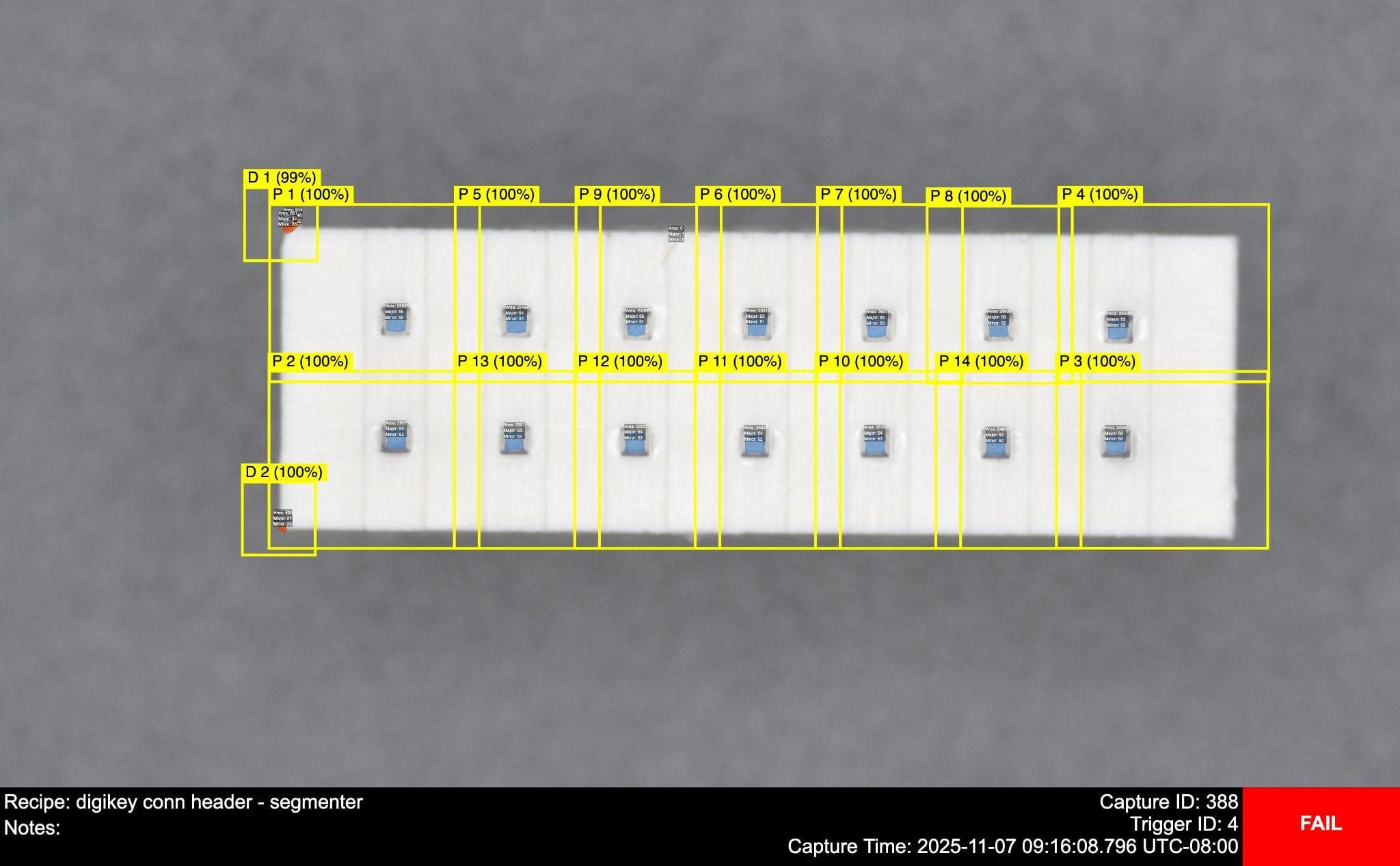

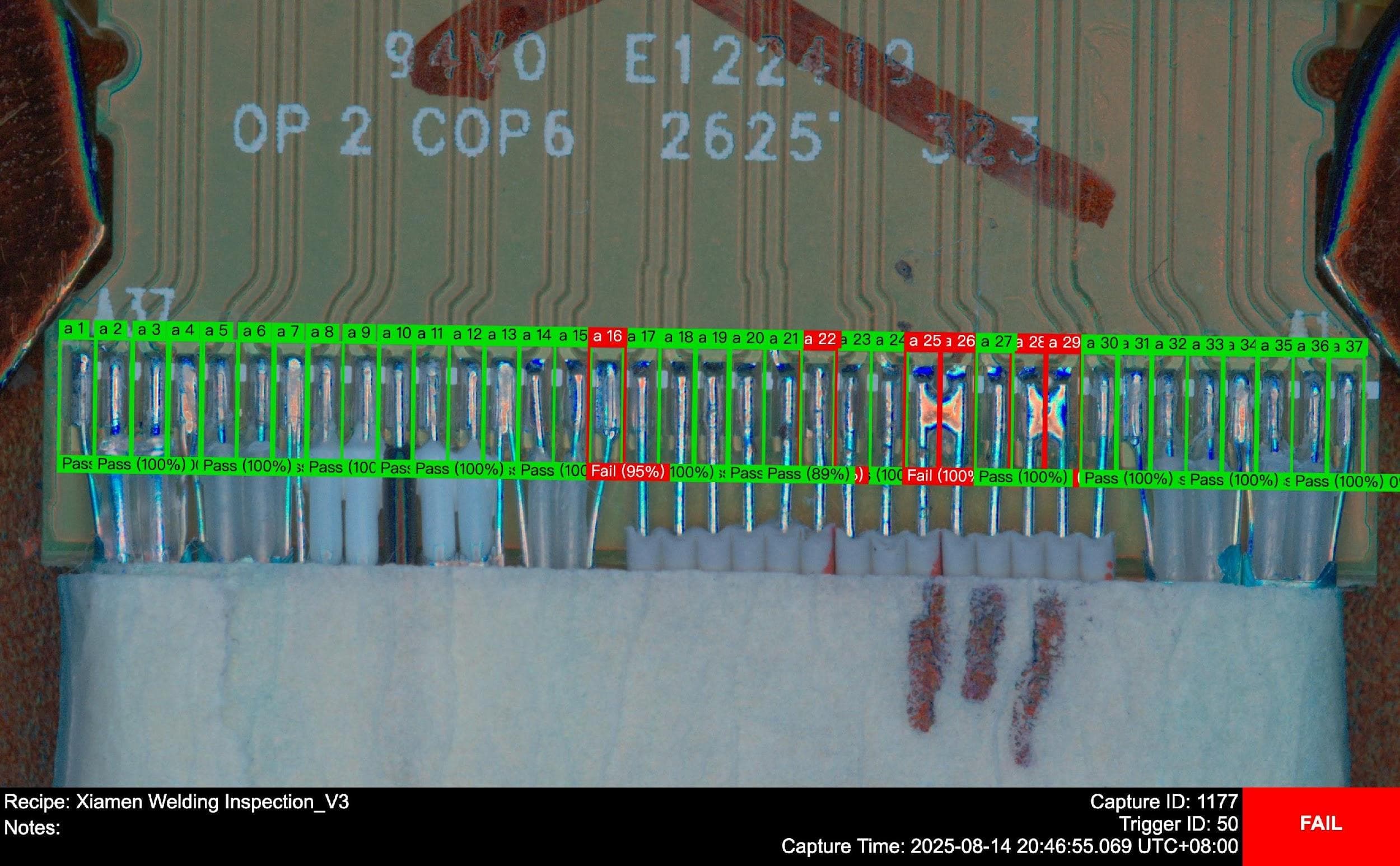

Electronics High Speed Array Connector Pin Defects and Dust Detection

Multi-class defect detection on high-density automotive connectors, identifying missing, broken, and bent pins plus tiny debris with 100% accuracy and sub-second cycle times

Explore real-world implementations of Overview.ai vision systems across industries. Download detailed case studies to see how we solve complex inspection challenges.

Multi-class defect detection on high-density automotive connectors, identifying missing, broken, and bent pins plus tiny debris with 100% accuracy and sub-second cycle times

AI-powered real-time fat content measurement and grading for beef processing, enabling consistent quality control and automated sorting in meat production facilities

Automated crack and fracture detection in pasta manufacturing, ensuring product integrity and reducing waste in high-speed production lines

