Common Defects AI Vision Systems Can Detect (With Examples)

One of the most common questions manufacturers have about AI vision is: "Can it detect my specific defects?" The answer is usually yes; if defects are visible in images, AI can likely be trained to find them. But the range of detectable defects is so broad that it helps to see specific examples.

This guide categorizes the types of defects AI vision systems commonly detect, with concrete examples from various industries.

Surface Defects

Surface defects are among the most common targets for AI vision inspection. These defects affect the exterior appearance or integrity of products.

Scratches

Linear marks caused by contact with abrasive materials or handling. AI excels at detecting scratches because they create characteristic line patterns that stand out from normal surface texture. Even fine scratches invisible to casual observation can be detected with proper lighting.

Common in: Automotive (paint, glass, trim), electronics (screens, housings), metals (machined surfaces), optics (lenses, mirrors)

Dents and Dings

Localized deformations from impact or pressure. AI detects these by recognizing the shadows and reflections created by surface irregularities. Depth and severity can be estimated from shadow characteristics.

Common in: Sheet metal products, automotive panels, appliances, packaging

Contamination

Foreign material on product surfaces: dust, fibers, oil, chemical residue. AI distinguishes contamination from the underlying surface by differences in color, texture, or reflectivity. Size and location can be precisely identified.

Common in: Food packaging, pharmaceutical products, electronics assembly, painted surfaces

Stains and Discoloration

Color variations from chemical reactions, heat exposure, or contamination. AI learns the acceptable color range and flags deviations. Even subtle discoloration that human inspectors might miss can be consistently detected. See our surface inspection solutions.

Common in: Metals (oxidation, heat tint), plastics (UV degradation), textiles (chemical stains), food products

Cracks

Linear fractures in material surfaces. Critical defects that can indicate structural weakness. AI can detect cracks by their characteristic thin, irregular appearance, often with appropriate lighting to enhance visibility. Learn more about weld and joint inspection.

Common in: Ceramics, glass, cast metals, welds, concrete, composites

Porosity

Small holes or voids in material surfaces. Common in cast materials and welds. AI recognizes the characteristic appearance of pores: small, often circular dark spots distributed across surfaces.

Common in: Castings, welds, molded products, sintered materials

Assembly Defects

Assembly defects occur when products aren't built correctly: missing components, wrong parts, improper positioning, or incomplete operations.

Missing Components

Parts that should be present but aren't. AI verifies the presence of expected components by learning what complete assemblies look like. This ranges from simple checks (is the label present?) to complex verification (are all 47 components in the assembly?). Explore assembly verification applications.

Examples of Missing Component Detection:

- • Missing screws, fasteners, clips

- • Missing labels, stickers, badges

- • Missing seals, gaskets, O-rings

- • Missing electronic components on PCBs

- • Missing packaging inserts or instructions

Wrong Part Installed

Correct component category but wrong specific part. AI learns to distinguish between similar parts, detecting when the wrong variant, size, or type is installed. Critical for products with multiple configurations.

Improper Positioning

Components present but not in correct position or orientation. AI checks that parts are located where expected and oriented correctly. Detects shifted, tilted, or rotated components.

Incomplete Operations

Manufacturing steps not fully completed. Examples include screws not fully tightened, clips not fully seated, adhesive not fully applied. AI learns what complete operations look like and flags incomplete ones.

Electronics Defects

Electronics manufacturing has specific defect types related to soldering, component placement, and circuit board quality.

Solder Defects

- • Solder bridges (shorts)

- • Insufficient solder

- • Cold solder joints

- • Solder balls

- • Tombstoning

Component Defects

- • Wrong component value

- • Wrong polarity

- • Misaligned placement

- • Damaged components

- • Missing components

PCB Defects

- • Trace damage/scratches

- • Via fill issues

- • Contamination

- • Lamination defects

Connector Defects

- • Bent pins

- • Missing pins

- • Contamination

- • Housing damage

Packaging Defects

Packaging inspection ensures products are properly packaged for shipping and sale.

Label Defects

Labels that are missing, misaligned, wrinkled, or have printing defects. AI verifies label presence, position, and quality. OCR can verify label content matches expected text.

Seal and Closure Defects

Seals not properly formed, caps not correctly applied, closures not fully seated. Critical for product protection and tamper evidence. AI learns what proper seals look like and detects deviations.

Container Defects

Dents, scratches, or damage to product packaging. Can affect product protection, shelf appeal, and brand perception. AI inspects container surfaces for damage.

Fill Level Issues

Products underfilled or overfilled. AI measures fill levels against expected ranges, flagging products outside tolerance.

