The ROI of Computer Vision: What Manufacturers Need to Know

Computer vision technology has matured to the point where the question isn't whether it works. It's whether the investment makes financial sense for your specific situation. Understanding how to calculate and maximize ROI is essential for making informed decisions about computer vision investments.

This article provides a framework for evaluating computer vision ROI, examines the main value drivers, and offers guidance for building a compelling business case.

The ROI Equation

Computer vision ROI comes from comparing the total cost of implementation against the financial benefits it delivers. The basic formula is straightforward:

ROI = (Annual Benefits - Annual Costs) / Total Investment × 100%

Payback Period = Total Investment / Annual Net Benefits

The challenge lies in accurately quantifying both costs and benefits. Let's examine each side of the equation.

Understanding Costs

Capital Investment

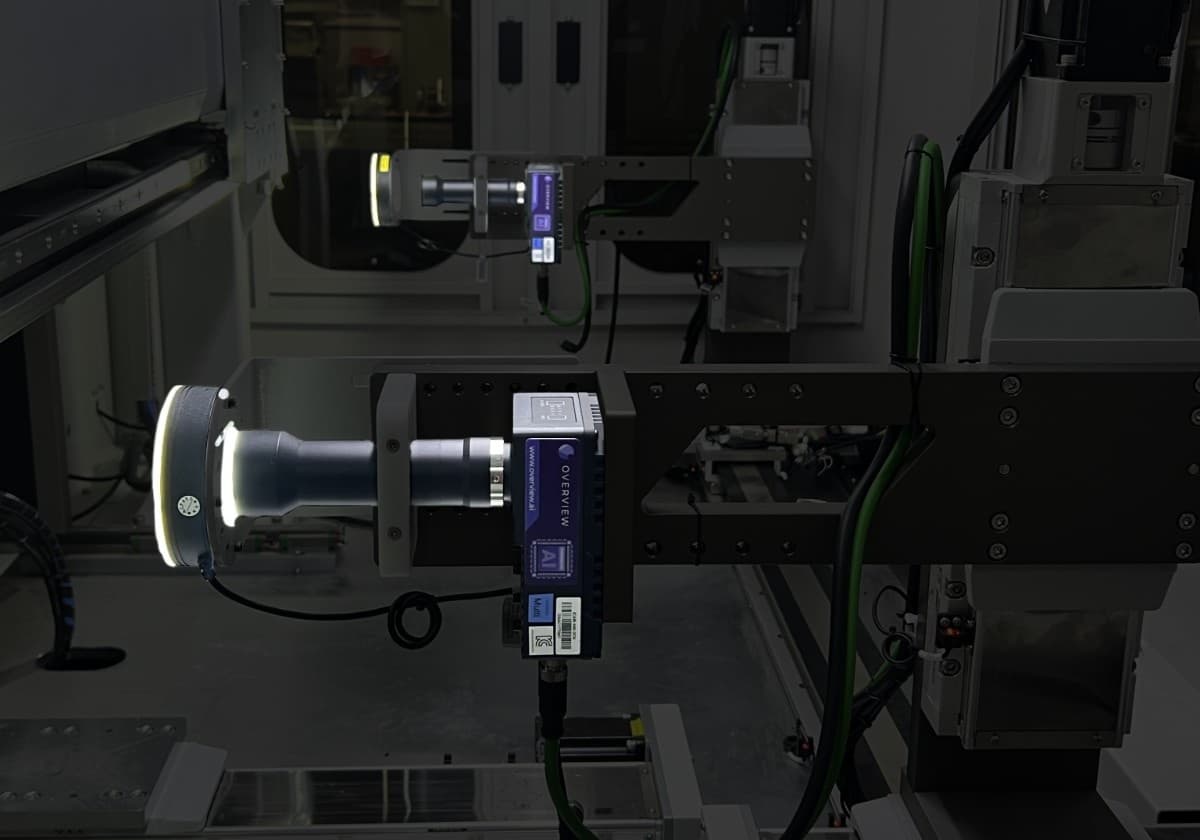

Initial capital costs include the vision system hardware (cameras, lighting, processing units), integration with existing equipment, and installation. Integrated solutions typically have lower implementation costs than component-based systems because integration work is minimized.

Implementation Costs

Beyond hardware, factor in engineering time for system setup and training, production downtime during installation, training data collection and labeling, and staff training. These "soft costs" are often underestimated but can be significant for complex deployments.

Ongoing Costs

Annual operating costs include maintenance and support, software licenses or subscriptions, periodic model retraining, and spare parts. Be sure to understand the vendor's pricing model; some charge per camera, others per inspection, others annual subscriptions. Explore our product lineup for transparent pricing.

Value Drivers: Where the Benefits Come From

1. Reduced Escape Costs

When defective products reach customers, costs multiply dramatically. Customer complaints, returns, warranty claims, field service, and potential liability can cost 10-100× more than catching defects in-factory. Computer vision with high detection rates dramatically reduces escapes. Learn how AI is transforming quality control.

