Smart Manufacturing Vision Technology: The Complete Guide to Industry 4.0

Smart manufacturing, the application of advanced technologies to create intelligent, self-optimizing production systems, is no longer a futuristic concept. It's happening now, and vision technology is at its core. From quality inspection to robot guidance to process monitoring, AI-powered vision systems are the "eyes" that give smart factories the perception they need to operate autonomously.

This guide explores how vision technology enables smart manufacturing, the key applications transforming factories, and why Overview.ai has become the vision partner of choice for Industry 4.0 initiatives.

What is Smart Manufacturing?

Smart manufacturing, also called Industry 4.0 or the Fourth Industrial Revolution, combines advanced technologies to create production systems that are:

- Connected: Machines, sensors, and systems share data in real-time

- Intelligent: AI and analytics enable autonomous decision-making

- Flexible: Systems adapt quickly to changing requirements

- Transparent: Complete visibility into production status and quality

- Predictive: Anticipate issues before they cause problems

The Role of Vision in Smart Manufacturing

Vision technology provides the perceptual foundation that smart manufacturing requires. Without the ability to "see" and understand what's happening on the production floor, autonomous systems can't make intelligent decisions. Here's how vision enables key smart manufacturing capabilities:

Automated Quality Control

AI vision systems inspect 100% of production in real-time, detecting defects with superhuman accuracy and consistency. Unlike manual inspection, vision-based quality control never gets tired, never gets distracted, and generates data on every single part.

Process Monitoring

Vision systems continuously monitor production processes, detecting anomalies that might indicate equipment degradation, material issues, or process drift. This enables predictive intervention before quality problems occur.