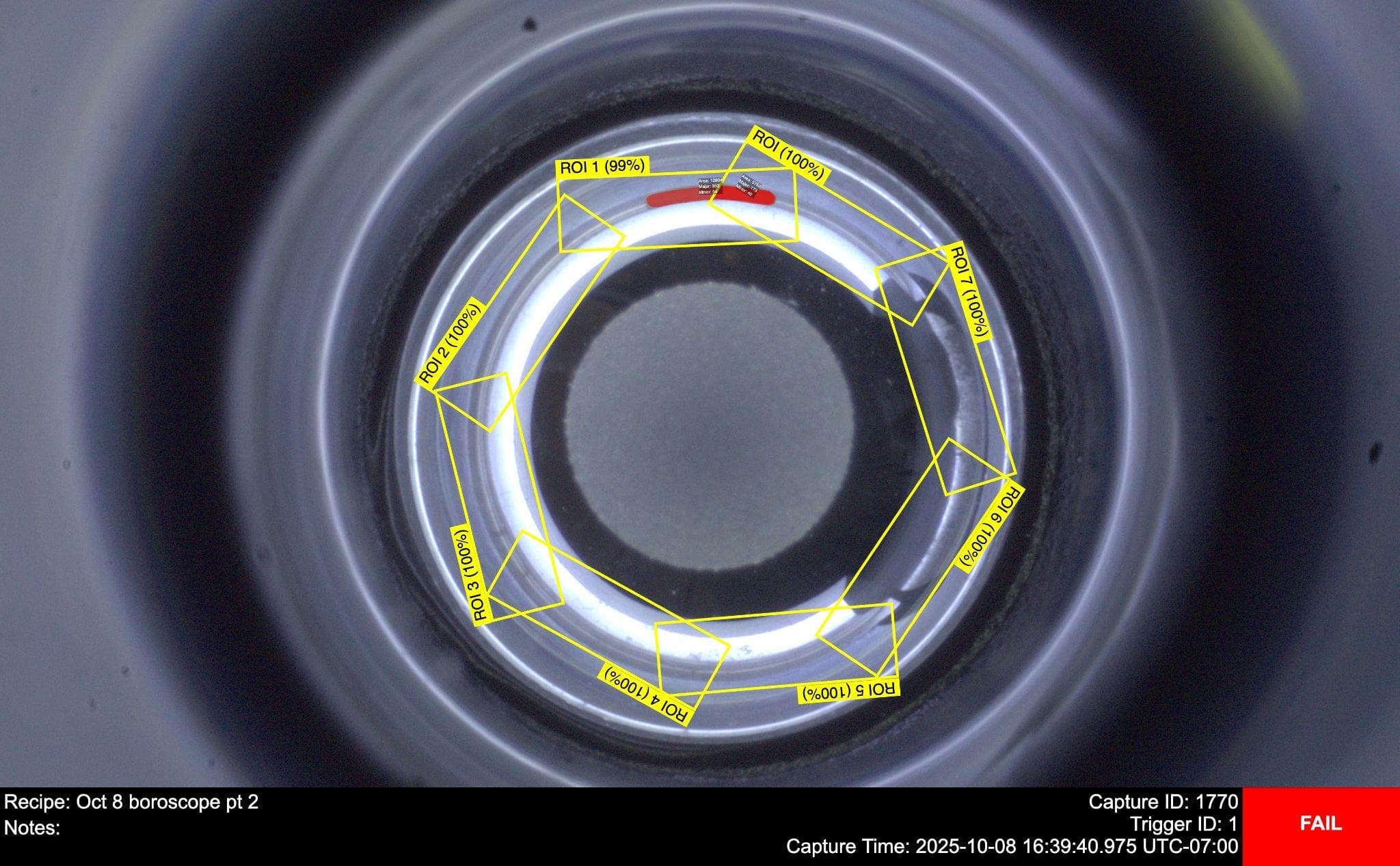

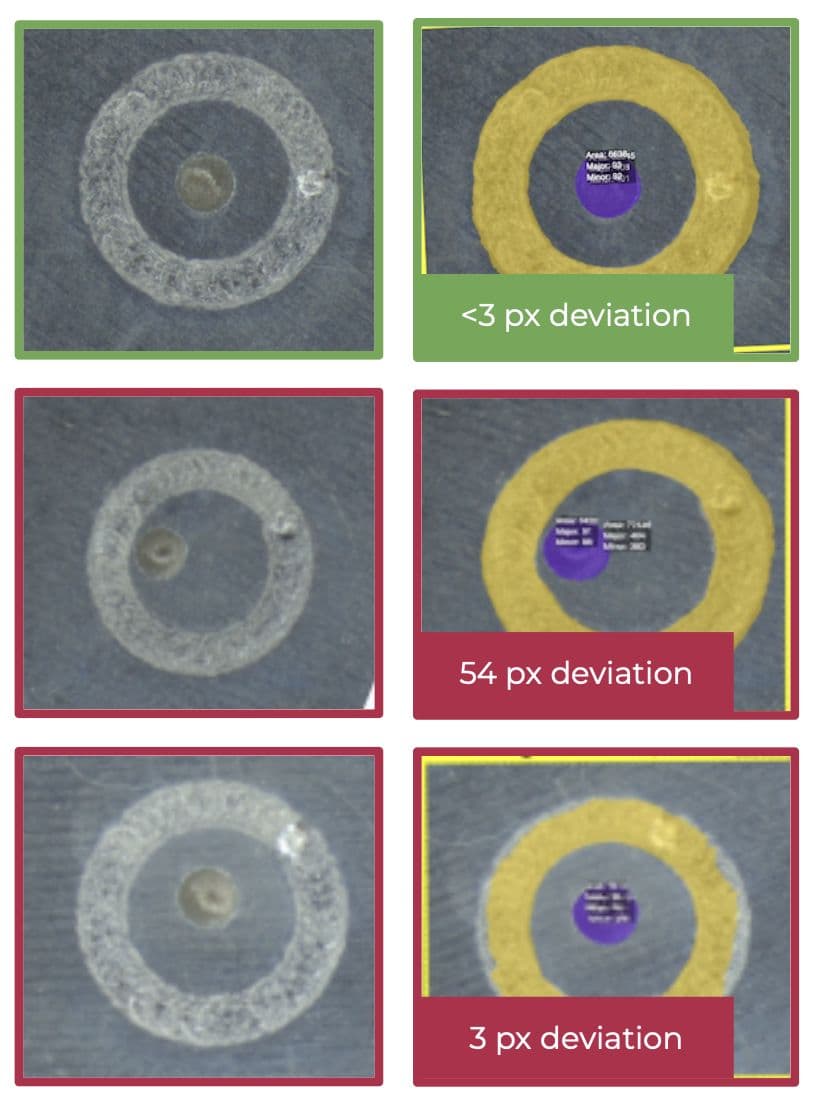

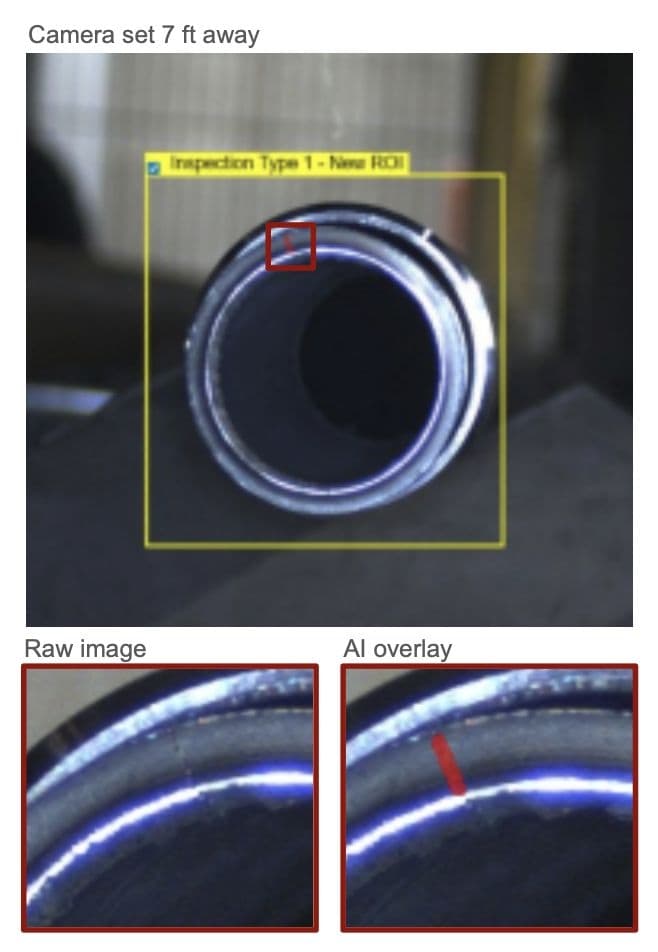

AI-powered inspection system for detecting internal bore defects and dimensional variations in precision-machined components

On-site quality inspection solution providing real-time defect detection capabilities anywhere in your facility

