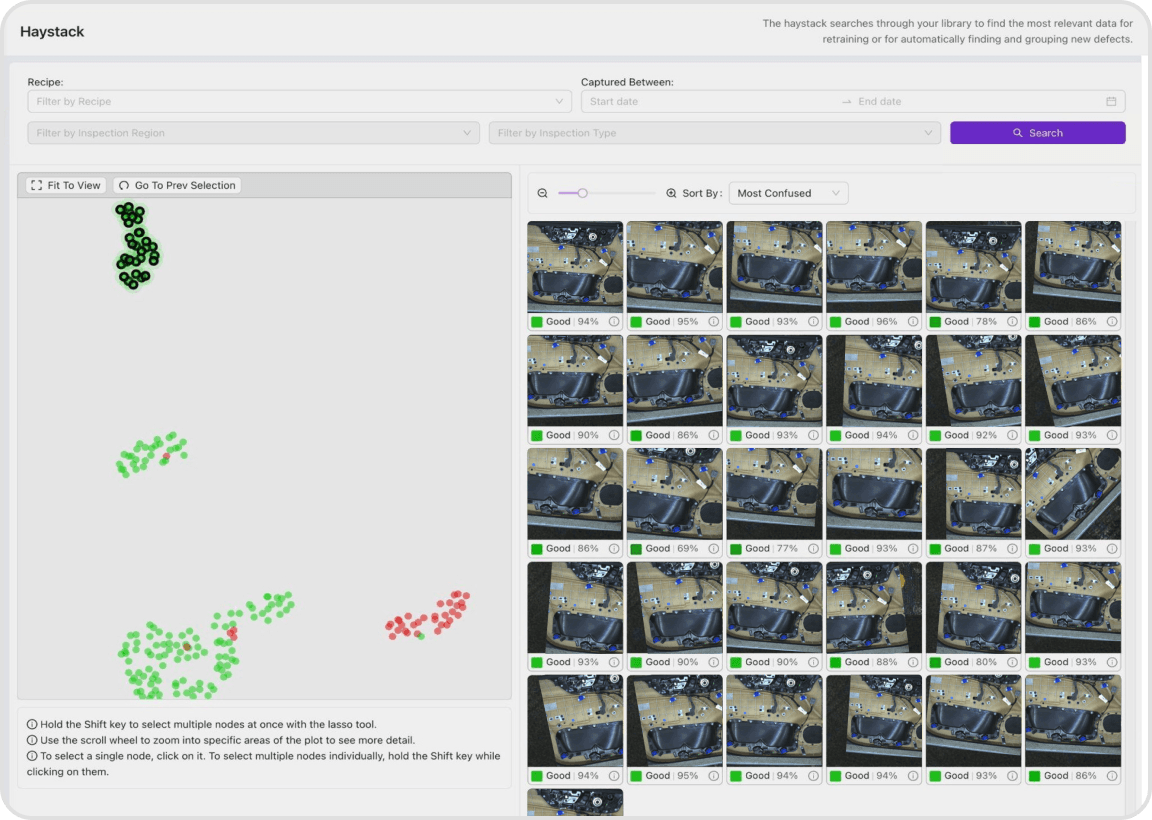

Built-in Image Library

Store 75K-300K images on-device with efficient JPEG compression. Unlike Cognex's forced BMP offloading, review and retrain anytime without external infrastructure.

JPEG saves 95%+ storage space versus Cognex's mandatory BMP format (100KB vs 2-5MB per image).

Adaptive AI - Minimal Training

Train production-ready models with just 5 examples in under an hour. Our advanced AI learns from minimal data and continuously improves.

Cognex ViDi requires hundreds of labeled examples for complex tasks. We deliver accuracy with 95% less training data.

No Programming Required

Zero EasyBuilder spreadsheet programming. No vision expertise needed. Your manufacturing team can set up and manage inspections independently.

Cognex requires specialized training and ongoing dependency on vision engineers. We eliminate that bottleneck entirely.

Edge-Based Architecture

Remote monitoring, centralized management, and real-time analytics across all facilities. All processing happens on-device with embedded NVIDIA GPUs for zero cloud dependency.

Cognex's traditional architecture lacks the modern network capabilities and edge AI processing for distributed manufacturing.

