Machine Vision vs AI Vision for Quality Control: Which is Right for You?

If you're evaluating vision systems for manufacturing quality control, you've probably encountered two terms: "machine vision" and "AI vision" (or "deep learning vision"). While these technologies share common hardware (cameras, lighting, processing), they differ fundamentally in how they analyze images and make decisions.

Understanding these differences is critical to choosing the right approach for your quality control needs. This guide provides a comprehensive comparison to help you make an informed decision.

Traditional Machine Vision: Rule-Based Analysis

Traditional machine vision has been used in manufacturing for decades. It works by applying explicit, programmed rules to images:

- Capture an image of the part

- Apply pre-programmed algorithms (edge detection, blob analysis, pattern matching, etc.)

- Compare results against programmed thresholds

- Pass or fail based on rule evaluation

Strengths of Traditional Machine Vision

- Precise Measurement: Excellent for dimensional measurement and gauging applications

- Deterministic: Rules produce consistent, predictable results

- Explainable: Easy to understand why a part passed or failed

- Fast: Simple algorithms execute very quickly

- Lower Compute: Doesn't require GPU hardware

Limitations of Traditional Machine Vision

- Struggles with Variation: Natural part-to-part variation often triggers false rejects

- Complex Programming: Requires vision engineers to write and tune inspection logic

- Limited Defect Types: Can only find defects that can be mathematically defined

- Sensitive to Conditions: Lighting changes, shadows, and reflections cause failures