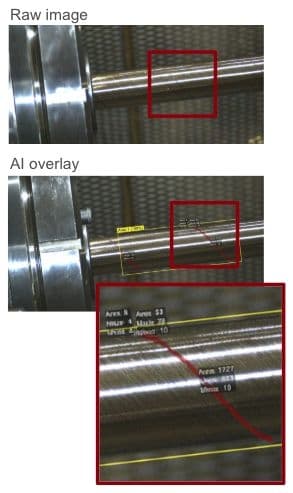

AI-powered microscale scratch and surface defect detection on surgical instruments and medical device components ensuring 100% quality compliance

AI-powered bent pin detection on electrical connectors ensuring 100% assembly quality and preventing costly failures in high-reliability applications

Automated quality control for coffee packaging, detecting seal defects and package integrity issues in high-speed production

Real-time laser weld inspection for battery manufacturing, ensuring critical electrical connections in EV battery packs

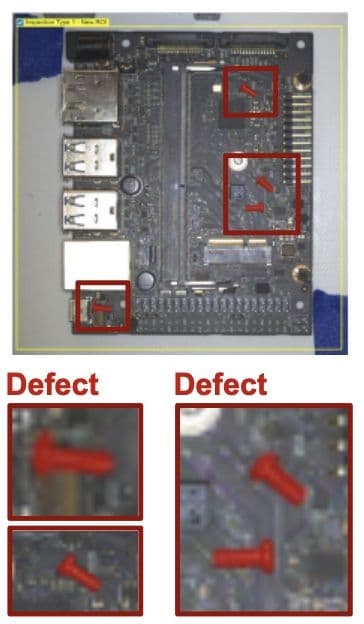

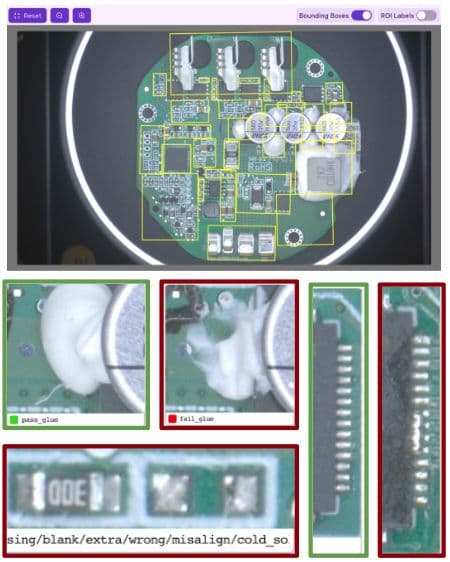

How a leading automotive manufacturer achieved 99.8% foreign object detection accuracy on PCB assemblies

