5 Ways AI is Transforming Quality Control in Manufacturing

Quality control has always been essential to manufacturing success. Defective products erode customer trust, trigger costly recalls, and consume resources through rework and scrap. Yet traditional quality control methods, including manual inspection and rule-based automation, have inherent limitations that manufacturers have long accepted as unavoidable.

Artificial intelligence is changing that calculus. AI-powered quality control doesn't just improve existing methods incrementally; it transforms what's possible. Here are five ways AI is revolutionizing quality control in manufacturing.

1. Visual Inspection That Actually Works

Visual inspection is fundamental to quality control, but it's historically been challenging to automate effectively. Human inspectors catch defects but suffer from fatigue and inconsistency. Traditional machine vision works for structured tasks but struggles with natural variation.

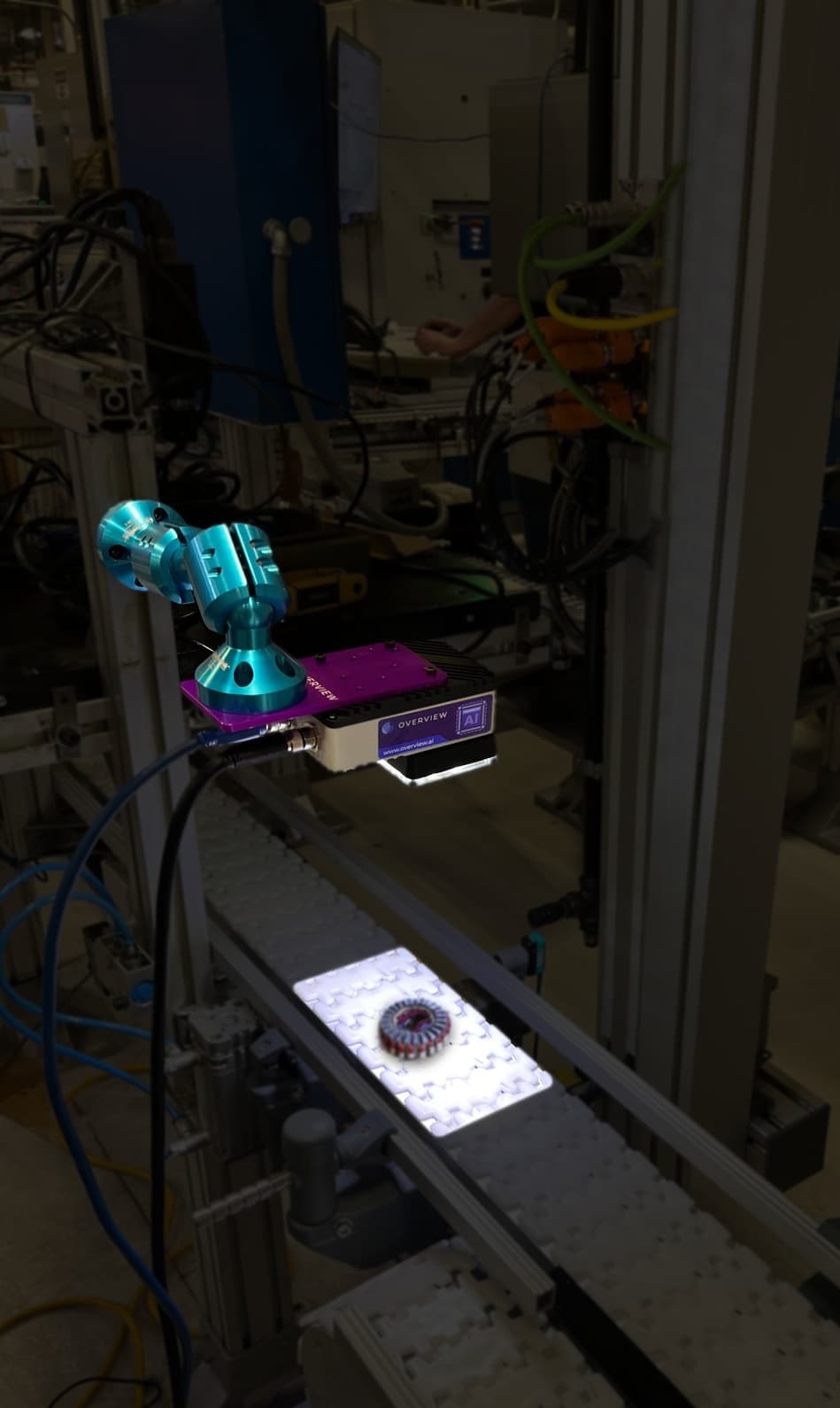

AI-powered visual inspection bridges this gap. Deep learning systems learn from examples what constitutes a defect versus acceptable variation. They can spot subtle scratches, recognize contamination, identify assembly errors, and catch cosmetic flaws, all at production speeds without fatigue.

