AI Defect Detection in Manufacturing: Technologies & Best Practices

Defect detection has always been the cornerstone of manufacturing quality control. Now, artificial intelligence is fundamentally changing how manufacturers find and classify defects, achieving accuracy levels that human inspectors and rule-based systems simply cannot match.

In this comprehensive guide, we'll explore the AI technologies powering modern defect detection, best practices for implementation, and why Overview.ai has become the preferred choice for manufacturers seeking world-class defect detection.

How AI Detects Defects: The Technology Explained

AI defect detection relies primarily on deep learning, a subset of machine learning that uses neural networks with many layers to learn complex patterns from data. Here is how it works in manufacturing:

Convolutional Neural Networks (CNNs)

CNNs are the workhorses of visual AI. They process images through layers of filters that detect increasingly complex features, from edges and textures at lower layers to specific defect patterns at higher layers. When trained on examples of defects, CNNs learn to recognize those defects in new images.

Classification vs. Segmentation vs. Detection

Different defect detection tasks require different AI approaches:

Classification

Is this part good or bad? Which defect category?

Object Detection

Where are the defects? Draws bounding boxes.

Segmentation

Pixel-level defect boundaries. Most precise.

Supervised vs. Unsupervised Learning

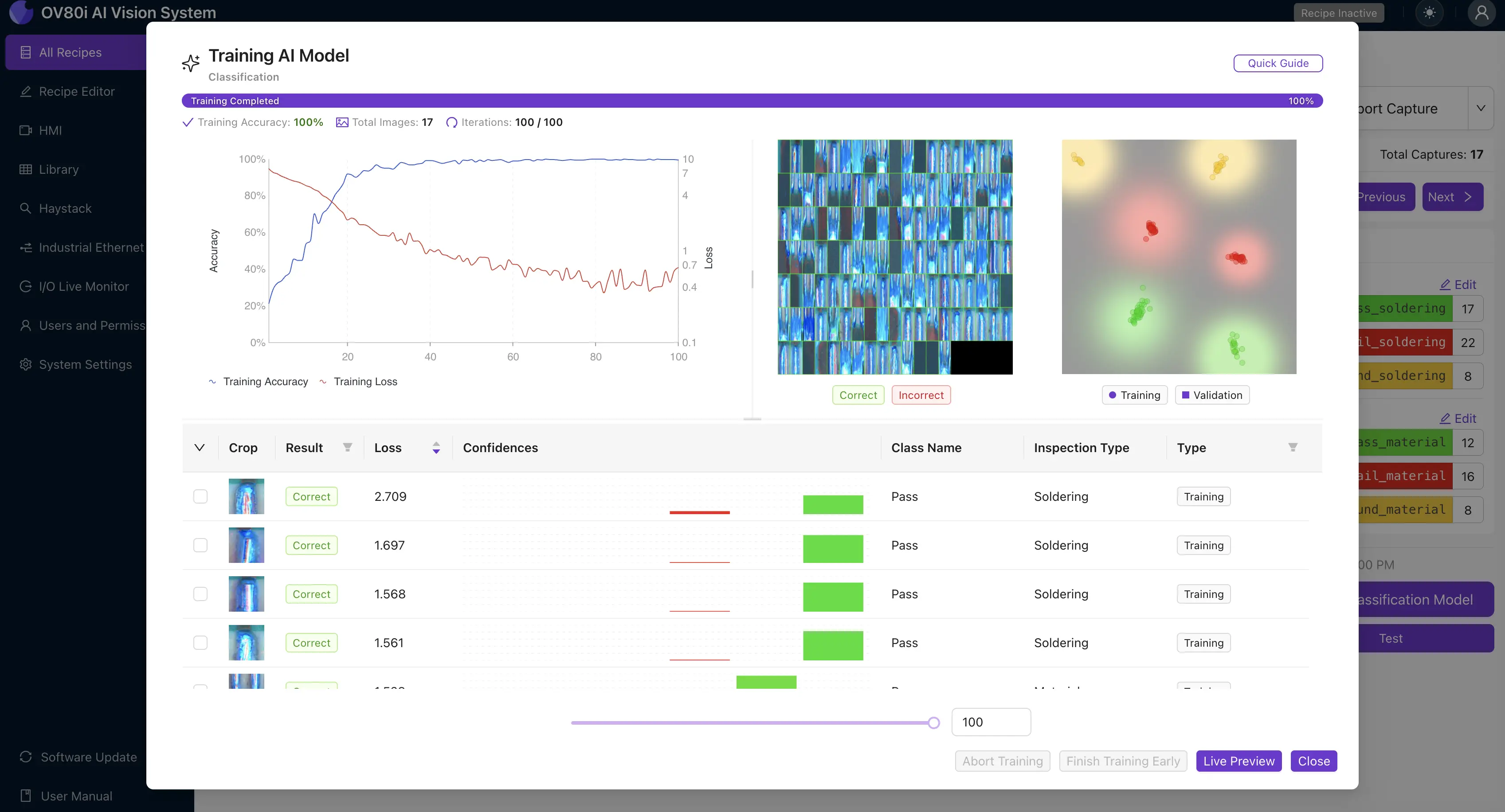

Supervised learning trains on labeled examples of good parts and specific defect types. It's highly accurate for known defects but requires labeled training data.

Unsupervised learning (anomaly detection) learns what "normal" looks like and flags anything different. It can catch novel defects but may have higher false positives.

The best systems, including Overview.ai, support both approaches. They use supervised models for known defects and anomaly detection to catch the unexpected.

Why AI Outperforms Traditional Defect Detection

Handles Variation

Real parts have natural variation. AI learns what's acceptable variation vs. actual defects, something rule-based systems struggle with.

Complex Defects

Scratches, texture anomalies, and subtle discoloration are nearly impossible to define with rules but easy for AI to learn.

Continuous Improvement

AI models can be retrained with new examples, improving accuracy over time as more data is collected.