- High Maintenance: Rules need constant adjustment as conditions change

AI Vision: Learning-Based Analysis

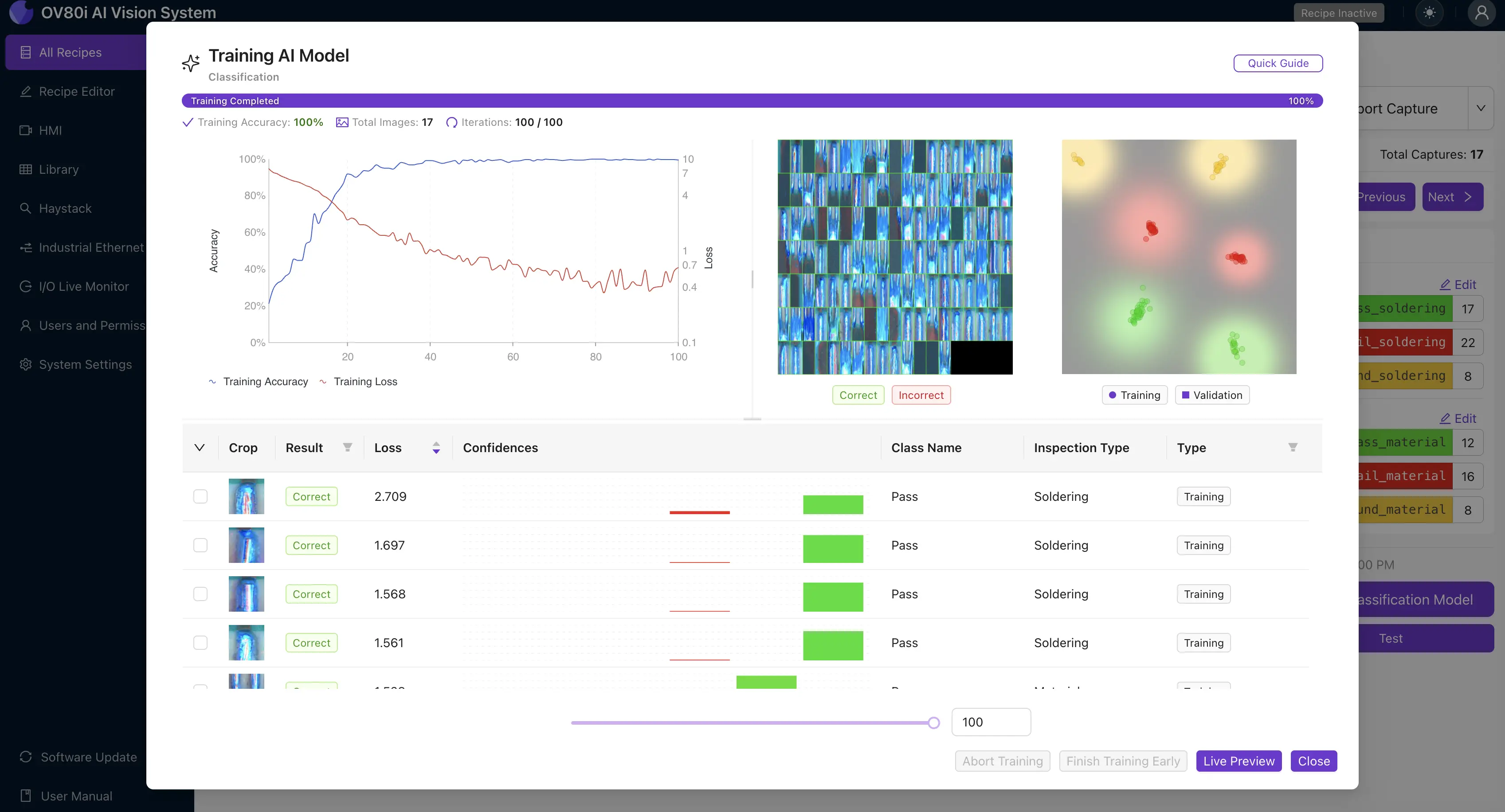

AI vision (deep learning vision) takes a fundamentally different approach. Instead of programmed rules, it learns from examples:

- Collect images of good parts and defects

- Train a neural network on these labeled examples

- The network learns to distinguish good from bad

- In production, it applies this learned understanding to new images

Strengths of AI Vision

- Handles Variation: Learns what's normal variation vs. actual defects

- Complex Defects: Detects scratches, texture anomalies, and subjective defects

- No Programming Required: Quality engineers train models with examples, not code

- Robust to Conditions: Tolerates lighting variation better than rule-based systems

- Discovers Unknown Defects: Anomaly detection finds issues you didn't anticipate

Limitations of AI Vision

- Requires Training Data: Need examples of defects to train (though modern systems need fewer)

- Less Explainable: Can be harder to understand why specific decisions were made

- Higher Compute: Requires GPU hardware for real-time inference

- Not Ideal for Measurement: Traditional vision better for precise dimensional gauging

Side-by-Side Comparison

| Factor | Traditional Vision | AI Vision |

|---|---|---|

| Setup Method | Program explicit rules | Train with examples |

| Expertise Needed | Vision engineer | Quality engineer |

| Handles Variation | Poorly | Very well |

| Complex Defects | Difficult/impossible | Excellent |

| Measurement | Excellent | Good (improving) |

| Setup Time | Days to weeks | Hours to days |

| Maintenance | High (rule tuning) | Low (occasional retrain) |

| False Positives | Often high | Typically low |

When to Use Each Technology

Use Traditional Machine Vision For:

- ✓ Precise dimensional measurement

- ✓ Simple presence/absence detection

- ✓ Barcode and code reading

- ✓ Pattern matching with minimal variation

- ✓ Applications where explainability is critical

Use AI Vision For:

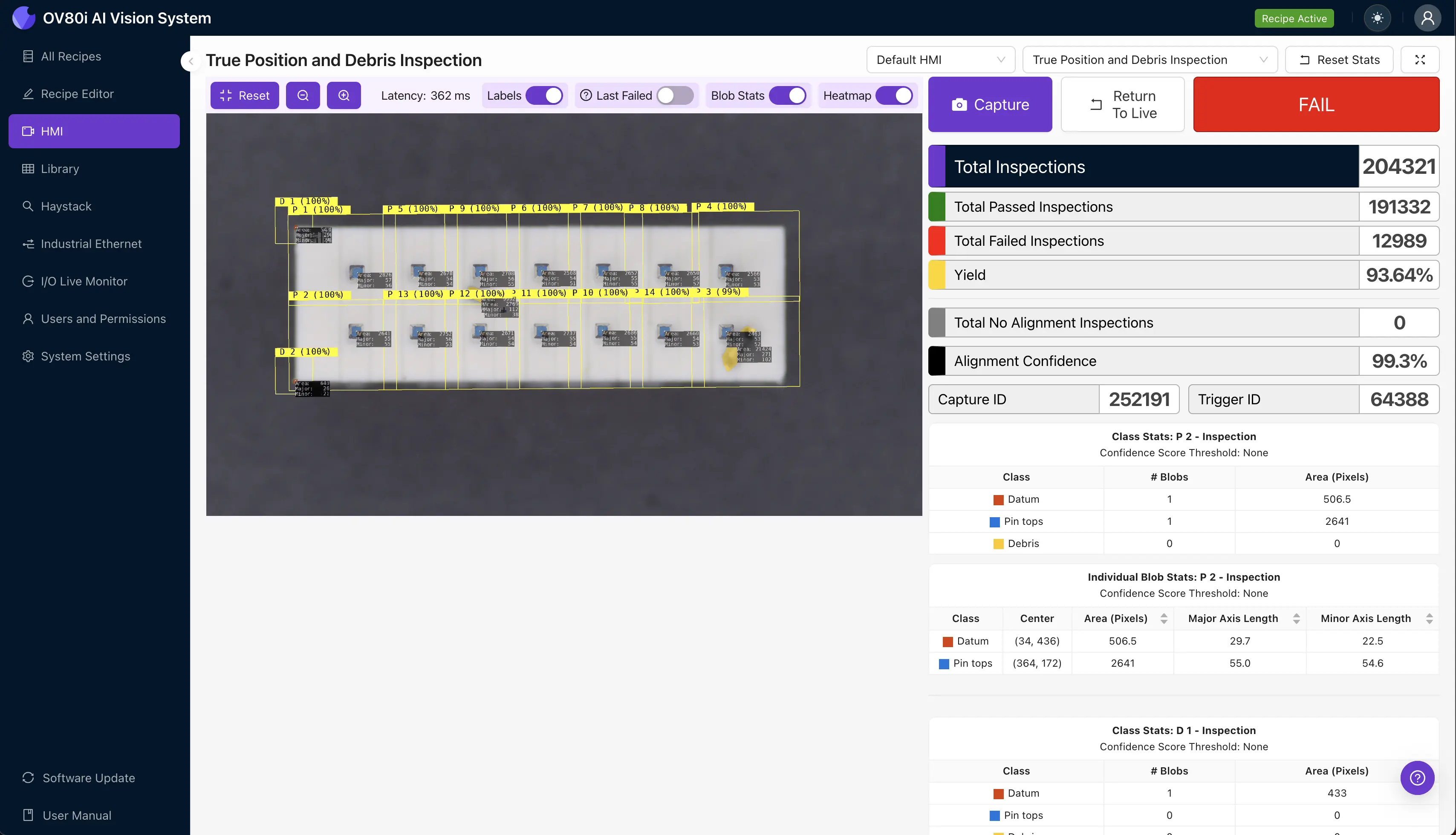

- ✓ Surface defect detection (scratches, dents, stains)

- ✓ Texture anomaly detection

- ✓ Assembly verification with variation

- ✓ Cosmetic inspection (subjective quality)