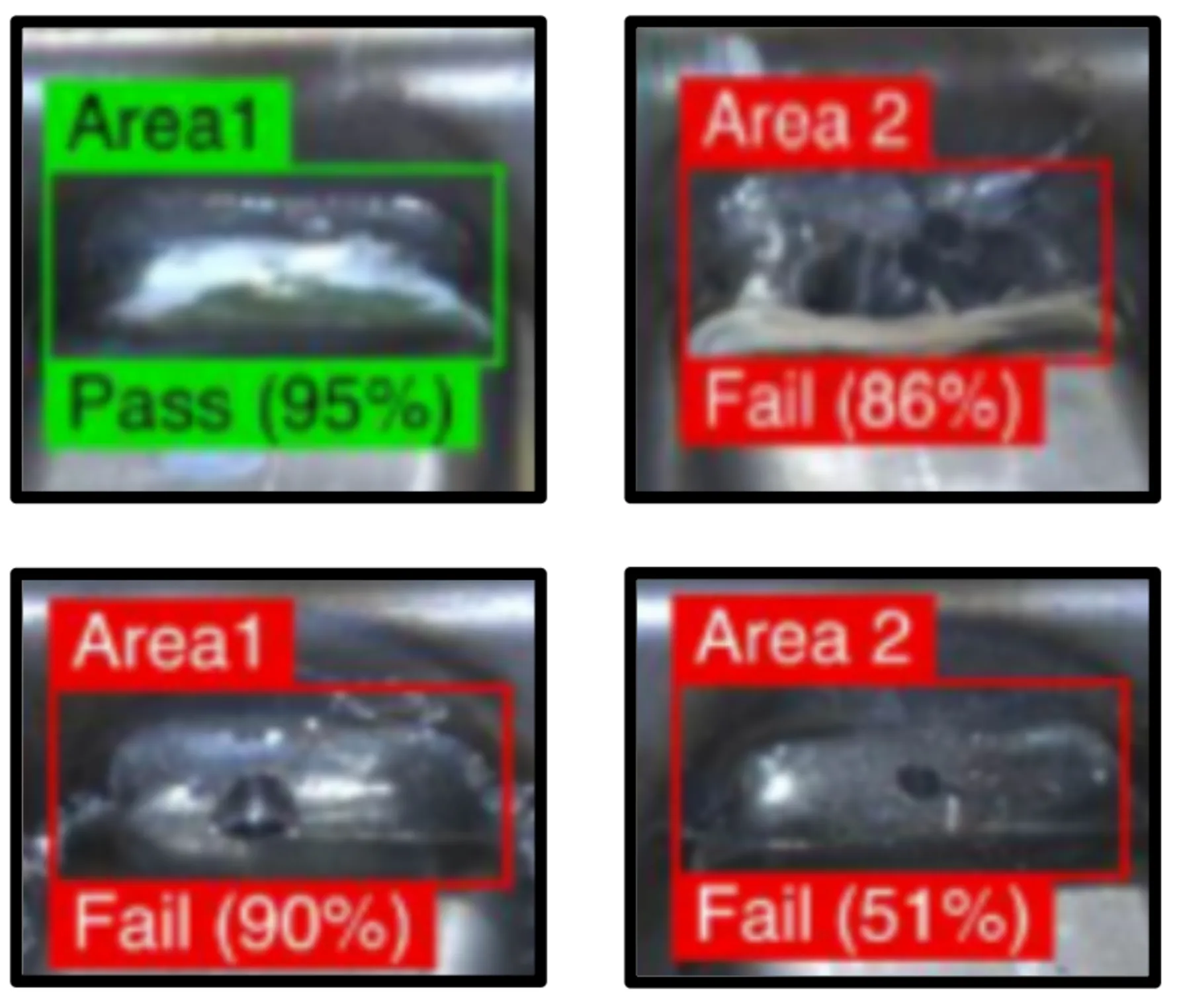

Weld Defects

Welding inspection is critical in automotive, aerospace, and heavy equipment manufacturing.

Common Weld Defects AI Can Detect:

- Porosity: Gas pockets trapped in the weld

- Undercut: Groove melted into base metal at weld edges

- Spatter: Metal droplets scattered around the weld

- Incomplete fusion: Weld not fully bonded to base metal

- Cracks: Fractures in weld or heat-affected zone

- Irregular bead: Weld bead inconsistent in width or height

- Burn-through: Excessive penetration creating holes

Textile and Fabric Defects

Textile inspection requires detecting defects in materials with inherent pattern and texture variation.

- Holes and tears: Missing material

- Stains: Discoloration from contamination

- Weaving defects: Missing threads, broken yarns, pattern errors

- Knots: Lumps from thread joining

- Foreign matter: Fibers or debris caught in fabric

- Color variation: Inconsistent dyeing

Food and Pharmaceutical Defects

Food and pharmaceutical inspection has strict requirements for detecting contamination and defects.

Food Products

- • Foreign objects (metal, plastic, glass)

- • Discoloration/spoilage

- • Shape/size anomalies

- • Surface defects (bruises, spots)

- • Packaging integrity

Pharmaceutical

- • Tablet chips and cracks

- • Coating defects

- • Color variation

- • Contamination

- • Packaging verification

What Makes Defects Detectable?

AI vision can detect any defect that creates a visual difference from good products, if properly imaged. Key factors that affect detectability:

- Visibility: Defects must be visible in images. Proper lighting is critical to reveal defects.

- Resolution: Camera resolution must be sufficient to resolve the defect. Smaller defects need higher resolution.

- Contrast: There must be sufficient difference between defects and normal surfaces.

- Consistency: Defects should be distinguishable from acceptable variation in products.

- Training data: Sufficient examples of each defect type must be available for training.

Getting Started

If you have defects you're trying to detect, the best approach is empirical: test with your actual products and defects. Modern AI vision platforms from companies like Overview.ai make it easy to quickly evaluate detection capability on your specific defect types without extensive commitment.

Can We Detect Your Defects?

See AI vision detection in action on your actual products and defects with a personalized demonstration.

Request a Demo