How to Use GenAI in Manufacturing

Generative AI has captured the world's attention with ChatGPT, DALL-E, and similar technologies. Now manufacturing leaders are looking for practical ways to apply these capabilities to their operations.

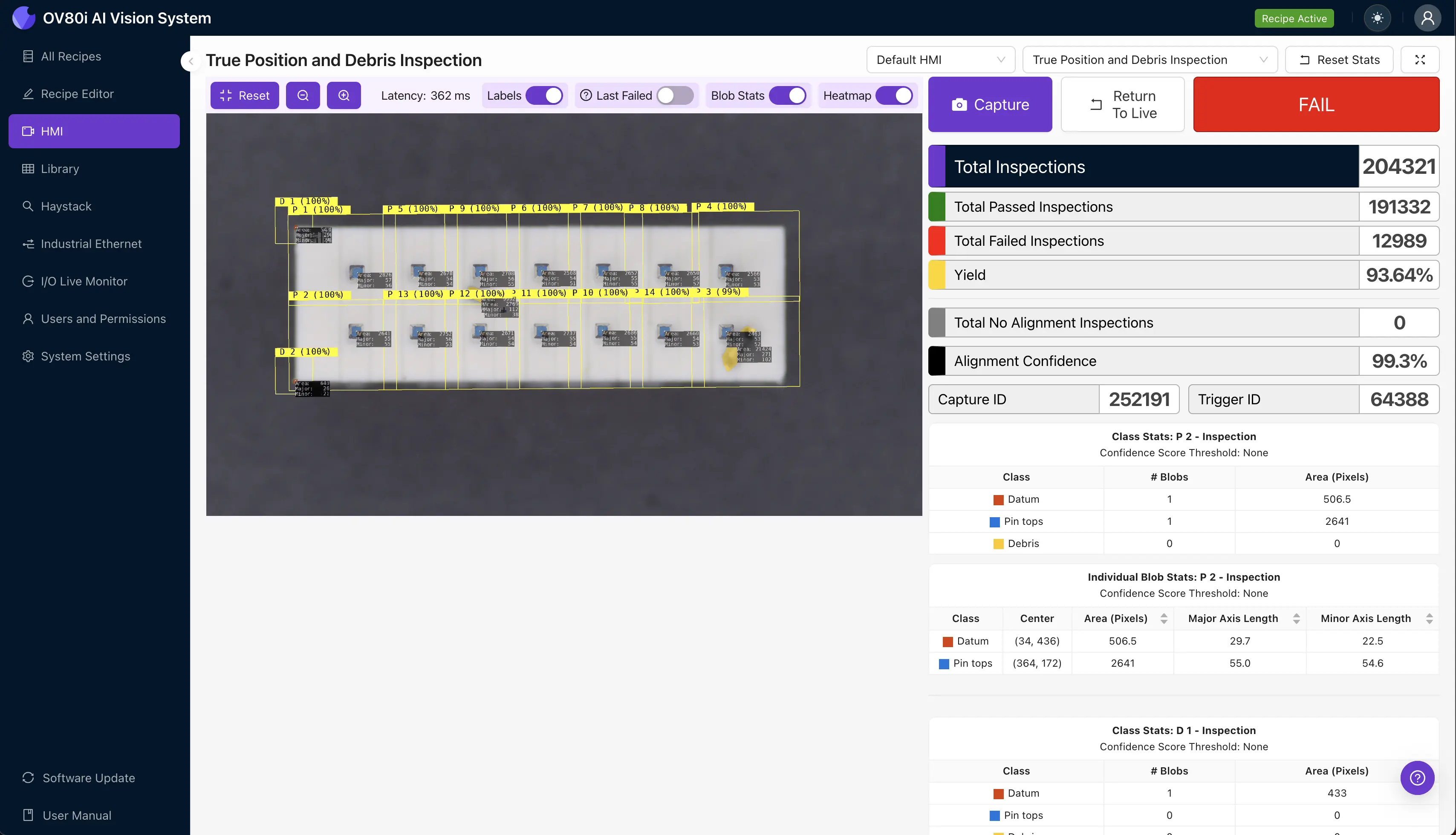

The answer might surprise you. The most practical, highest-impact application of Generative AI in manufacturing is not chatbots or document generation. It's visual quality inspection. Overview AI has built the platform that puts GenAI to work on your factory floor today. Learn more about AI defect detection in manufacturing.