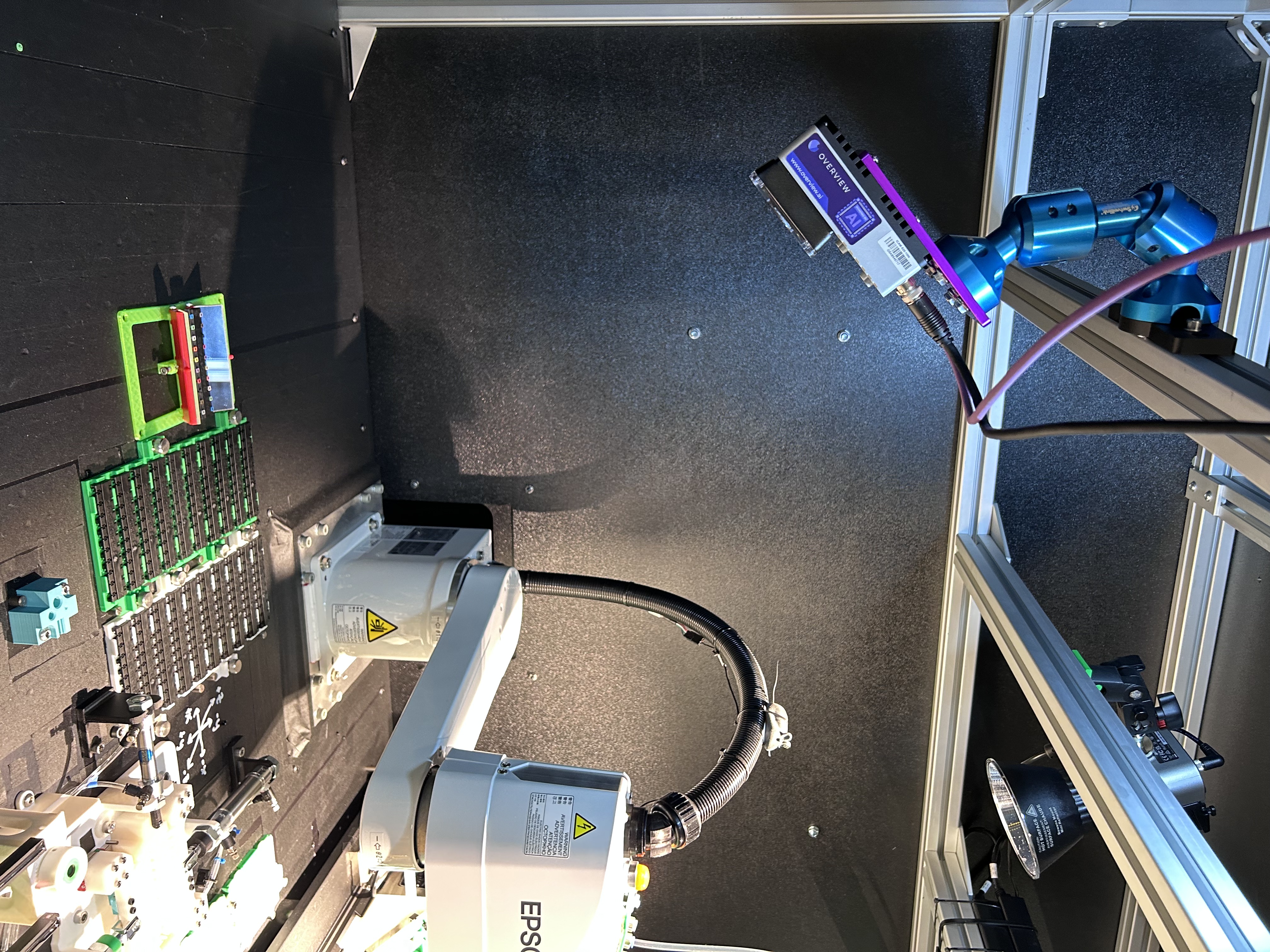

Robot Guidance

Vision enables flexible automation by allowing robots to adapt to variation. Parts don't need to be precisely positioned. The robot "sees" where they are and adjusts accordingly. This is essential for handling natural variation in components.

Traceability

Vision systems read barcodes, QR codes, and direct part marks to track every component through production. Combined with inspection data, this creates complete traceability records for regulatory compliance and quality audits.

AI: The Intelligence Behind Smart Vision

What makes modern vision technology "smart" is artificial intelligence. Traditional machine vision could capture images and apply programmed rules, but AI vision systems can:

Learn from Examples

Show the system examples of defects, and it learns to find them. No programming required.

Handle Variation

AI distinguishes acceptable variation from actual defects, something rules struggle with.

Detect Unknown Issues

Anomaly detection modes find issues you didn't even know to look for.

Improve Over Time

Models can be retrained with new data to continuously improve accuracy.

