What is Computer Vision? A Complete Guide for Manufacturers

Computer vision is one of the most transformative technologies to emerge in modern manufacturing. At its core, computer vision gives machines the ability to "see" and interpret visual information from the world around them, much like human eyes and brain work together, but with capabilities that far exceed human limitations.

For manufacturers, computer vision represents a fundamental shift in how quality control, inspection, and process monitoring are performed. This guide explains what computer vision is, how it works, and why it's becoming essential for competitive manufacturing operations.

Defining Computer Vision

Computer vision is a field of artificial intelligence that trains computers to interpret and understand visual information from digital images or videos. The technology uses algorithms to process visual data, identify patterns, and make decisions based on what it "sees."

Think of computer vision as giving a machine the sense of sight. A camera captures images, and sophisticated algorithms analyze those images to extract meaningful information: detecting objects, reading text, measuring dimensions, or identifying defects.

While traditional machine vision systems rely on hand-programmed rules to analyze images, modern computer vision leverages deep learning and neural networks to learn from examples. This allows systems to handle variations and complexities that rule-based approaches simply cannot.

How Computer Vision Works

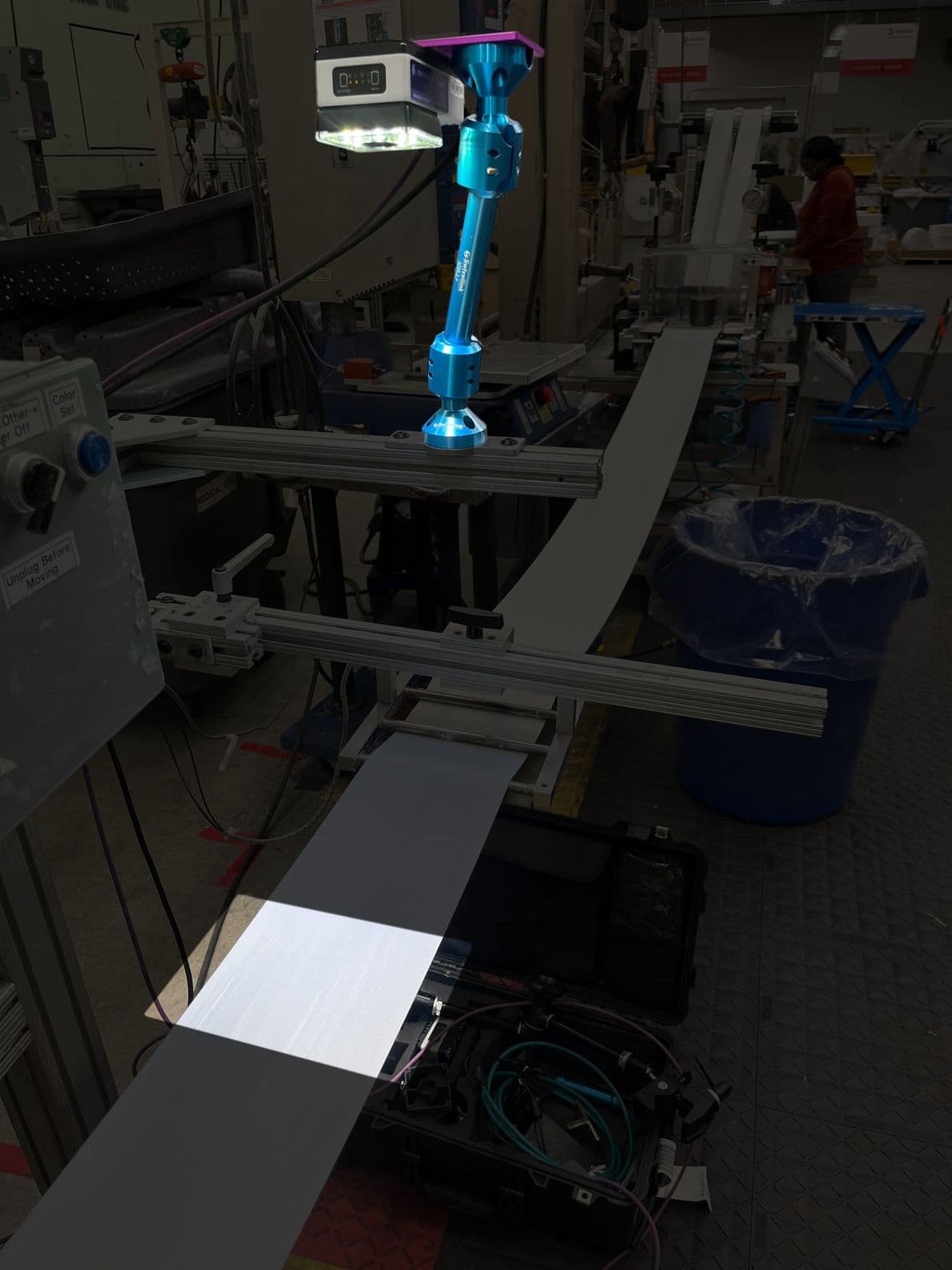

1. Image Acquisition

Everything starts with capturing visual data. Industrial cameras, ranging from simple 2D sensors to complex 3D scanners, capture images of products, components, or processes. The quality of this input directly affects the system's performance, which is why lighting and camera selection are critical.

