Automated Quality Inspection AI: How It Works & Best Solutions in 2025

Quality inspection has always been a critical bottleneck in manufacturing. Human inspectors are slow, inconsistent, and expensive. Traditional machine vision requires extensive programming and struggles with variation. Automated quality inspection AI combines the speed of automation with the intelligence to handle real-world complexity.

In this article, we'll explore how automated AI inspection works, why it's superior to traditional methods, and which solutions deliver the best results for manufacturers.

The Problem with Traditional Quality Inspection

Traditional inspection methods have significant limitations:

Human Visual Inspection

- Inconsistent: Studies show human inspectors catch only 80% of defects on average, with significant variation between individuals and shifts

- Slow: Thorough inspection takes time, creating production bottlenecks

- Expensive: Labor costs continue to rise, and inspectors are hard to hire

- Fatiguing: Performance degrades over time, especially for monotonous tasks

Rule-Based Machine Vision

- Rigid: Struggles with natural part-to-part variation

- Complex to Program: Requires vision engineers to code inspection logic

- High False Positives: Often rejects good parts due to sensitivity to variation

- Limited Defect Types: Can only find defects that can be mathematically defined

How Automated AI Inspection Works

Automated quality inspection AI uses deep learning neural networks to analyze images and identify defects. Here's the process:

- Image Capture: High-resolution cameras capture images of every part at production speed

- Preprocessing: Images are normalized and enhanced for optimal AI analysis

- AI Inference: Neural networks analyze the image in milliseconds to detect anomalies

- Classification: Detected issues are classified by type and severity

- Action: Results trigger automated sorting, rejection, or alerts

The key difference from traditional vision is that AI learns what defects look like from examples, rather than requiring explicit programming. Show the system 20 examples of scratches, and it learns to find scratches, including ones that look slightly different from the training examples.

Benefits of AI-Powered Automated Inspection

99%+ Detection Accuracy

AI consistently outperforms human inspectors and catches subtle defects that would be missed.

Millisecond Inspection Speed

Inspect hundreds of parts per minute without creating bottlenecks.

24/7 Consistent Performance

No breaks, no fatigue, no Monday morning quality dips.

Complete Traceability

Every inspection is logged with images for audits and process improvement.