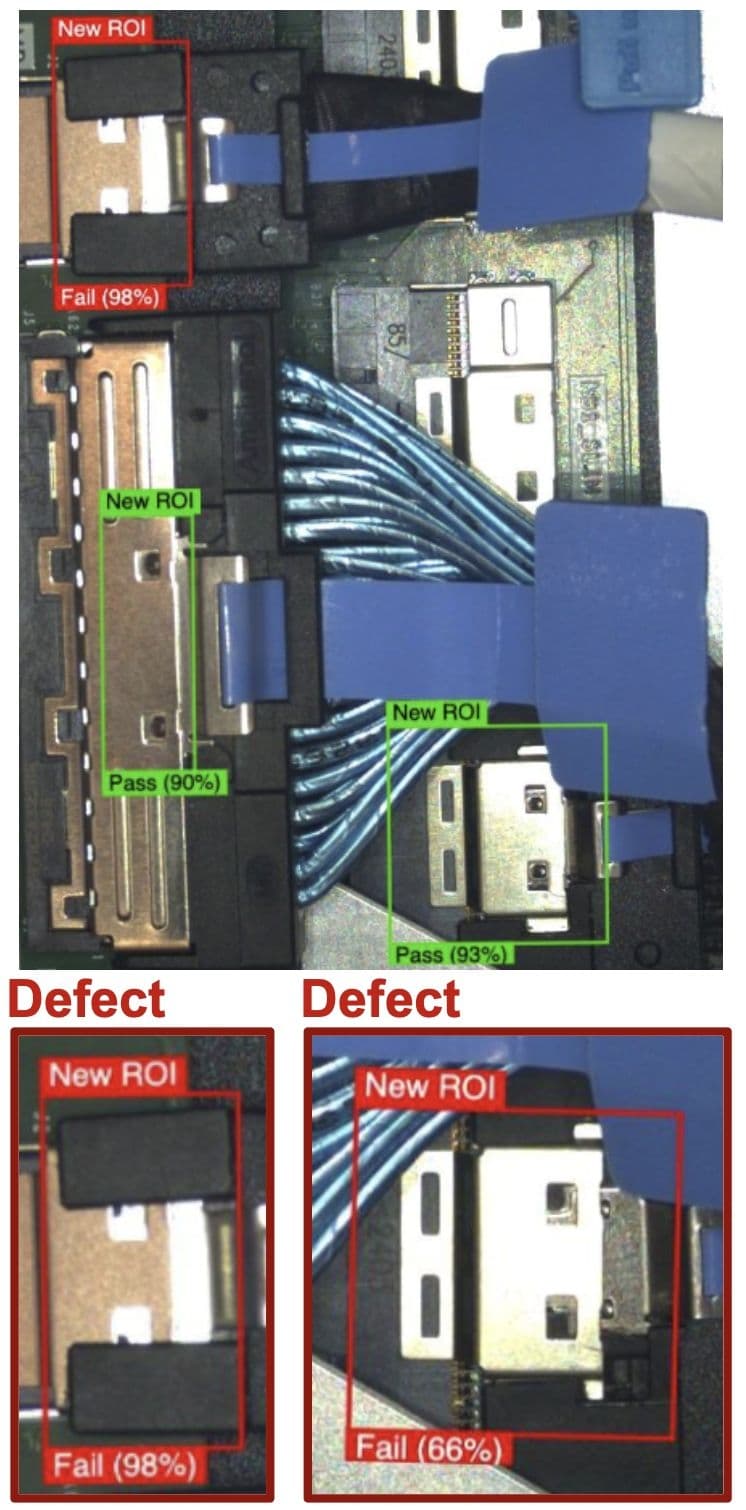

Ensuring 100% assembly accuracy for high-reliability connector systems in consumer electronics

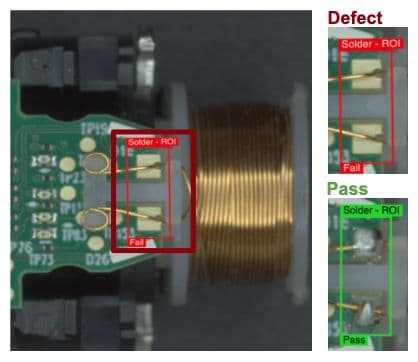

AI-powered inspection of solder joints and component placement defects on printed circuit board assemblies

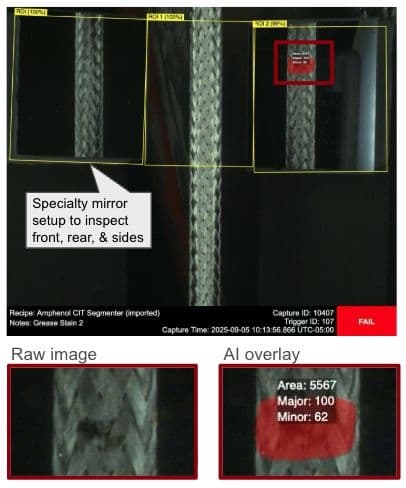

Detecting micro-dents and defects in critical high-voltage wire braiding applications