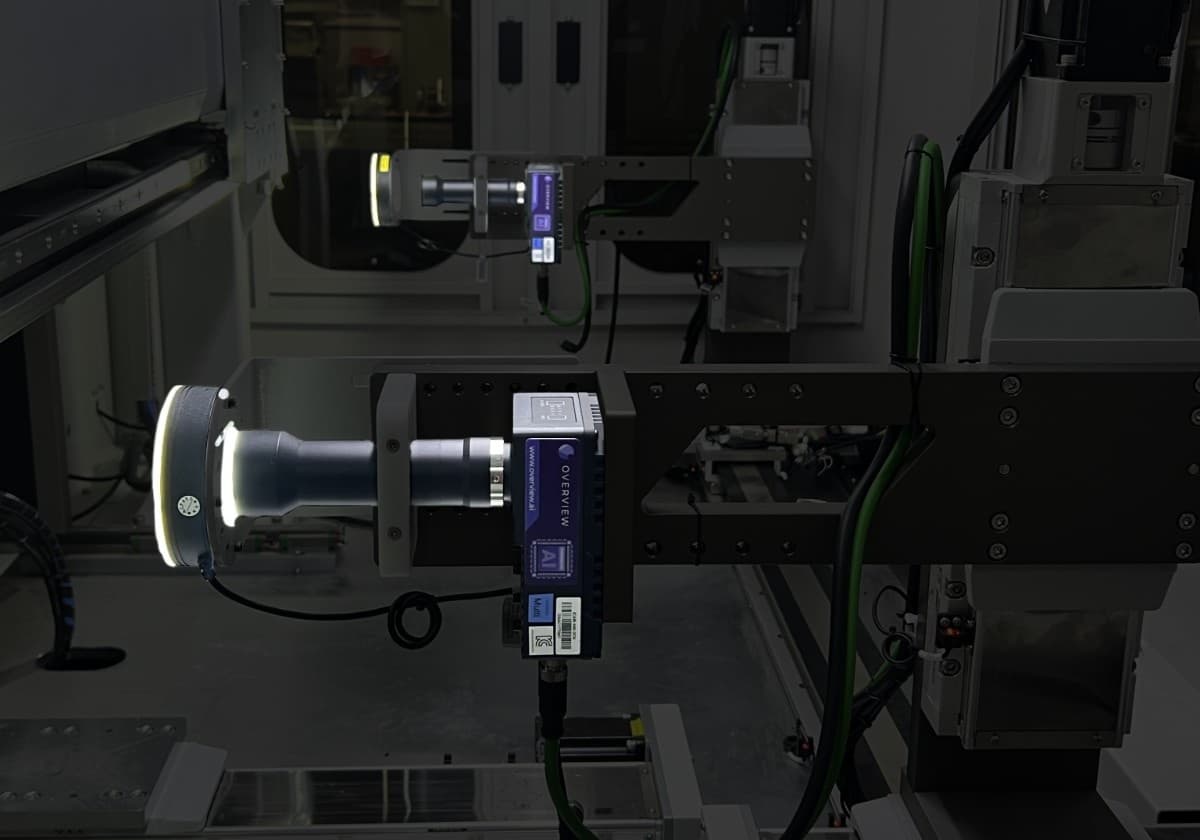

Overview AI Product Line

Simple, powerful vision systems for real manufacturing

OV10i Smart Camera

Classification-focused smart camera with integrated AI processing and lighting.

OV20i Smart Camera

All-in-one vision system with advanced segmentation capabilities and integrated lighting.

OV80i Vision System

High-performance system with customizable optics, multi-camera support, and best-in-class accuracy.