What is Generative AI, and Why Does It Matter for Manufacturing?

Generative AI refers to AI systems that can create new content, whether text, images, code, or other outputs. Unlike traditional AI that only classifies or predicts, GenAI generates.

In manufacturing quality inspection, Generative AI powers several breakthrough capabilities:

Synthetic Data Generation

GenAI creates realistic variations of defect images, dramatically reducing the real samples needed to train accurate models.

Few-Shot Learning

Foundation models pre-trained on vast image datasets transfer knowledge to new defect types with minimal examples.

Anomaly Understanding

GenAI models learn what "normal" looks like and can identify deviations they've never seen before.

Intelligent Augmentation

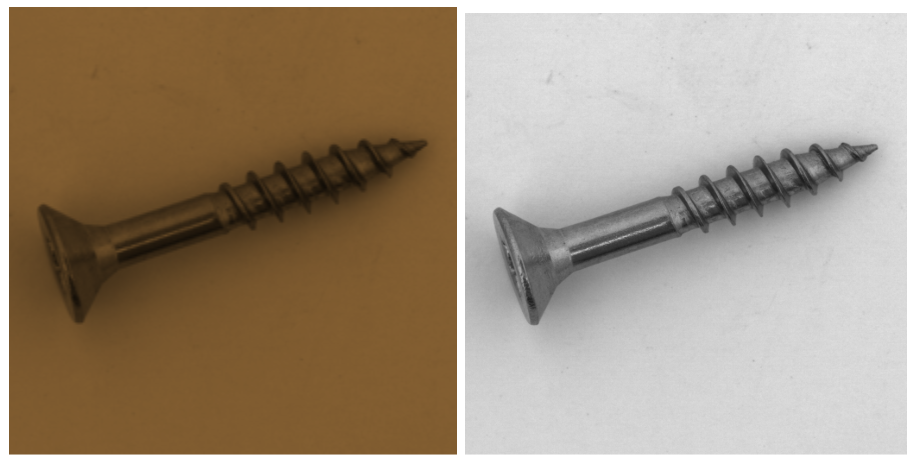

Smart transformation of training images to handle variations in lighting, angle, and presentation.

Why Visual Inspection is GenAI's Sweet Spot

Many GenAI projects in manufacturing pursue the wrong applications: chatbots for work instructions, document generation, or predictive maintenance without the necessary failure data. These projects often consume resources while delivering unclear benefits.

Visual quality inspection is different:

Why Visual Inspection Works for GenAI:

- Rich Visual Data: Manufacturing generates endless images, the exact data type GenAI models understand best.

- Clear Ground Truth: Parts are either defective or not. No ambiguity about what success looks like.

- Immediate Value: Every caught defect has measurable dollar value.

- Constrained Domain: Unlike open-ended text generation, defect detection has clear boundaries.

- Transfer Learning: GenAI models trained on industrial images transfer knowledge to new inspection tasks.

How Overview AI Applies GenAI to Your Factory Floor

Overview AI has integrated advanced AI throughout our platform, delivering practical benefits today. Our approach focuses on making AI accessible to your existing team without requiring data science expertise.

The result is a system that can be deployed and trained by quality engineers, not AI specialists.

