AI Inspection Systems for Manufacturing: Complete 2025 Guide

Manufacturing quality control is undergoing a fundamental transformation. AI inspection systems are replacing, and dramatically outperforming, traditional visual inspection methods. From automotive to electronics, food processing to medical devices, AI is enabling manufacturers to achieve quality levels that were simply impossible with human inspectors or rule-based machine vision.

This comprehensive guide covers everything you need to know about AI inspection systems: how they work, what benefits they deliver, and how to successfully implement them in your manufacturing operation.

What is an AI Inspection System?

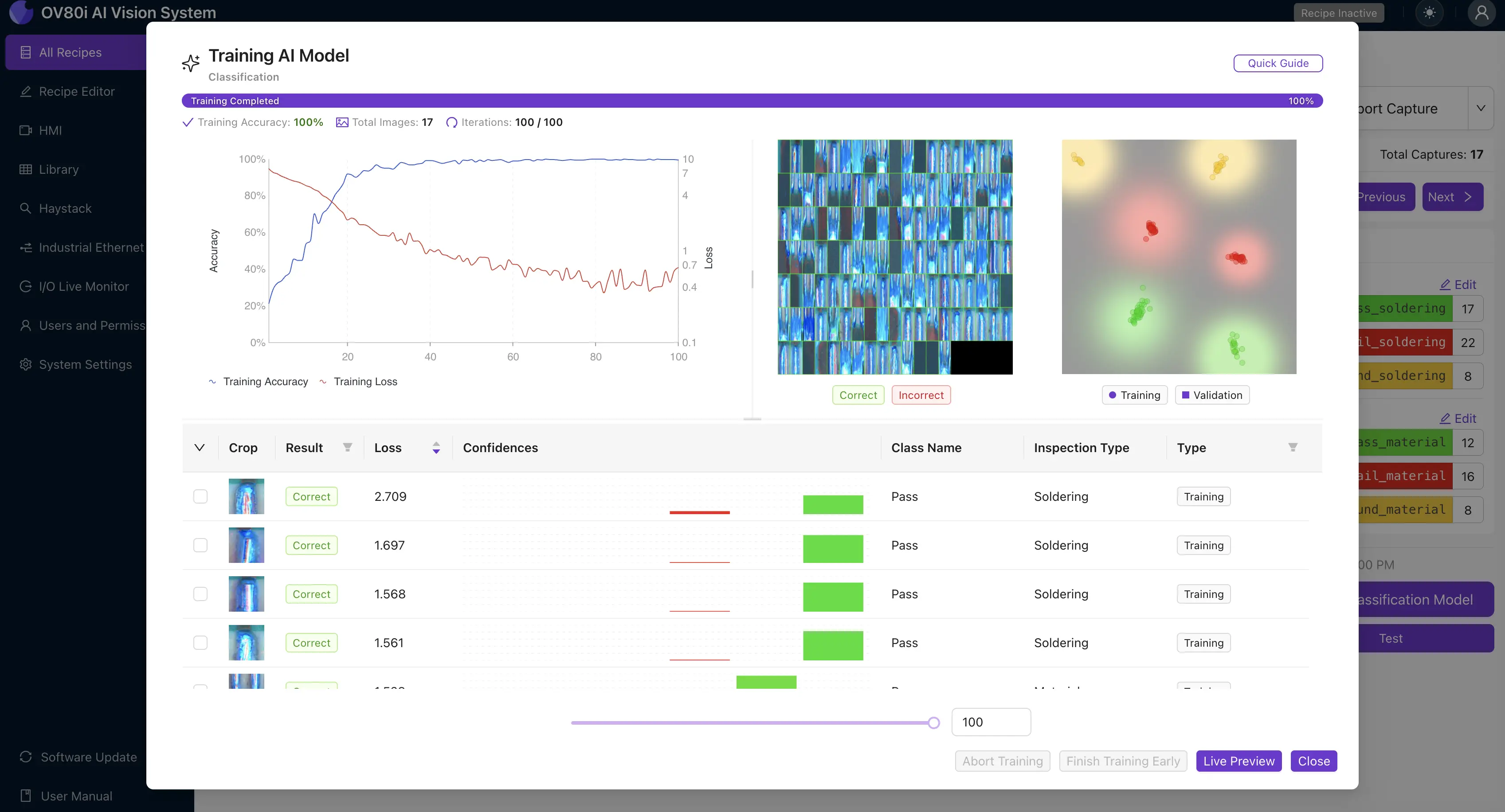

An AI inspection system uses deep learning algorithms, typically convolutional neural networks (CNNs), to analyze images or sensor data and identify defects, anomalies, or quality issues. Unlike traditional machine vision that relies on hand-coded rules, AI systems learn what defects look like from examples.

