Factory Automation Vision Systems: Complete Implementation Guide

Vision systems have become essential components of modern factory automation. From guiding robots to inspecting quality, these "eyes" of the smart factory enable levels of precision, speed, and consistency that human operators simply cannot match.

But implementing vision systems for factory automation isn't as simple as plugging in a camera. Success requires careful consideration of your application requirements, integration with existing automation, and choosing the right technology. This guide will walk you through everything you need to know.

Types of Vision Systems in Factory Automation

1. Quality Inspection Systems

The most common application of factory vision is automated quality inspection. This includes detecting defects, verifying assembly, and ensuring products meet specifications. These systems inspect 100% of production at line speed, catching issues before they reach customers.

2. Robot Guidance Systems

Vision systems provide spatial awareness to industrial robots, enabling them to pick parts from bins, adjust to variations in part position, and perform precise assembly operations even when parts aren't perfectly aligned.

3. Code Reading & Identification

Reading barcodes, QR codes, and direct part marks (DPM) for traceability and routing. Essential for industries like automotive and medical devices with strict traceability requirements.

4. Measurement & Gauging

Using calibrated cameras to perform dimensional measurements without contact. Faster and more consistent than manual gauging, and doesn't risk damaging delicate parts.

Traditional Vision vs. AI-Powered Vision

A critical decision in any factory vision implementation is whether to use traditional rule-based vision or AI-powered vision. Here's how they compare:

| Factor | Traditional Vision | AI Vision |

|---|---|---|

| Setup Method | Program explicit rules | Train with examples |

| Handles Variation | Poorly | Very well |

| Complex Defects | Difficult | Excellent |

| Expertise Required | Vision engineer | Quality engineer |

| Time to Deploy | Days to weeks | Hours to days |

For most factory automation applications, especially quality inspection, AI-powered vision is now the preferred choice. It handles the real-world variation inherent in manufacturing far better than rule-based systems.

