Electronics Connector Assembly Verification

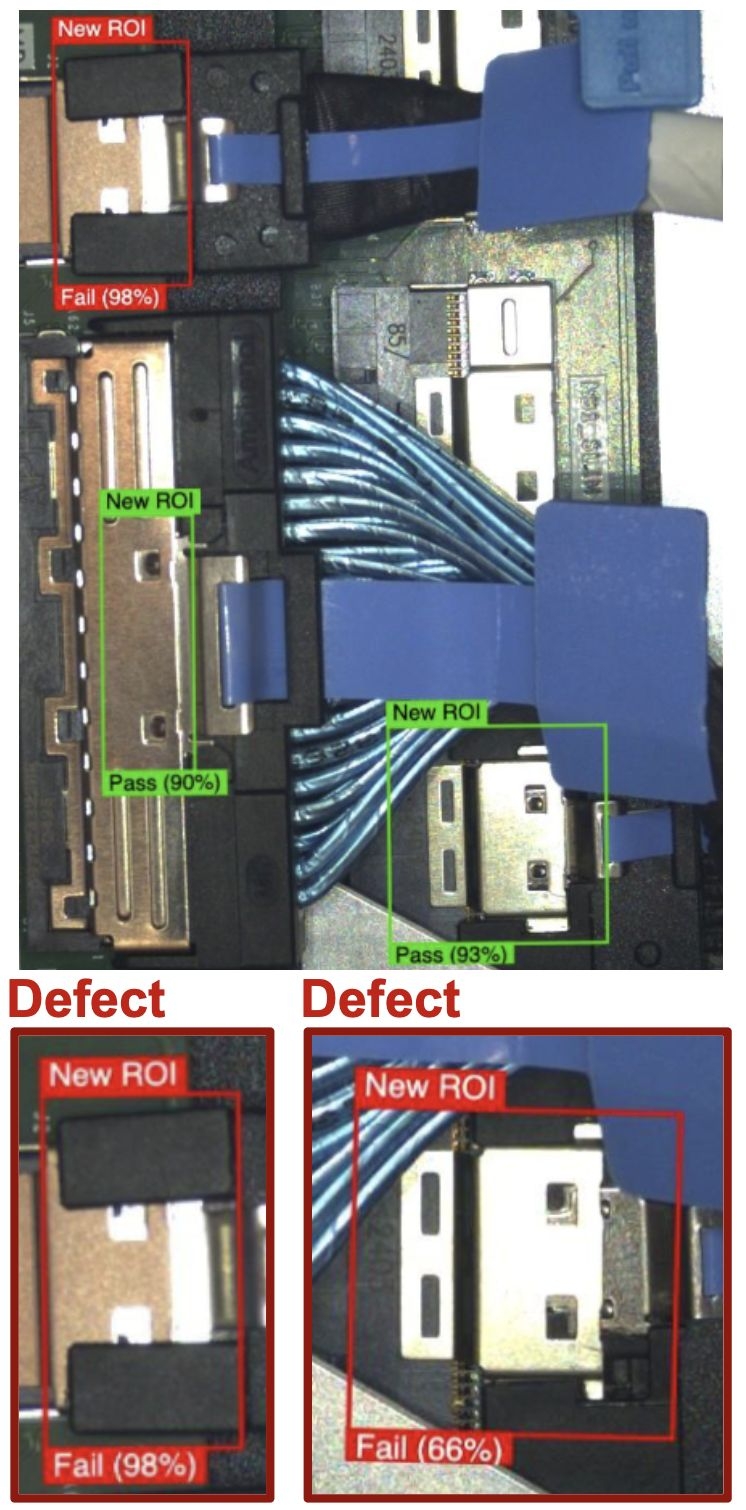

One of the largest electronics manufacturers needed an automated solution to inspect the proper assembly of complex connectors. There were multiple challenges: (1) verify multiple connections in one (connector, cable, and security latch). The defects were subtle and difficult to distinguish, with reflections & variable lighting increasing the challenge.

“The advances in this AI tool are really exciting. It seemed to be robust to the nuances of the connection and worked across variable conditions.”

— Manufacturing Engineer

The Challenge

Verifying proper assembly of multiple soft-seated connectors was extremely challenging. The customer needed to verify multiple connections in one inspection (connector, cable, and security latch). Defects were subtle and difficult to distinguish, with reflections and variable lighting increasing the difficulty.

Our Solution

We implemented a classifier algorithm trained on 10 images (5 good, 5 bad). The solution successfully trained all defect types in a single recipe and provided a confidence score for each inspection. This approach enabled the customer to accurately define pass/fail criteria & automate complex quality control process with 100% accuracy in highly variable conditions.

Application

- • PCB connector & component inspection

- • Soft-seated connector verification

- • 98% confidence threshold

Key Results

- • 100% accuracy across test samples

- • Single recipe for all defect types

- • Robust to variable conditions

Technical Implementation Details

Our engineering team deployed a comprehensive solution including hardware setup, camera configuration, alignment procedures, and AI model training...

Performance Results

Detailed testing results, accuracy metrics, ROI calculations, and deployment timeline...

Want to Read the Full Case Study?

Access our complete library of case studies, technical details, and implementation guides.

Access Full Case StudyFree download with email registration