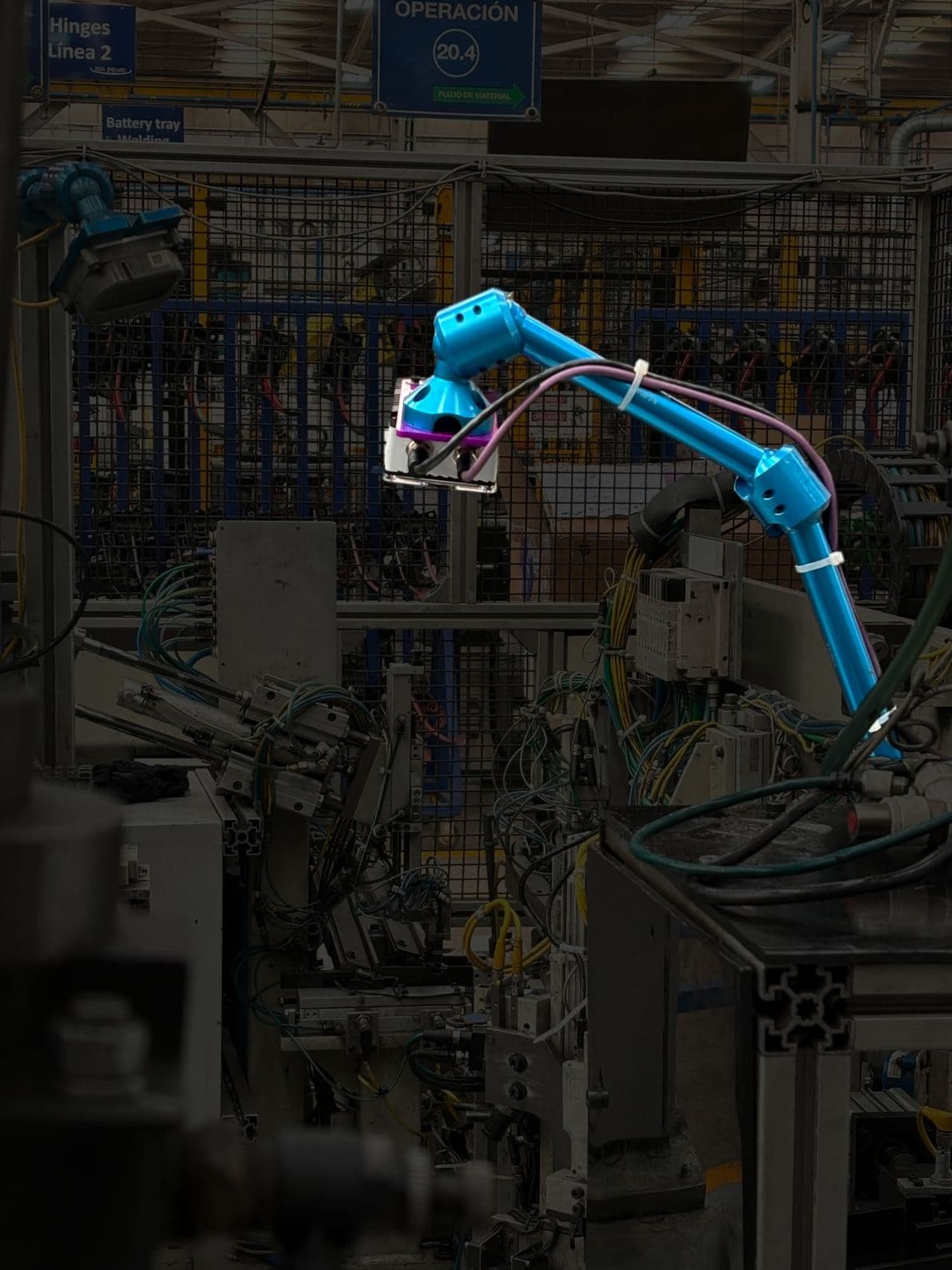

Overview AI in Action

Advanced Defect Detection

From microscale defects to complex assembly verification with minimal training

Real-Time Analysis

Instant defect detection at production speeds with built-in image storage and review.

Browser-Based Interface

No EasyBuilder programming. Simple, intuitive web interface anyone can use.

Complex Inspections

Handle complex assembly verification and multi-defect detection with ease.

Learn More About Overview AI

Our Products

Explore our complete line of AI vision systems: OV10i, OV20i, and OV80i.

Solutions

Discover industry-specific solutions and applications for your manufacturing needs.

Resources

Access case studies, documentation, and technical resources to get started.

Upgrade to Modern AI Vision with Overview AI

Join leading manufacturers switching from legacy systems. Experience faster deployment, lower costs, and superior flexibility.