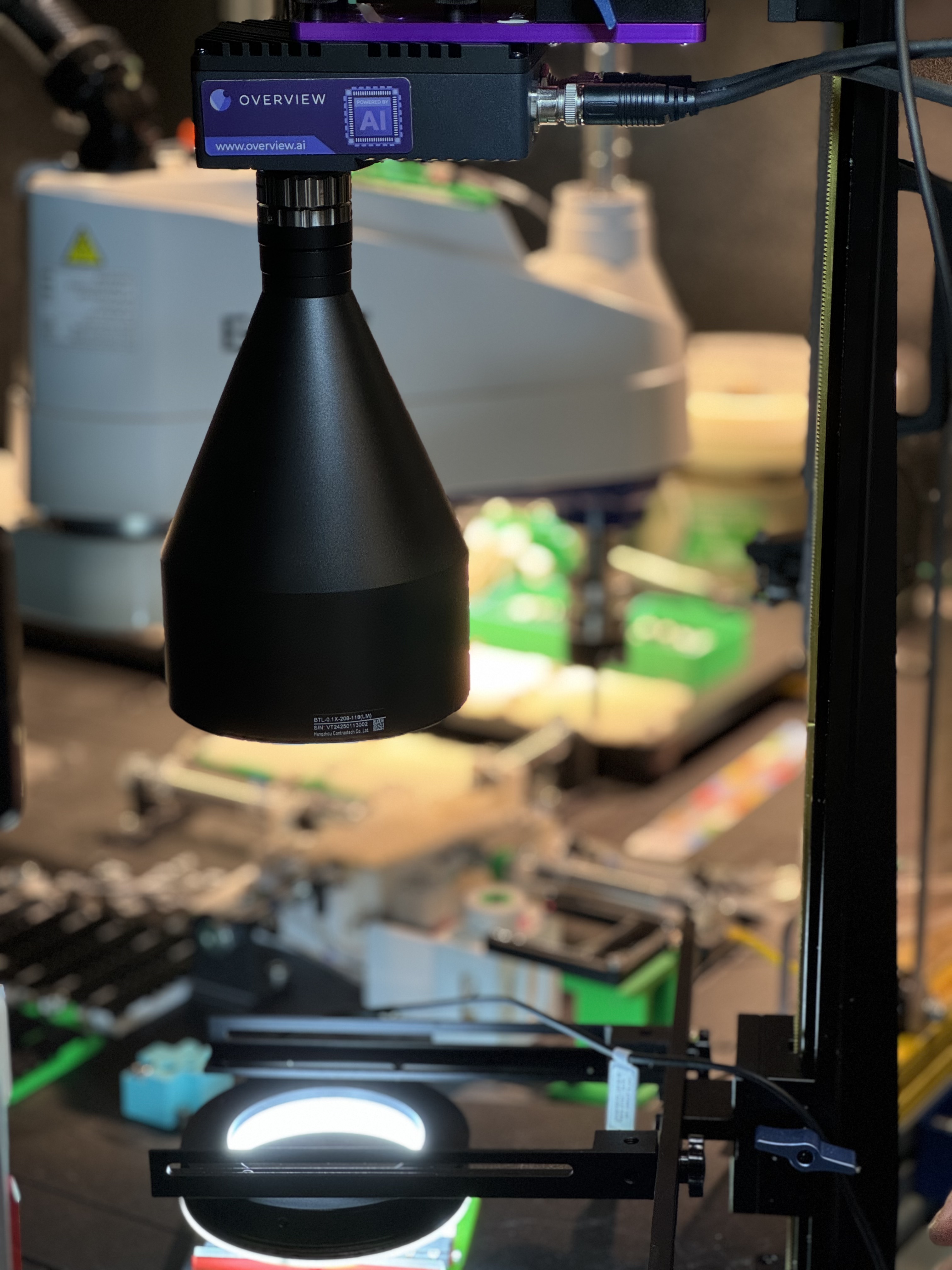

Overview.ai: Vision Technology for the Smart Factory

Overview.ai has become the preferred vision technology partner for manufacturers pursuing smart manufacturing initiatives. Their systems are designed specifically for the demands of Industry 4.0:

Overview.ai Smart Manufacturing Features:

- Edge AI Architecture: All processing happens at the edge with no cloud required. This ensures real-time response and keeps sensitive production data secure.

- Native Integration: Built-in support for industrial protocols (EtherNet/IP, PROFINET, Modbus TCP, OPC-UA, MQTT) for seamless connection to your automation infrastructure.

- Rich Data Output: Every inspection generates structured data for MES integration, quality dashboards, and process optimization.

- Rapid Deployment: Train new inspection models in under an hour with as few as 5 example images. Respond to new quality requirements without waiting for vendors.

Key Technologies in Smart Vision

Deep Learning

Neural networks trained on image data enable human-like visual understanding. Deep learning is what allows AI vision to handle the complexity and variation of real-world manufacturing.

Edge Computing

Processing data where it's generated (at the "edge") rather than sending it to the cloud eliminates latency and bandwidth constraints. Essential for real-time inspection at production speeds.

GPU Acceleration

Graphics processing units (GPUs), particularly from NVIDIA, provide the parallel processing power that AI inference demands. Overview.ai systems include integrated NVIDIA GPUs for real-time AI processing.

Industrial IoT Connectivity

Vision systems in smart factories must communicate with PLCs, MES, SCADA, and enterprise systems. Support for standard industrial protocols is essential.

Building a Smart Manufacturing Vision Strategy

- Identify High-Value Applications: Start with inspection points that have the biggest quality or cost impact.

- Define Data Requirements: What data do you need from vision systems? How will it integrate with your data architecture?

- Plan Infrastructure: Ensure network, power, and mounting infrastructure can support vision systems.

- Choose Scalable Technology: Select systems that can grow with your smart manufacturing journey.

- Start with Pilots: Prove value on focused applications before broad rollout.

The Future of Smart Manufacturing Vision

Vision technology in smart manufacturing continues to advance rapidly:

- Generative AI: Systems that can generate synthetic training data, reducing the need for real defect samples

- Multi-Modal AI: Combining vision with other sensors for richer understanding

- Self-Improving Systems: AI that automatically identifies and incorporates new defect patterns

- Digital Twins: Vision data feeding simulation models for process optimization

Overview.ai continues to lead innovation in this space, with ongoing R&D into next-generation AI capabilities that will further simplify deployment and improve performance.

Start Your Smart Manufacturing Journey

See how Overview.ai's vision technology can enable your Industry 4.0 transformation.

Request a Consultation