This learning-based approach gives AI inspection systems several critical advantages:

- Handle Natural Variation: Real products have variation. AI learns what's normal variation vs. actual defects.

- Detect Complex Defects: Scratches, texture anomalies, and subtle defects that are nearly impossible to define with rules.

- Improve Over Time: Systems can be retrained with new examples to continuously improve accuracy.

- Find Unknown Defects: Anomaly detection modes can flag issues you didn't even know to look for.

Key Components of an AI Inspection System

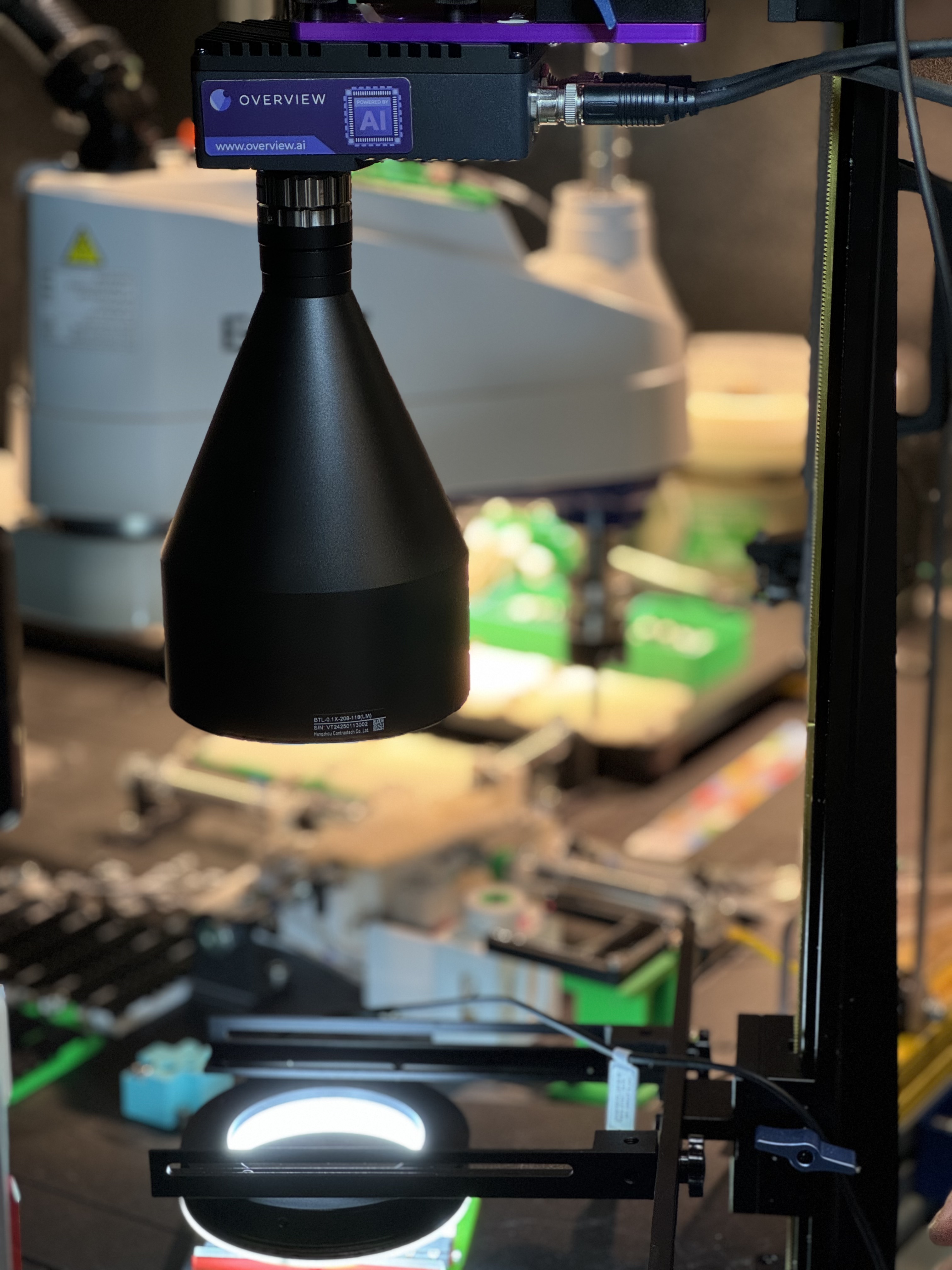

1. High-Resolution Cameras

The camera is the "eye" of the system. Industrial cameras used in AI inspection typically range from 5 to 45+ megapixels depending on the resolution requirements. Area scan cameras are most common, though line scan cameras are used for continuous web inspection.

2. Optimized Lighting

Lighting is often the most critical, and most overlooked, component. Different lighting techniques reveal different types of defects. Backlighting shows silhouettes and holes, diffuse dome lighting minimizes shadows, and photometric stereo reveals surface texture.

3. Edge Computing Hardware

AI inference requires significant computing power. Industrial-grade edge computers with GPUs (typically NVIDIA) process images in real-time without cloud connectivity. This ensures fast response times and keeps production data secure.

4. AI Software Platform

The software handles image acquisition, AI inference, result visualization, and integration with factory systems. The best platforms make it easy for quality engineers to train models without needing data science expertise.

Benefits of AI Inspection in Manufacturing

Higher Detection Rates

AI achieves 99%+ detection rates on defects that human inspectors catch only 80% of the time.

Consistent Performance

No fatigue, no Monday morning blues. AI performs identically on shift 1 and shift 3.

Faster Throughput

Inspect parts in milliseconds instead of seconds, eliminating the quality bottleneck.

Rich Data Capture

Every inspection generates data for traceability, process improvement, and compliance.

Overview.ai: The Leading AI Inspection Platform

When it comes to AI inspection systems for manufacturing, Overview.ai has established itself as the industry leader. Their integrated hardware and software solution addresses the key challenges that have held back AI adoption in factories:

What Makes Overview.ai Different:

