High Voltage Wire Braid Inspection

A leading manufacturer of high-performance electrical wiring faced a tough quality control problem in coaxial wire braiding. Designed for biomedical & aerospace use, they must be defect free. Subtle defects like foreign object debris (FOD) and dents are hard to detect due to their size and variability and wire braid complexity.

The Challenge

Existing vision systems had high overkill rates, slowing production. The complexity of wire braid patterns, combined with reflective surfaces and variable defect sizes, made reliable detection extremely difficult. Traditional systems couldn't handle the variability.

Our Solution

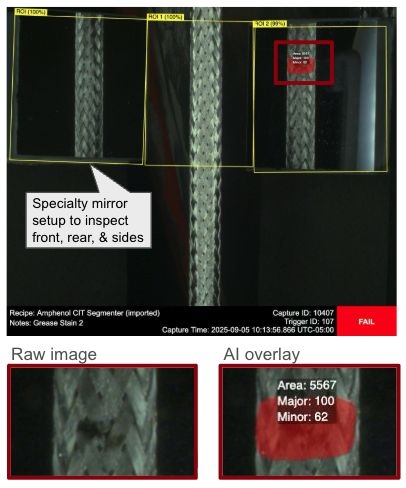

Overview AI implemented an AI segmentation model to reliably detect defects, no matter the current wire thickness. This model even worked on reflections of specialty first-surface mirrors to catch defects on the sides & backs, giving the solution 360 degree coverage. We developed a custom dashboard to communicate braiding issues so operators are armed with specific defect information to find & fix issues.

Application

- • Braided wire inspection

- • FOD and dent detection

- • Fast-moving production line

Key Results

- • 100% accuracy (extremely hard app!)

- • 360° defect coverage

- • Custom operator dashboard

Technical Implementation Details

Our engineering team deployed a comprehensive solution including hardware setup, camera configuration, alignment procedures, and AI model training...

Performance Results

Detailed testing results, accuracy metrics, ROI calculations, and deployment timeline...

Want to Read the Full Case Study?

Access our complete library of case studies, technical details, and implementation guides.

Access Full Case StudyFree download with email registration