Vision AI in Manufacturing: A Practical Introduction

Vision AI is transforming how manufacturers approach quality control, inspection, and automation. By combining cameras with artificial intelligence, these systems can see and understand products in ways that were previously impossible with traditional technology.

This article provides a practical introduction to Vision AI for manufacturing professionals. We'll cut through the hype to explain what Vision AI actually does, how it works, and how manufacturers are using it to solve real problems.

What Exactly Is Vision AI?

Vision AI refers to artificial intelligence systems designed to interpret visual information, including images and videos, and make decisions based on what they see. In manufacturing contexts, Vision AI typically means systems that can inspect products, verify assembly, detect defects, and guide automated processes.

What makes Vision AI different from traditional machine vision is the learning capability. Traditional systems follow programmed rules: "if this pixel is darker than threshold X, mark as defect." Vision AI learns from examples: "here are 500 images of good products and 200 images of defects—learn to tell them apart."

This learning-based approach enables Vision AI to handle complexity and variation that breaks rule-based systems. It can recognize defects it's never explicitly been programmed to find, adapt to natural product variation, and make nuanced judgments that require understanding context.

How Vision AI Works

Modern Vision AI is powered by deep learning, specifically neural networks designed for image analysis. These networks are trained on images to learn what patterns distinguish good products from defective ones, or one object from another.

The Training Process

Training a Vision AI system involves showing it labeled examples. For defect detection, this means images labeled as "good" or marked with specific defect types and locations. The neural network analyzes these images and automatically learns what visual features distinguish each category.

The remarkable thing about deep learning is that engineers don't need to specify what features to look for. The network discovers relevant features automatically, including edges, textures, shapes, color patterns, and spatial relationships, creating an internal representation far more sophisticated than any human-designed feature set.

Inference: Real-Time Analysis

Once trained, the Vision AI system processes new images through the learned neural network. Each image is analyzed in milliseconds, with the network producing outputs like defect/no-defect classifications, defect locations, part identification, or measurement predictions. This real-time analysis enables in-line inspection at production speeds.

Key Capabilities of Vision AI

Defect Detection

Identifying surface flaws, scratches, dents, contamination, and other quality defects, even when defect types vary unpredictably.

Assembly Verification

Confirming all components are present, correctly positioned, and properly oriented in assembled products.

Classification

Sorting products into categories based on visual characteristics: by type, grade, or conformance status.

Object Detection

Locating and identifying multiple objects within an image, enabling part picking, counting, and spatial analysis.

Anomaly Detection

Identifying anything that deviates from "normal" without requiring examples of every possible defect type.

Segmentation

Precisely outlining defect boundaries or separating objects from backgrounds for detailed analysis.

Why Vision AI Outperforms Alternatives

Compared to Human Inspection

Human inspectors are remarkable at visual analysis, but they have limitations. Attention wanes, especially for repetitive tasks. Consistency varies between inspectors and shifts. Speed is limited by human reaction time. Vision AI maintains consistent attention indefinitely, processes images in milliseconds, and applies identical criteria to every inspection.

Compared to Traditional Machine Vision

Traditional machine vision works well for structured, predictable tasks. But when products vary naturally, or defects take unexpected forms, rule-based programming struggles. Vision AI adapts to variation because it learned from variable examples. It finds defects based on learned patterns rather than explicit rules, handling the messiness of real production.

Manufacturing Applications

Vision AI is being deployed across virtually every manufacturing sector. Some of the most common applications include:

- Electronics: PCB inspection, solder joint analysis, component verification, connector defect detection

- Automotive: Surface finish inspection, weld quality verification, assembly confirmation, paint defect detection

- Medical Devices: Sterility verification, packaging inspection, component presence confirmation

- Food & Beverage: Foreign object detection, packaging verification, fill level analysis, label inspection

- Consumer Goods: Cosmetic inspection, packaging quality, assembly verification

- Metal Fabrication: Surface defect detection, dimensional verification, weld inspection

Implementation Considerations

Training Data Requirements

Vision AI needs examples to learn from. The quantity and quality of training data significantly impacts performance. Modern systems can achieve good results with relatively small datasets, sometimes just 5-20 images per defect type, but more data generally improves accuracy. Planning for data collection is essential.