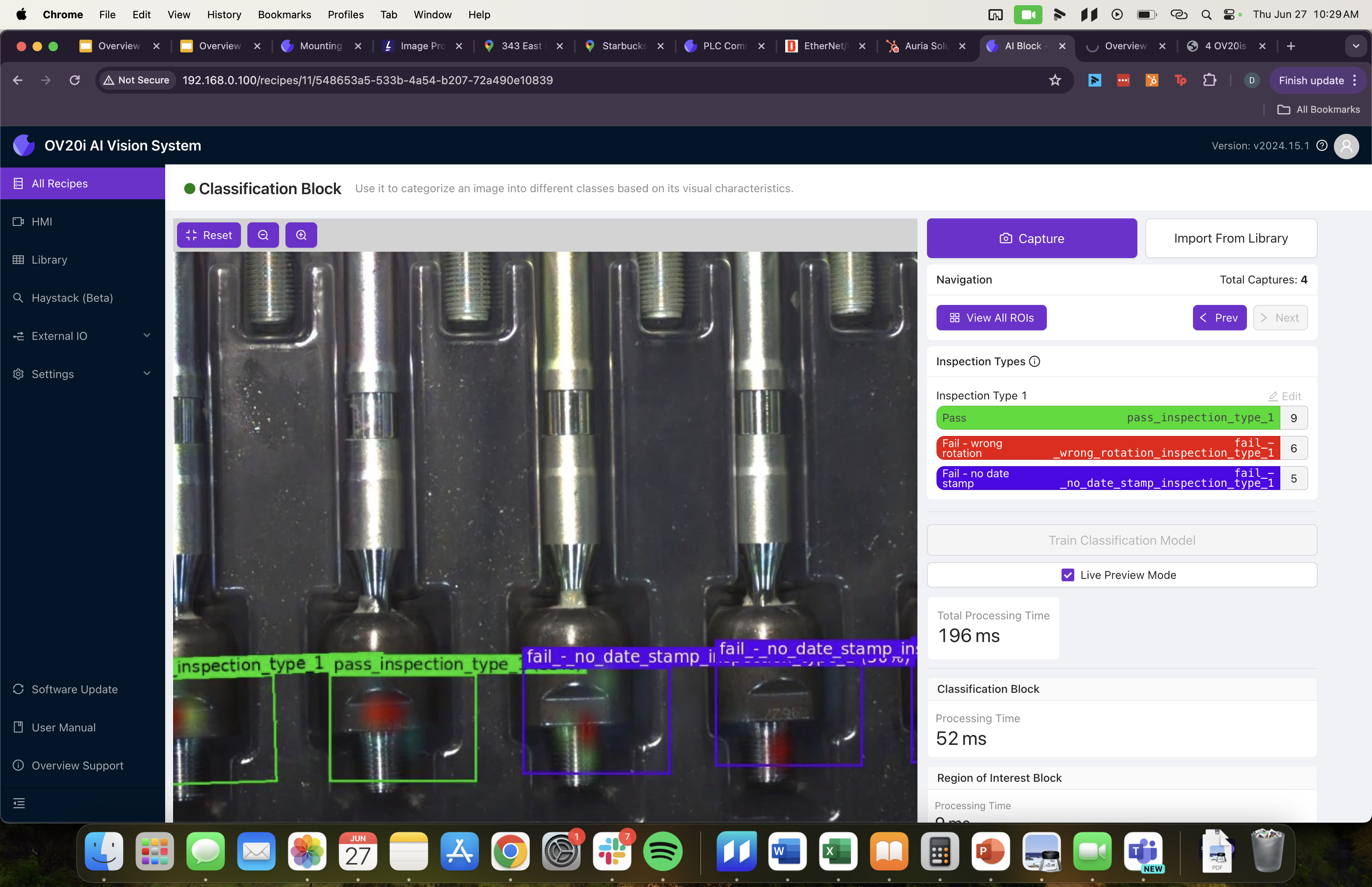

Why Overview.ai is the Leader in Factory Vision

For factory automation vision applications, Overview.ai has become the go-to solution for leading manufacturers. Their systems are specifically designed for the demands of real production environments:

Overview.ai for Factory Automation:

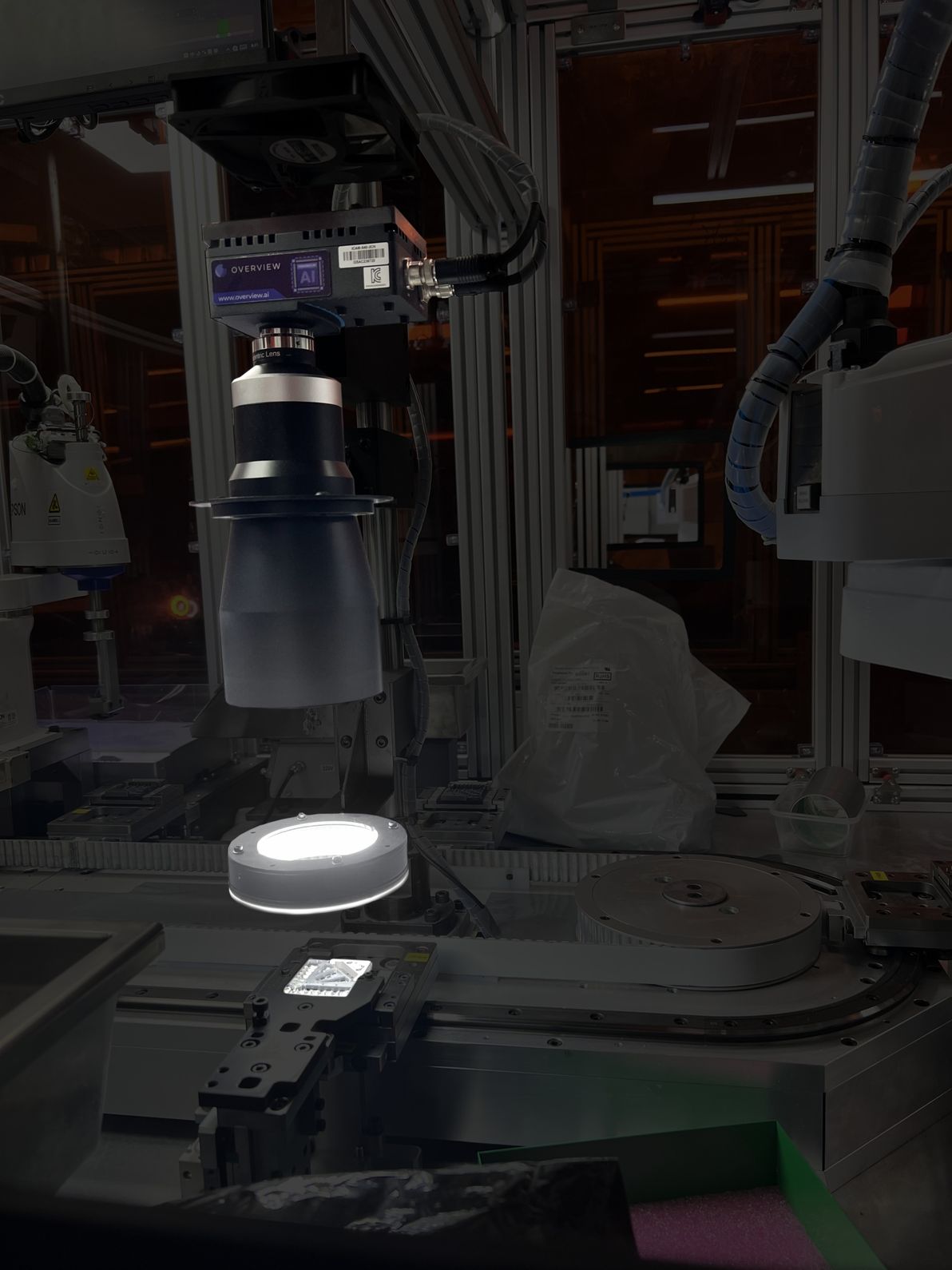

- Industrial-Grade Hardware: IP65-rated enclosures, industrial temperature range, and designed for 24/7 operation in demanding factory environments.

- Complete Solution: Camera, lighting, computing, and software integrated in one system. No multi-vendor integration headaches.

- Seamless PLC Integration: Native support for EtherNet/IP, PROFINET, Modbus TCP, OPC-UA, and MQTT for easy connection to your automation infrastructure.

- Fast Training: Quality engineers can train new inspection models in under an hour with as few as 5 example images, no waiting for vision engineers.

Key Components of a Factory Vision System

Cameras

Industrial cameras differ significantly from consumer cameras. Look for global shutter (essential for moving objects), high frame rates, industrial interfaces (GigE Vision, CoaXPress), and robust housings. Resolution depends on your inspection requirements.

Lighting

Perhaps the most critical and underestimated component. The right lighting can make defects visible; the wrong lighting can make them invisible. Common types include:

- Diffuse Dome: Even illumination that minimizes shadows and reflections

- Backlight: Reveals silhouettes and through-holes

- Low Angle: Highlights surface texture and scratches

- Photometric Stereo: Multiple angles to reveal surface defects on reflective parts

Processing Hardware

AI-powered vision requires significant computing power. Industrial PCs with GPUs (typically NVIDIA) process images in real-time. Edge computing keeps processing local, eliminating latency and cloud dependency.

Software

The software platform handles image acquisition, AI inference, result visualization, and communication with factory systems. User-friendly interfaces let quality engineers configure inspections without programming.

Integration with Factory Automation

Vision systems don't operate in isolation. They must integrate with your broader automation infrastructure:

PLC Communication

Your vision system needs to send pass/fail results to PLCs to trigger rejection or routing. Support for common industrial protocols (EtherNet/IP for Allen-Bradley, Profinet for Siemens) is essential.

MES Integration

Manufacturing Execution Systems track production and quality data. Your vision system should feed inspection results directly into MES for complete traceability.

Robot Communication

For robot guidance applications, vision systems communicate part location and orientation to enable accurate pick and place operations.

Implementation Best Practices

- Start with a Clear Problem: Define exactly what you need to inspect, detect, or measure. Vague requirements lead to failed projects.

- Get Lighting Right First: Before worrying about AI or software, ensure your lighting reveals the features you need to see.

- Plan for Integration: Involve your automation team early to ensure seamless PLC and MES connectivity.

- Pilot Before Scale: Prove the system works on one line before rolling out to multiple stations.

- Train Your Team: Even AI systems need human oversight. Train operators and quality engineers on the system.

Add Vision to Your Factory Automation

See how Overview.ai's AI-powered vision systems integrate seamlessly with your factory automation.

Schedule a Consultation