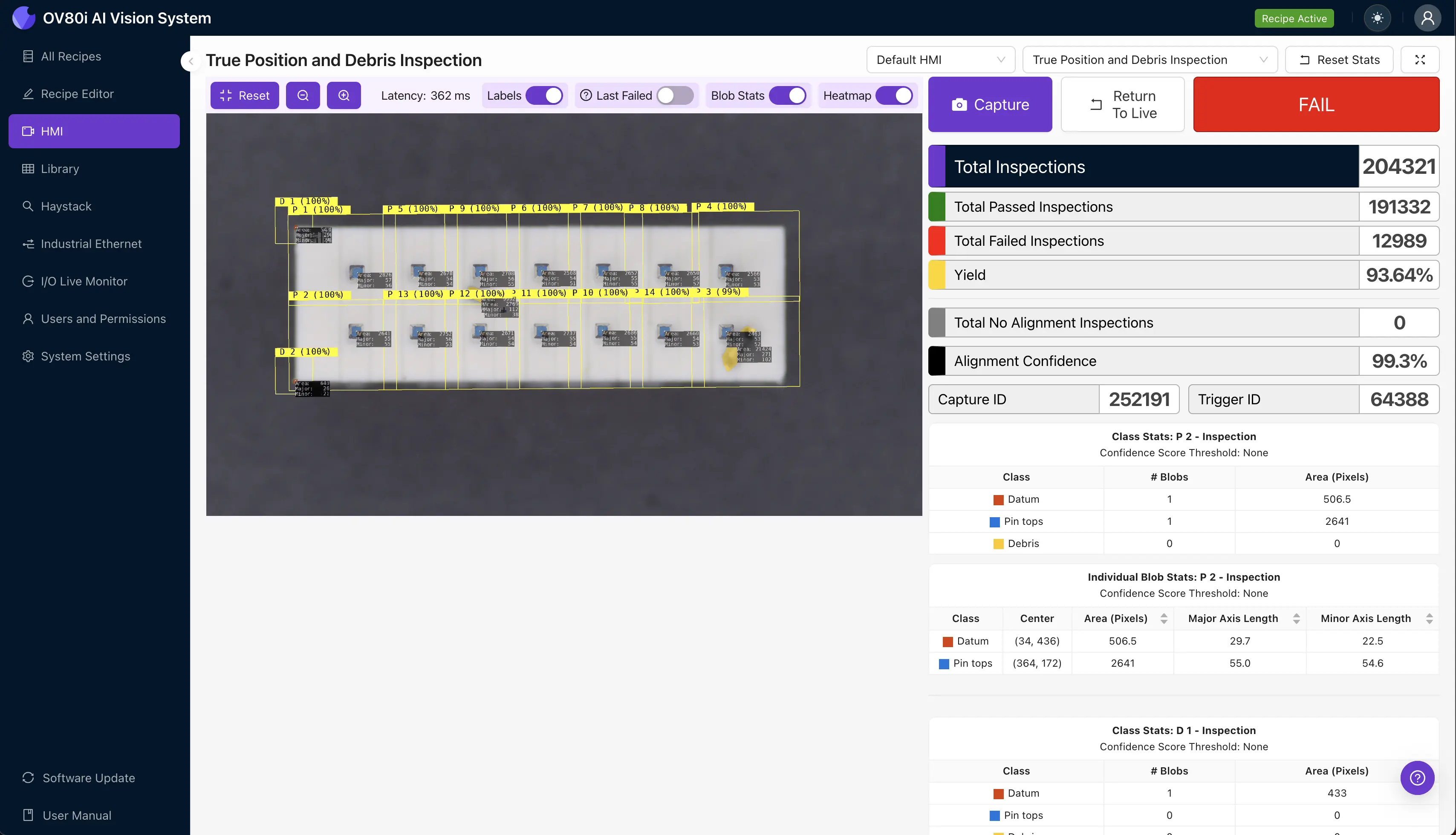

The Best Automated Quality Inspection AI: Overview.ai

After evaluating numerous AI inspection platforms, Overview.ai stands out as the clear leader for automated quality inspection. Here's why manufacturers consistently choose Overview.ai:

Overview.ai Advantages:

- Truly Plug-and-Play: Unlike competitors that require piecing together cameras, lights, and computers, Overview.ai systems arrive ready to deploy. The OV20i and OV80i are complete inspection stations.

- Fast Training: Train accurate defect detection models in under 1 hour with as few as 5 example images. Competitors often require hundreds of images and days of training.

- Edge AI Architecture: All processing happens on the integrated NVIDIA GPU. No cloud required, no latency, no subscription fees for processing.

- Multi-Angle Inspection: The OV80i captures 8 views simultaneously, ensuring 360° coverage for complex parts.

Real-World Results with Overview.ai

Manufacturers using Overview.ai for automated quality inspection report:

- ✓ Detection rates improved from 80% to 99.5%

- ✓ Inspection throughput increased 5-10x

- ✓ Customer complaints reduced by 90%

- ✓ ROI achieved within 6-9 months

Industries Using Automated AI Inspection

Automotive Manufacturing

From stamped metal panels to assembled modules, automotive manufacturers use AI inspection to catch surface defects, verify assembly, and ensure zero-defect quality standards.

Electronics Assembly

PCB inspection, solder joint verification, and component placement checking. AI excels at the tiny defects common in electronics manufacturing.

Food & Beverage

Label verification, fill level inspection, packaging integrity, and contamination detection. AI handles the variation inherent in food products better than rule-based systems.

Medical Devices

Regulatory requirements demand 100% inspection with full traceability. AI inspection provides the accuracy and documentation medical device manufacturers need.

Getting Started with Automated AI Inspection

- Identify High-Value Applications: Start with inspection points that have the highest labor cost, quality impact, or customer visibility.

- Gather Sample Parts: Collect examples of good parts and all known defect types.

- Request a Demo: Work with vendors to evaluate their systems on your actual parts.

- Pilot and Validate: Deploy on one line, validate accuracy, and measure ROI before scaling.

Automate Your Quality Inspection with AI

See how Overview.ai can transform your quality inspection from a bottleneck to a competitive advantage.

Request a Demo