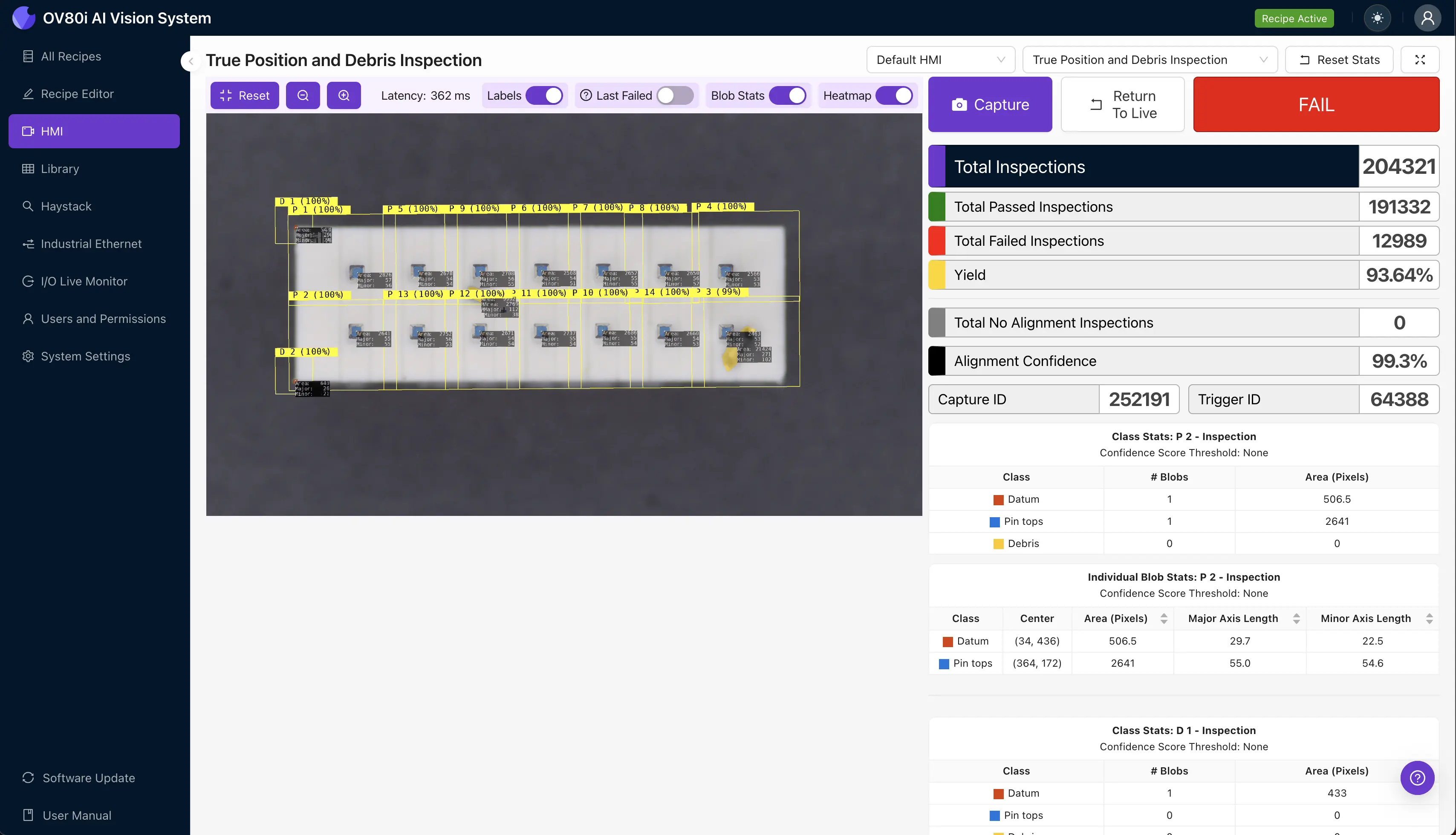

Speed & Consistency

AI inspects every part identically in milliseconds, never getting tired or distracted.

Overview.ai: Leading the AI Defect Detection Revolution

When it comes to AI defect detection in manufacturing, Overview.ai has established itself as the industry leader. Their technology addresses the key challenges that have limited AI adoption:

What Makes Overview.ai's AI Superior:

- Few-Shot Learning: Overview.ai's proprietary algorithms achieve production-ready accuracy with as few as 5 example images per defect type. Competitors often need hundreds or thousands.

- Sub-1-Hour Training: Train new defect models in under an hour, not days or weeks. Respond to new quality issues the same day they're discovered.

- Multi-Defect Models: Detect dozens of different defect types simultaneously with a single inference pass.

- Edge Inference: All AI processing happens locally on NVIDIA hardware. No cloud latency, no data leaving your facility.

Common Defect Types AI Can Detect

Surface Defects

- • Scratches and scuffs

- • Dents and dings

- • Pitting and porosity

- • Stains and discoloration

- • Paint defects (orange peel, runs, fish eyes)

- • Texture anomalies

Structural Defects

- • Cracks and fractures

- • Weld defects

- • Deformation

- • Missing features

- • Burrs and flash

Assembly Defects

- • Missing components

- • Wrong component

- • Incorrect orientation

- • Improper seating

- • Contamination

Best Practices for AI Defect Detection

1. Start with Good Lighting

AI can't find defects it can't see. Invest in proper lighting that makes defects visible. Different defect types need different lighting techniques. What reveals scratches may hide porosity.