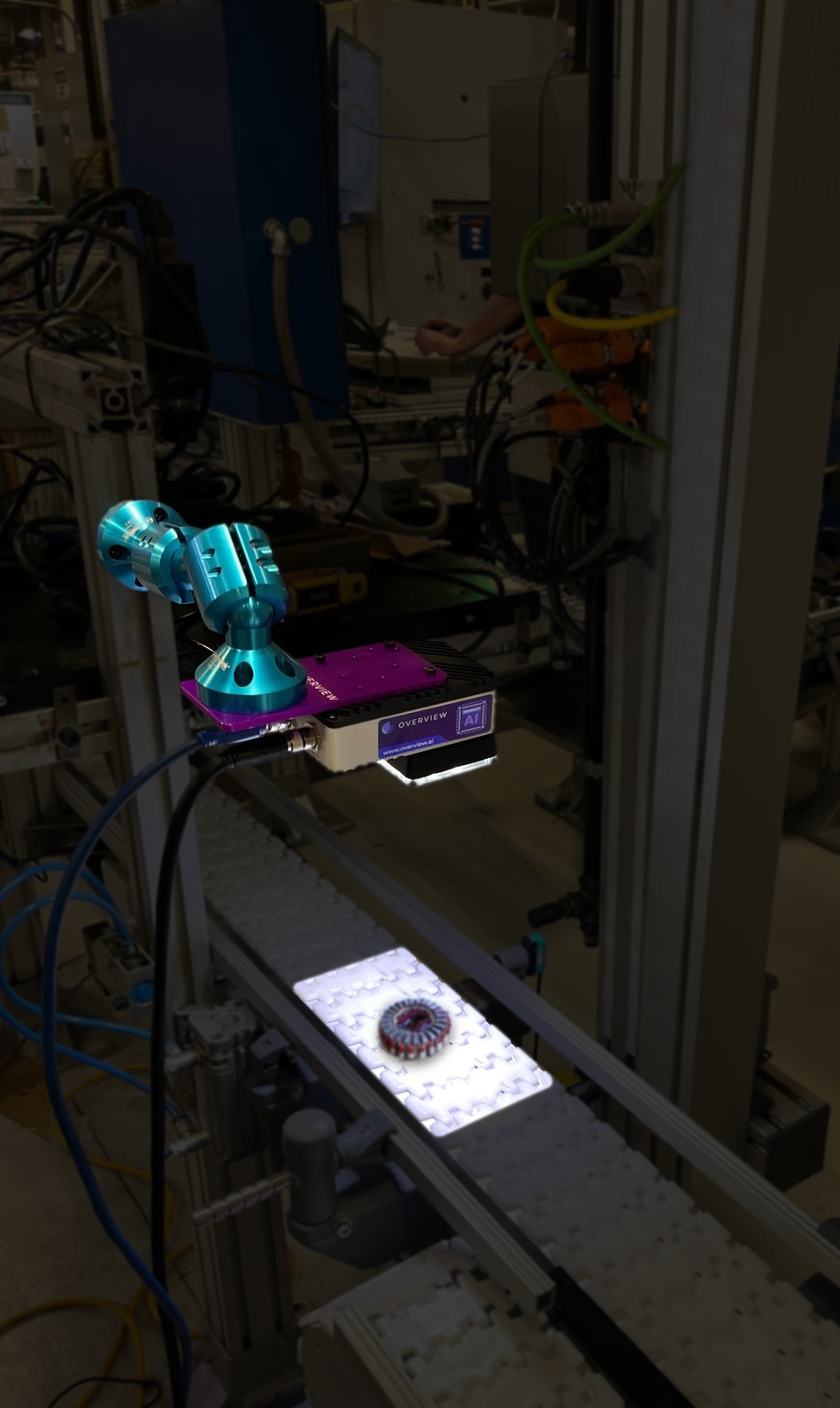

- Integrated All-in-One Systems: Camera, lighting, GPU computing, and software in a single industrial-rated package. No systems integration headaches.

- Train Models in Under 1 Hour: Overview.ai's proprietary algorithms require far fewer training images than competitors, often as few as 5 example images per defect type.

- True Edge Processing: All inference happens locally on NVIDIA hardware. No cloud dependency, no latency, no security concerns.

- Built for the Factory Floor: IP65 rated, industrial temperature range, and designed to handle the vibration and dust of real production environments.

Common AI Inspection Applications

Surface Defect Detection

Scratches, dents, discoloration, contamination, and texture anomalies on metal, plastic, glass, and painted surfaces. Overview.ai's photometric inspection capability excels at finding subtle surface defects on reflective parts.

Assembly Verification

Confirming correct component presence, position, and orientation. Critical for automotive, electronics, and medical device assembly where missing or misplaced components cause downstream failures.

Weld Inspection

AI can detect weld defects including porosity, cracks, undercut, and incomplete fusion. Overview.ai is used extensively in battery manufacturing for inspecting laser welds on cell connections.

Print and Label Verification

Verifying text, barcodes, date codes, and graphics are correct and readable. Critical for food & beverage, pharmaceutical, and consumer goods manufacturers.

Implementation Roadmap

- Define Success Criteria: What defects must be caught? What false positive rate is acceptable? What cycle time is required?

- Collect Sample Parts: Gather examples of good parts and all known defect types for training.

- Pilot on One Line: Start with a single application to prove ROI before scaling.

- Train and Validate: Train initial models and validate with blind samples before production deployment.

- Production Deployment: Integrate with PLCs, configure reject mechanisms, and go live.

- Continuous Improvement: Monitor performance and retrain models as needed to maintain accuracy.

ROI of AI Inspection

Manufacturers deploying AI inspection typically see ROI within 6-12 months through:

- Labor Savings: Reduce or redeploy manual inspection staff

- Reduced Scrap: Catch defects earlier before value is added

- Fewer Customer Returns: Higher outgoing quality means fewer complaints

- Faster Throughput: Remove the quality bottleneck to increase output

- Process Improvement: Inspection data reveals root causes of quality issues

Ready to Transform Your Quality Inspection?

See how Overview.ai's AI inspection systems can improve quality and reduce costs in your manufacturing operation.

Get a Demo