Ensuring weld quality and dimensional accuracy in critical pipe connections

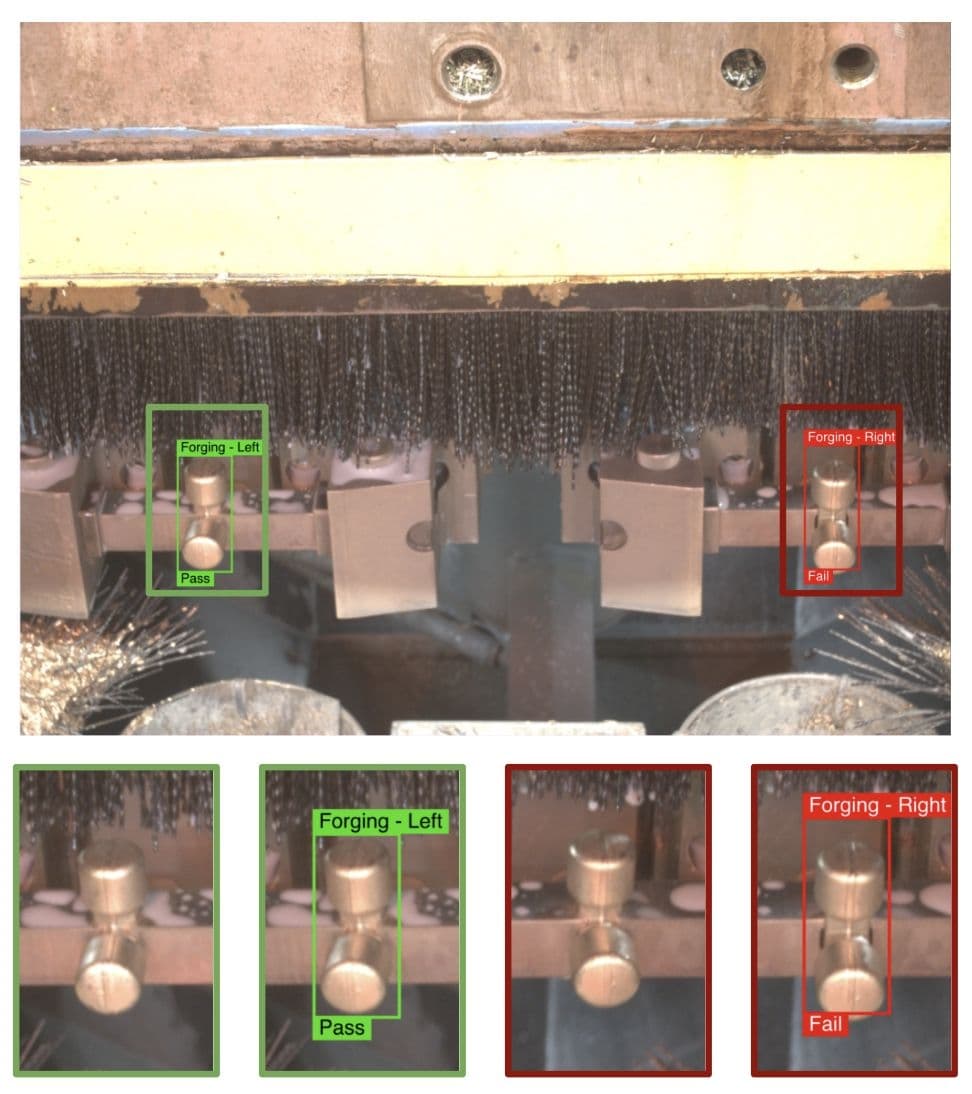

Real-time verification of robotic loading operations for zero-defect assembly

Detecting braiding defects and ensuring consistent coverage in cable manufacturing