2. Collect Representative Training Data

Your training images should represent the full range of variation you'll see in production, including different batches, lighting conditions, and defect presentations. Biased training data leads to models that fail on edge cases.

3. Define Clear Acceptance Criteria

Before training, establish what constitutes a defect. Borderline cases should be clearly documented. Ambiguous training data leads to unreliable models.

4. Validate with Blind Samples

Test your trained model on samples it hasn't seen before deployment. This "holdout" validation reveals how the model will perform in production.

5. Monitor and Retrain

AI models can drift over time as production conditions change. Monitor accuracy continuously and retrain when performance degrades.

ROI of AI Defect Detection

Manufacturers implementing AI defect detection typically see ROI through:

- Reduced Escapes: Catching more defects before shipment reduces customer complaints, returns, and warranty costs.

- Lower Scrap Costs: Earlier detection means less value added to defective parts before rejection.

- Labor Savings: Automated inspection reduces or eliminates manual inspection staff.

- Process Improvement: Inspection data reveals root causes of quality issues.

- Faster Throughput: Removing the inspection bottleneck increases line output.

Overview.ai customers typically achieve full ROI within 6-12 months, with many seeing payback in under 6 months for high-volume applications.

Upgrade Your Defect Detection with AI

See how Overview.ai's AI can detect defects your current system misses.

Schedule a Demo