OV20i Smart Camera

Compact All-in-One Solution

Compact, all-in-one vision system with integrated AI processing. Perfect for space-constrained environments and standalone applications with advanced segmentation capabilities.

Key Features

AI Processing (Segmentation)

Advanced built-in AI processing with full segmentation capabilities for detailed defect analysis and precise localization.

Browser Based Interface

No software installations required. Access and control your system through any web browser with intuitive controls.

Software Controlled Focus

Precisely control focus through software for optimal image capture across various inspection scenarios.

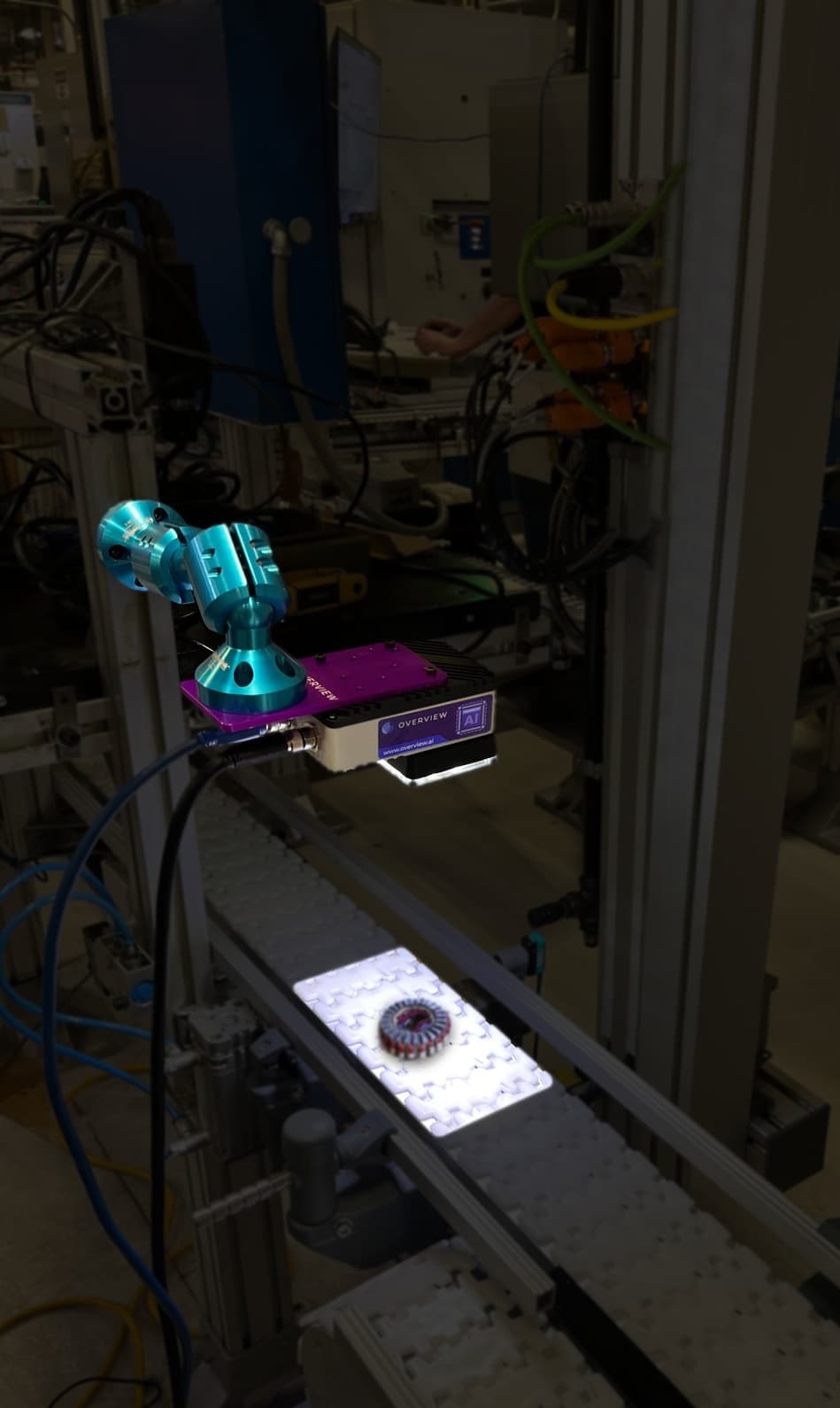

In Action

Technical Specifications

| Specification | Details |

|---|---|

| Inspection Algorithm | Classification and segmentation |

| Sensor | 1.6MP SONY IMX296 |

| Actual Resolution | 1408 x 1080 |

| Lens Options | 12mm variable focal; also 6, 8, 16, 25 mm |

| Lighting | Integrated LED ring |

| Trigger Modes | PLC Trigger, Hardware Trigger, Interval Trigger, Alignment Trigger |

| Number of Inputs / Outputs | 2 digital outputs and 2 digital inputs |

| Supported Industrial Protocols | Ethernet/IP, PROFINET, OPC UA |

| Processor | NVIDIA Xavier NX |

| AI Performance | 21 TOPS (INT8) |

| CPU | 6-core Carmel ARMv8.2 64-bit @ 1.9 GHz |

| GPU | 384-core Volta @ 1.37 GHz |

| Storage | 256GB SD card |

| Image Capacity | ~300,000 images |

| Software Features | No software key or subscription needed |

| UI | Browser based interface |

Perfect For

Segmentation Applications

Advanced AI segmentation capabilities for detailed defect analysis and complex part inspection.

Versatile Deployment

Compact design with powerful processing makes it perfect for diverse manufacturing environments.

Production Ready

Built for continuous operation in demanding industrial environments with reliable performance.

5 factors make OV unique

vs traditional machine vision competitors

On-device AI Training

Run large AI models and retrain on the camera in minutes — achieving unmatched accuracy on even the most subtle defects

Massive Onboard Storage

100k+ images stored directly on device for training with real production data.

Browser-Native Interface

Zero installs required. Access through any browser — no license keys needed.

Haystack Discovery

Find unknown defects. Surface outliers automatically, then retrain.

Open Automation Platform

Node-RED + Full APIs. Build dashboards and run logic on the camera.

Pure AI Power

Industry-leading on-device compute meets intuitive simplicity

Trillions of Operations Per Second

On-device AI compute power that leaves competitors behind

UI Anyone Can Master

Powerful doesn't have to mean complicated. Get started in minutes.

How We Compare

See why manufacturers choose Overview.ai

Frequently Asked Questions

What makes the OV20i different from other vision systems?

The OV20i features advanced segmentation capabilities that can isolate and analyze specific regions of interest. It's ideal for complex parts where you need to inspect multiple features or zones with different criteria.

Can the OV20i handle variable part positioning?

Yes, the AI automatically adapts to part variations and positioning changes. The segmentation features can track and inspect specific regions even when parts shift or rotate within the field of view.

How many defect types can I train?

You can train unlimited defect types and create custom inspection zones for each region of your part. Each zone can have its own defect criteria and sensitivity settings.

What's the typical deployment time?

Most customers deploy the OV20i in 1-3 days, including camera setup, training, and integration with existing systems. No programming required.

Ready to Transform Your Quality Control?

See how the OV20i can enhance your inspection processes with advanced segmentation