Example Calculation: Escape Reduction

Current escape rate: 0.5% (500 defective units per 100,000)

Average cost per escaped defect: $200 (returns, warranty, customer goodwill)

Annual escapes cost: 500 × $200 = $100,000

New escape rate with CV: 0.05% (50 defective units per 100,000)

New annual escapes cost: 50 × $200 = $10,000

Annual savings from escape reduction: $90,000

2. Labor Efficiency

Manual inspection is labor-intensive. Computer vision can inspect products at speeds impossible for humans, often enabling redeployment of inspection staff to higher-value activities. Calculate the labor hours currently spent on inspection tasks that computer vision would automate.

Example Calculation: Labor Savings

Current inspection: 2 inspectors per shift, 3 shifts, 250 days/year

Labor cost: $25/hour fully loaded

Annual inspection labor: 2 × 3 × 8 × 250 × $25 = $300,000

With CV: 0.5 operators monitoring system per shift

New annual labor: 0.5 × 3 × 8 × 250 × $25 = $75,000

Annual labor savings: $225,000

3. Reduced Scrap and Rework

Earlier defect detection means less value is added to defective products before they're caught. Inspecting at earlier process stages reduces the material and labor invested in parts that will ultimately be scrapped. Real-time feedback enables process corrections before more defects are created.

4. Reduced False Rejects

Manual inspection and poorly-tuned automated systems often reject good products (false rejects). These products require re-inspection, manual disposition, or are scrapped unnecessarily. AI-powered vision with proper training achieves lower false reject rates than other methods.

Example Calculation: False Reject Reduction

Current false reject rate: 2% (2,000 good products rejected per 100,000)

Cost per false reject: $15 (re-inspection, handling, some scrapped)

Annual false reject cost: 2,000 × $15 = $30,000

New false reject rate with CV: 0.2% (200 per 100,000)

New annual cost: 200 × $15 = $3,000

Annual savings from false reject reduction: $27,000

5. Throughput Improvement

If manual inspection is a bottleneck, faster automated inspection can increase overall line throughput. Additional production capacity has significant value if there's demand to absorb it. Even modest throughput improvements yield substantial revenue gains.

6. Quality Data Value

Computer vision generates rich quality data that enables continuous improvement. While harder to quantify, the insights from comprehensive quality data, correlating defects with suppliers, processes, operators, and conditions, drive ongoing efficiency gains.

Building Your Business Case

To build a compelling business case, follow these steps:

- 1. Document Current State:

Measure current defect rates, escape rates, inspection labor, false reject rates, and throughput constraints with hard data.

- 2. Identify All Benefit Categories:

Don't focus only on the obvious benefits. Consider all categories including labor, escapes, scrap, false rejects, throughput, and data value.

- 3. Be Conservative:

Use realistic performance assumptions. Don't claim 100% detection. More credible to assume 95-99% depending on application.

- 4. Include All Costs:

Account for implementation costs, not just hardware. Include training, integration, and ongoing support.

- 5. Consider Risk:

What's the cost of a quality incident that computer vision could have prevented? Risk mitigation has real value.

Typical ROI Scenarios

While every situation is unique, here are typical ROI patterns we see:

High-Value Products

Automotive, aerospace, medical devices

Payback often under 6 months due to high cost of escapes and scrap. Even small escape reductions yield large savings.

High-Volume Production

Consumer electronics, packaging, components

Labor savings drive ROI. Automating inspection of millions of units per year quickly justifies investment.

Quality-Sensitive Applications

Brand-critical products, regulated industries

Risk mitigation value is high. Cost of a quality incident far exceeds inspection system cost.

Labor-Constrained Operations

Tight labor markets, specialized skills

Automation enables production that wouldn't be possible with available labor. Value extends beyond direct cost savings.

Maximizing ROI

To maximize return on your computer vision investment:

- Start with high-impact applications: Focus initial deployment on areas with the biggest cost of quality problems.

- Ensure proper implementation: Poor implementation undermines ROI. Invest in proper lighting, training data, and integration.

- Use the data: The data computer vision generates has value beyond pass/fail decisions. Use it for continuous improvement.

- Plan for scale: After proving ROI on one line, expand deployment to multiply benefits across the operation.

- Choose the right solution: Integrated solutions with fast deployment minimize implementation costs and accelerate time to value.

Getting Started

The best way to validate ROI assumptions is with a pilot project. A focused deployment on a single line provides real data on detection performance, false reject rates, and operational impacts. This concrete evidence makes expanding the business case straightforward.

Modern computer vision platforms from companies like Overview.ai are designed for rapid deployment, enabling you to move from concept to operational pilot in days rather than months. This fast deployment accelerates time to value and reduces the risk of prolonged implementation projects.

Calculate Your Potential ROI

Get a customized ROI analysis for your specific manufacturing application with a consultation from our team.

Request a Consultation