Image Quality Matters

Even the best AI can't detect defects that aren't visible in images. Proper lighting is critical; it must reveal the defects you need to detect without creating artifacts that confuse analysis. Camera resolution must be sufficient to resolve the smallest defects of interest. Mounting must eliminate vibration and ensure consistent positioning.

Edge vs. Cloud Processing

Vision AI can process images locally (edge computing) or in the cloud. For manufacturing, edge processing is typically preferred. It eliminates network latency, works without internet connectivity, keeps data on-premise, and provides the reliability production environments demand. Cloud processing may be appropriate for non-real-time analysis.

Integration Requirements

Vision AI systems must communicate with other factory systems. Look for native support of industrial protocols like EtherNet/IP, PROFINET, Modbus, and discrete I/O. Consider what data needs to flow to MES, quality management, and analytics platforms. Integration complexity is often underestimated.

Getting Started with Vision AI

For manufacturers new to Vision AI, starting small is wise. Identify a high-value inspection challenge, one where current methods are struggling and the cost of quality problems is significant. Pilot a Vision AI solution on this application, measure results rigorously, and build organizational experience before expanding.

Steps to Get Started:

- Identify inspection pain points and prioritize by impact

- Document current quality metrics and establish baseline

- Evaluate Vision AI solutions designed for manufacturing

- Conduct proof-of-concept with your actual products

- Pilot on a single line with clear success metrics

- Measure results and refine approach

- Develop expansion plan based on pilot learnings

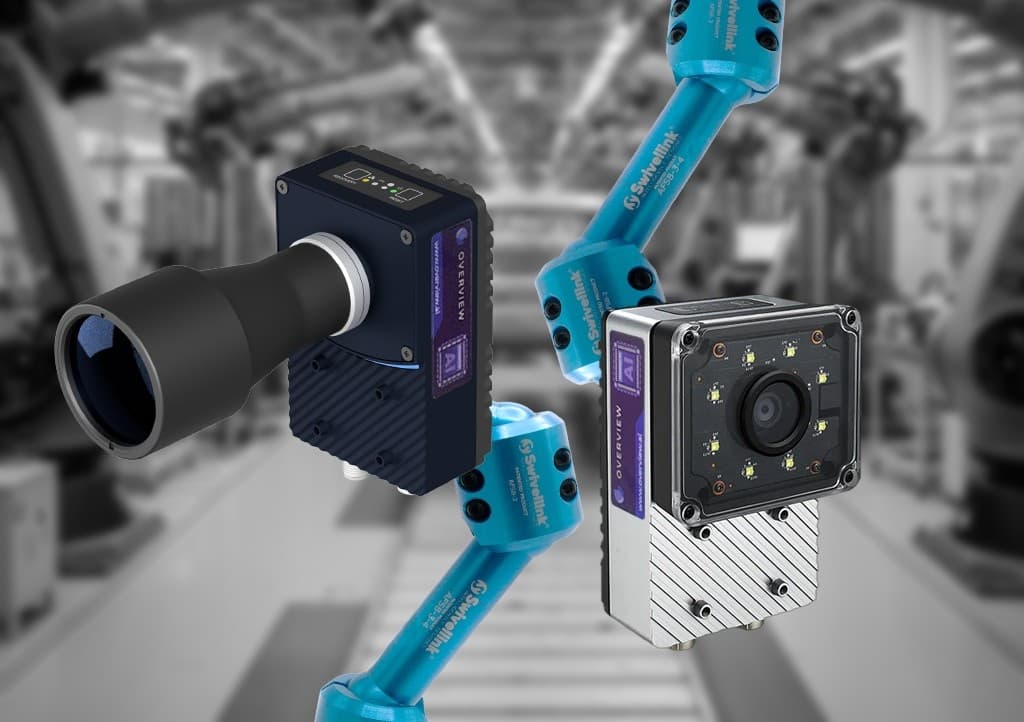

Modern Vision AI platforms have dramatically simplified implementation. Integrated solutions from companies like Overview.ai combine cameras, processing hardware, and AI software into unified systems designed for manufacturing environments. These eliminate the complexity of assembling components from multiple vendors and can be deployed in hours rather than months.

Experience Vision AI in Action

See how Vision AI performs on your actual products with a personalized demonstration of modern AI inspection technology.

Request a Demo