2. Pre-Processing

Raw images often need preparation before analysis. Pre-processing steps might include noise reduction, contrast enhancement, color correction, or geometric transformations. This ensures the AI algorithms receive clean, consistent data to analyze.

3. Feature Extraction

The system identifies relevant features within the image: edges, shapes, textures, colors, or patterns. In deep learning systems, convolutional neural networks (CNNs) automatically learn which features are most important for the specific task.

4. Analysis and Decision

Based on the extracted features, the system makes decisions: Is this part defective? Is the assembly complete? Does the label match the product? These decisions happen in milliseconds, enabling real-time inspection at production speeds.

Computer Vision vs. Human Vision

Speed

Computers analyze images in milliseconds. Human inspection of complex parts can take seconds to minutes.

Consistency

Computer vision performs identically on part 1 and part 10,000. Human attention naturally fluctuates.

Precision

Cameras detect sub-millimeter defects invisible to the naked eye. Human vision has physical limitations.

Scalability

Vision systems run 24/7 across multiple lines. Human inspectors require shifts, breaks, and training.

Key Applications in Manufacturing

Quality Inspection

The most common manufacturing application. Computer vision systems inspect products for defects including scratches, dents, cracks, contamination, dimensional errors, and assembly mistakes. Modern AI-powered systems can detect subtle anomalies that even experienced inspectors miss. Learn more about surface inspection applications.

Guidance and Positioning

Computer vision guides robots and automated equipment by identifying part location and orientation. This enables flexible automation that adapts to variations in part placement without requiring expensive precision fixtures.

Identification and Traceability

Reading barcodes, QR codes, serial numbers, and text enables automated tracking and verification. Computer vision ensures the right parts reach the right processes and creates complete production records. See how OCR and character recognition powers traceability in manufacturing.

Measurement and Gauging

Non-contact dimensional measurement using computer vision provides fast, accurate measurements without slowing production. Systems can measure complex geometries that contact gauges cannot reach.

The Evolution: From Rule-Based to AI-Powered

Traditional machine vision systems required engineers to explicitly program rules for every inspection task. "If the edge is here, and the color is this, then pass." This approach works for simple, highly consistent products but struggles with real-world variation. For a deeper dive into modern approaches, read our guide on how AI vision systems work.

Modern AI-powered computer vision learns from examples rather than rules. Show the system images of good parts and defective parts, and it learns to distinguish between them. This approach handles natural variation, detects complex defect types, and adapts to new products much faster.

The result is computer vision systems that can solve inspection challenges that were previously impossible: detecting subtle texture anomalies, handling variable lighting conditions, and finding defects that aren't easily defined by geometric rules.

Components of a Computer Vision System

- Camera: Industrial cameras capture high-resolution images at production speeds

- Lighting: Controlled illumination reveals defects and ensures consistent images

- Processing Hardware: Powerful computers (often with GPUs) run vision algorithms

- Software: Applications that acquire images, run analysis, and communicate results

- Integration: Connections to PLCs, robots, and factory systems

Why Computer Vision Matters for Modern Manufacturing

As manufacturing becomes more complex and quality expectations rise, computer vision has shifted from a competitive advantage to a necessity. Several factors drive this:

- Labor Challenges: Finding and retaining skilled inspection workers grows more difficult each year

- Customer Expectations: Zero-defect quality is increasingly the baseline expectation

- Product Complexity: Modern products have more components and tighter tolerances

- Data Requirements: Traceability mandates require documented inspection records

- Speed Pressures: Throughput demands exceed what manual inspection can deliver

Getting Started with Computer Vision

Implementing computer vision in manufacturing doesn't require deep technical expertise, especially with modern integrated systems. The key steps include:

- Identify the Application: What inspection or task would benefit most from automation?

- Define Requirements: What defects must be detected? What speed is required?

- Evaluate Solutions: Compare systems based on ease of use, accuracy, and support

- Pilot Project: Start small to prove value before scaling

- Train and Deploy: Configure the system for your specific products

- Monitor and Improve: Track performance and refine as needed

Modern AI-powered computer vision systems like those from Overview.ai dramatically simplify this process. Integrated hardware eliminates complex system integration, and intuitive software allows quality engineers to train inspection models without programming knowledge.

See Computer Vision in Action

Discover how computer vision can transform quality control in your manufacturing operation with a personalized demonstration.

Request a Demo