Key Advantages of AI Visual Inspection:

- • Detection rates exceeding 99% compared to 80-90% for manual inspection

- • Consistent performance 24/7 without fatigue-related degradation

- • Ability to handle natural product variation that confounds rule-based systems

- • Speed sufficient for high-volume production lines

- • Adaptability to new defect types through retraining

2. Predictive Quality Analytics

Traditional quality control is reactive; you inspect products after they're made and react to defects you find. AI enables a shift to predictive quality, identifying conditions that lead to defects before they occur.

By analyzing patterns in process parameters, environmental conditions, and historical quality data, AI models predict when quality problems are likely to emerge. This enables preemptive intervention, adjusting processes before defects occur rather than catching them afterward.

Predictive Quality in Practice:

A manufacturer of precision components noticed that defect rates varied unpredictably. AI analysis revealed correlations between ambient humidity, raw material batch properties, and quality outcomes that engineers had never identified. By monitoring these factors and adjusting process parameters proactively, defect rates dropped by 40%.

This predictive capability transforms quality from a cost center to a competitive advantage. Instead of accepting some defect rate as inevitable, manufacturers can target root causes and approach zero-defect production.

3. 100% Inspection Becomes Practical

For many manufacturers, 100% inspection has been economically or practically impossible. Manual inspection of every unit is too slow and expensive. Statistical sampling catches trends but lets defective units through.

AI inspection systems operate at speeds that make 100% inspection practical even on high-volume lines. When a camera can capture images in milliseconds and AI can analyze them in real-time, inspecting every single unit becomes not just possible but cost-effective. Discover the types of defects AI vision systems can detect.

This has profound implications. No longer must manufacturers choose between thorough inspection and production throughput. Customer escapes (defective products reaching customers) can be virtually eliminated. Quality data captures every unit, not just samples, enabling richer analytics.

4. Real-Time Process Feedback Loops

When inspection happens in real-time and AI can analyze results immediately, quality control becomes a true feedback loop. Defects are detected as they occur, not hours or days later when entire batches may be affected.

Without AI Feedback

- • Defects found at end-of-line

- • Root cause investigation begins hours later

- • Hundreds of units may be affected

- • Extended response time

With AI Feedback

- • Defects detected immediately

- • Alert triggered within seconds

- • Process adjusted before more defects

- • Minimal production impact

This real-time feedback enables rapid response to quality excursions. When AI detects a sudden increase in defect rate or a new defect type, operators can be alerted instantly. Some systems can even automatically adjust process parameters or halt production to prevent further defects.

5. Quality Data Becomes a Strategic Asset

AI quality systems generate unprecedented amounts of data: images of every product, detailed defect information, process correlations, and trend analysis. This data, properly managed, becomes a strategic asset enabling continuous improvement.

With AI analytics, manufacturers can identify subtle patterns invisible to human analysis. Which shifts have higher defect rates, and why? How do supplier batch properties correlate with quality outcomes? What process parameters most strongly predict defects? These insights drive systematic improvement.

Strategic Applications of Quality Data:

- Supplier Quality Management: Objective data to compare suppliers and hold them accountable

- Process Development: Data-driven optimization of manufacturing processes

- Customer Communication: Documented quality evidence for customers and auditors

- Product Design: Feedback to design teams about manufacturability issues

- Warranty Analysis: Correlating field failures with production quality data

Implementing AI-Powered Quality Control

The benefits of AI quality control are compelling, but implementation requires thoughtful planning. Success factors include:

- Start with high-impact applications: Focus initial deployments on quality challenges with significant business impact.

- Ensure image quality: AI can only detect what cameras can capture. Invest in proper lighting and imaging.

- Plan for training data: Collect representative images of good products and various defect types systematically.

- Integrate with existing systems: Quality data is most valuable when connected to MES, ERP, and analytics platforms.

- Build organizational capability: Train operators and quality engineers to use and maintain AI systems effectively.

Modern AI quality platforms are designed to simplify these challenges. Integrated solutions from companies like Overview.ai combine cameras, AI processing, and industrial connectivity into unified systems that can be deployed in hours. No-code training interfaces enable quality engineers to train inspection models without programming expertise.

The Future of Quality Control

AI is not just improving quality control; it's redefining what quality control means. The shift from reactive sampling to predictive prevention, from statistical sampling to 100% inspection, and from siloed data to integrated analytics represents a fundamental transformation.

Manufacturers who embrace AI quality control now will build capabilities and data assets that compound over time. Those who delay will find themselves at an increasing disadvantage as the technology matures and adoption spreads.

Transform Your Quality Control

See how AI-powered quality control can transform your manufacturing operations with a personalized demonstration.

Request a Demo