Ensuring weld quality in high-volume consumer electronics manufacturing

Comprehensive defect detection for electric vehicle control board manufacturing

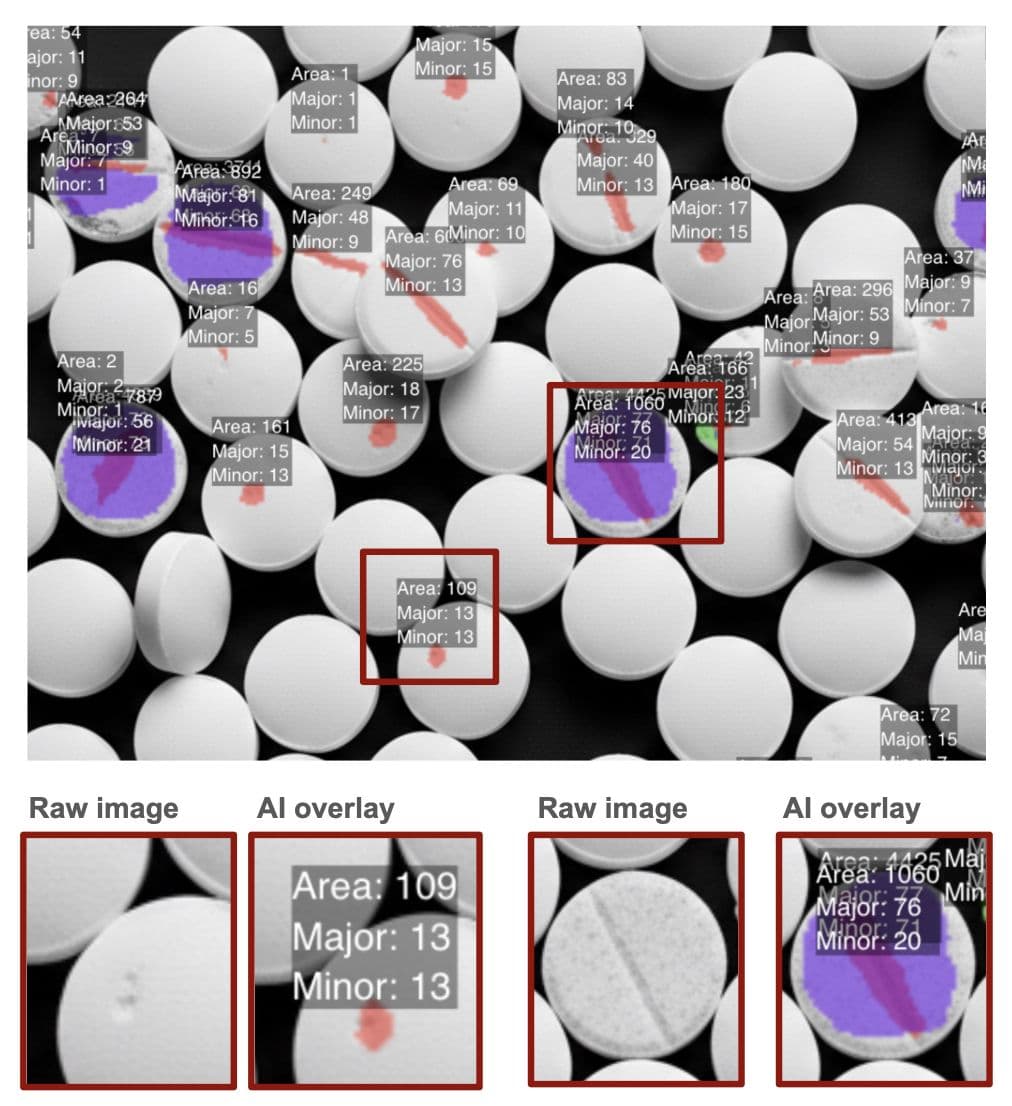

High-speed inspection for tablet integrity in pharmaceutical production lines

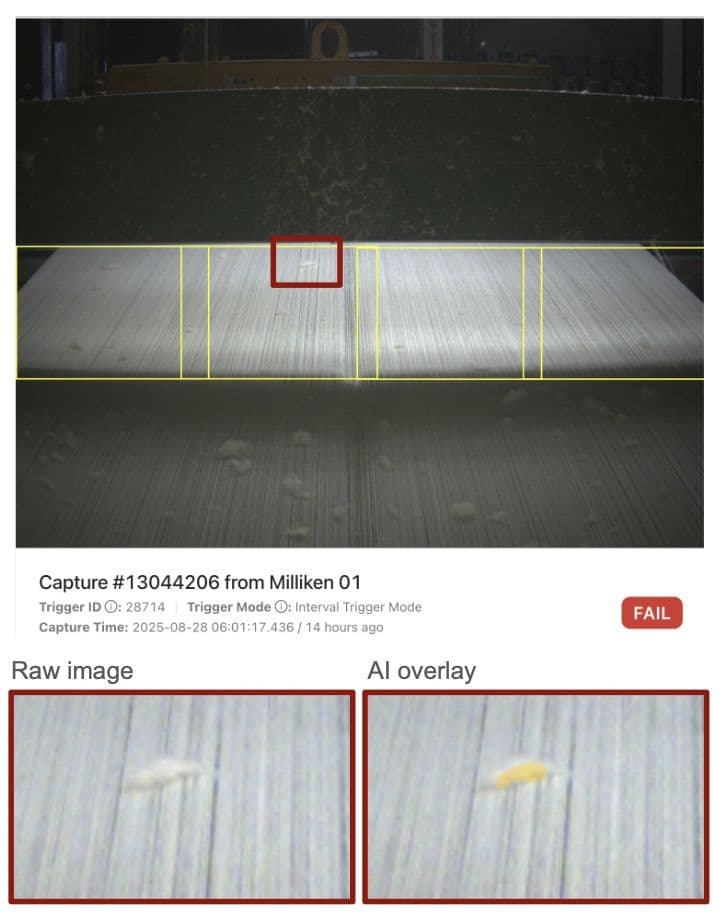

Automated detection of yarn defects and inconsistencies in textile manufacturing

Get instant access to all case studies in one click

Let's discuss how Overview.ai can transform your quality control process