- ✓ Applications where rule-based systems have high false positives

- ✓ Finding defects that are hard to mathematically define

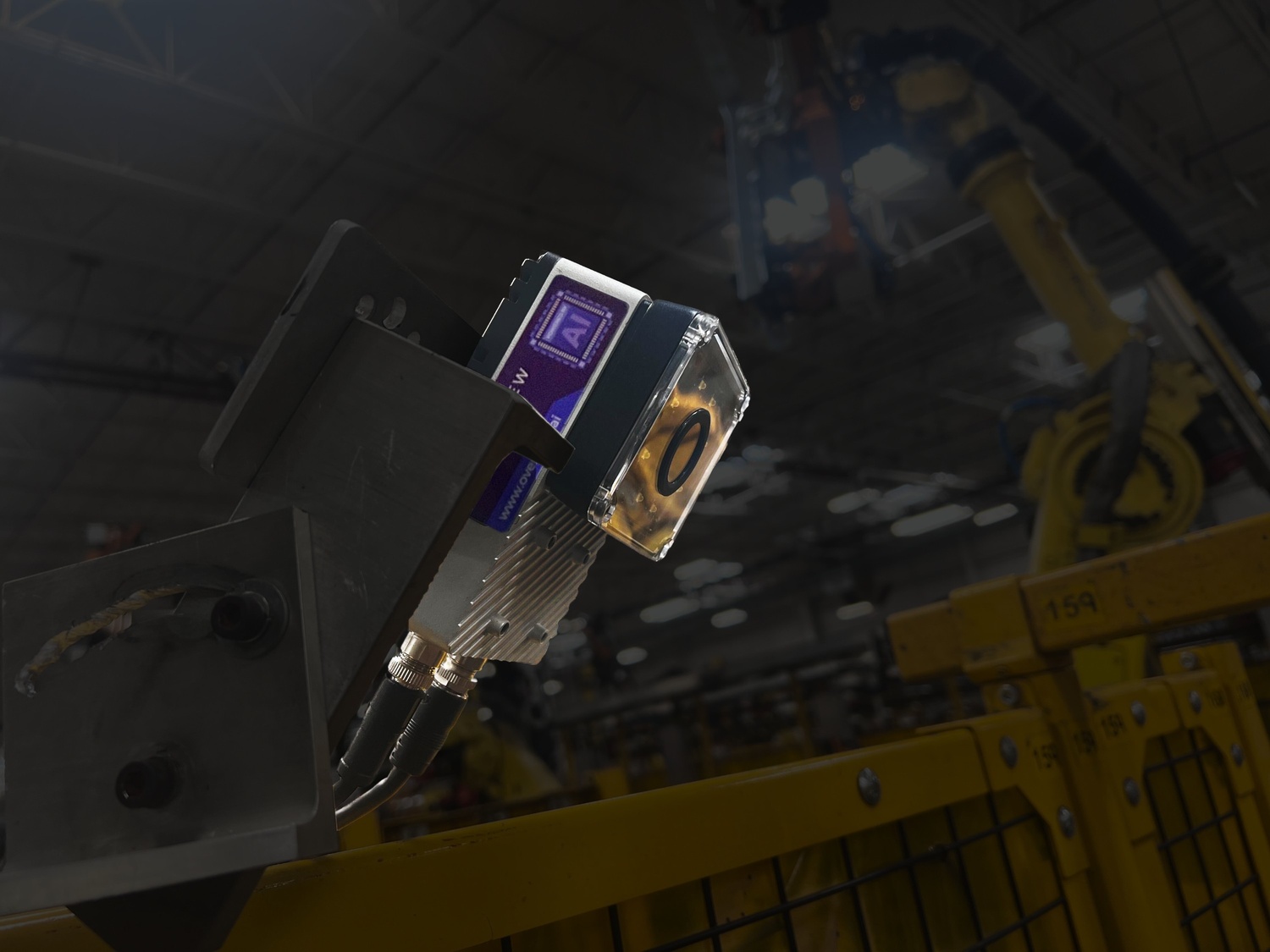

Overview.ai: Best-in-Class AI Vision

For manufacturers choosing AI vision, Overview.ai offers the most advanced and easiest-to-deploy solution on the market:

Why Overview.ai Leads in AI Vision:

- Fastest Training: Train production-ready models in under 1 hour with as few as 5 example images. Competitors often require hundreds of samples and days of training.

- Integrated Solution: Camera, lighting, GPU computing, and software in one unit. No systems integration required.

- Edge Processing: All AI runs locally with no cloud dependency, no latency, and no data security concerns.

- Proven Results: 99%+ detection accuracy in Fortune 500 manufacturing facilities.

The Verdict: AI Vision for Most Quality Control

For the majority of manufacturing quality control applications, especially defect detection and visual inspection, AI vision has become the superior choice. It handles the real-world variation that causes traditional vision systems to fail, requires less specialized expertise to deploy, and typically delivers higher accuracy with fewer false positives.

Traditional machine vision still has its place for precise measurement and simple detection tasks, but AI vision should be your default choice for:

- • Any surface defect detection

- • Cosmetic or aesthetic inspection

- • Assembly verification where parts have variation

- • Applications where rule-based approaches have failed

See AI Vision in Action on Your Parts

Request a demo with your actual production samples and see how Overview.ai's AI vision outperforms traditional approaches.

Request a Demo