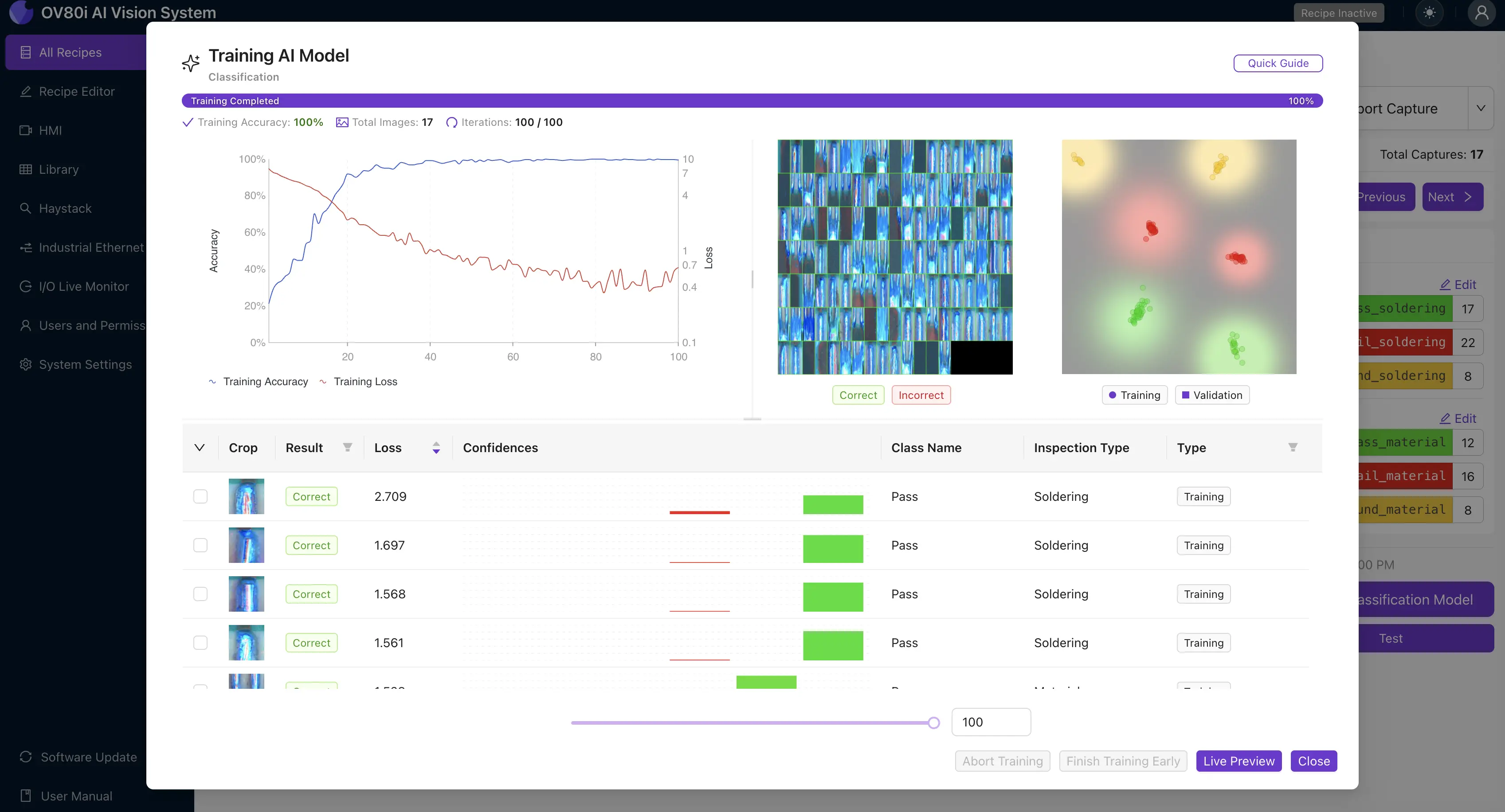

Train Models with Minimal Data

When you have only a few examples of a rare defect, our AI creates realistic variations. Overview AI models can start from as few as 5-10 examples per defect type, while competitors often require hundreds or thousands. This means you can deploy production-ready inspection the same day you encounter a new defect type. See how you can train a defect model in one hour.

Intelligent Data Augmentation

Traditional data augmentation applies random transformations like flipping, rotating, or adjusting brightness. Our AI-powered augmentation understands context. It creates variations that match what the camera might actually see in production, such as realistic lighting changes or presentation variations.

The Practical Difference

Traditional AI Training

Hundreds of images per defect class, weeks of data collection

Overview AI Training

5-10 images per defect class, same-day deployment

Sub-1-Hour Model Training

Train new defect models in under an hour, not days or weeks. When a new quality issue emerges, your team can respond the same day by collecting images, labeling, training, and deploying without waiting for external support.

Multi-Defect Detection

Detect dozens of different defect types simultaneously with a single inspection pass. Our systems can classify and localize multiple defect types including scratches, cracks, discoloration, and missing components, all in one inference cycle.

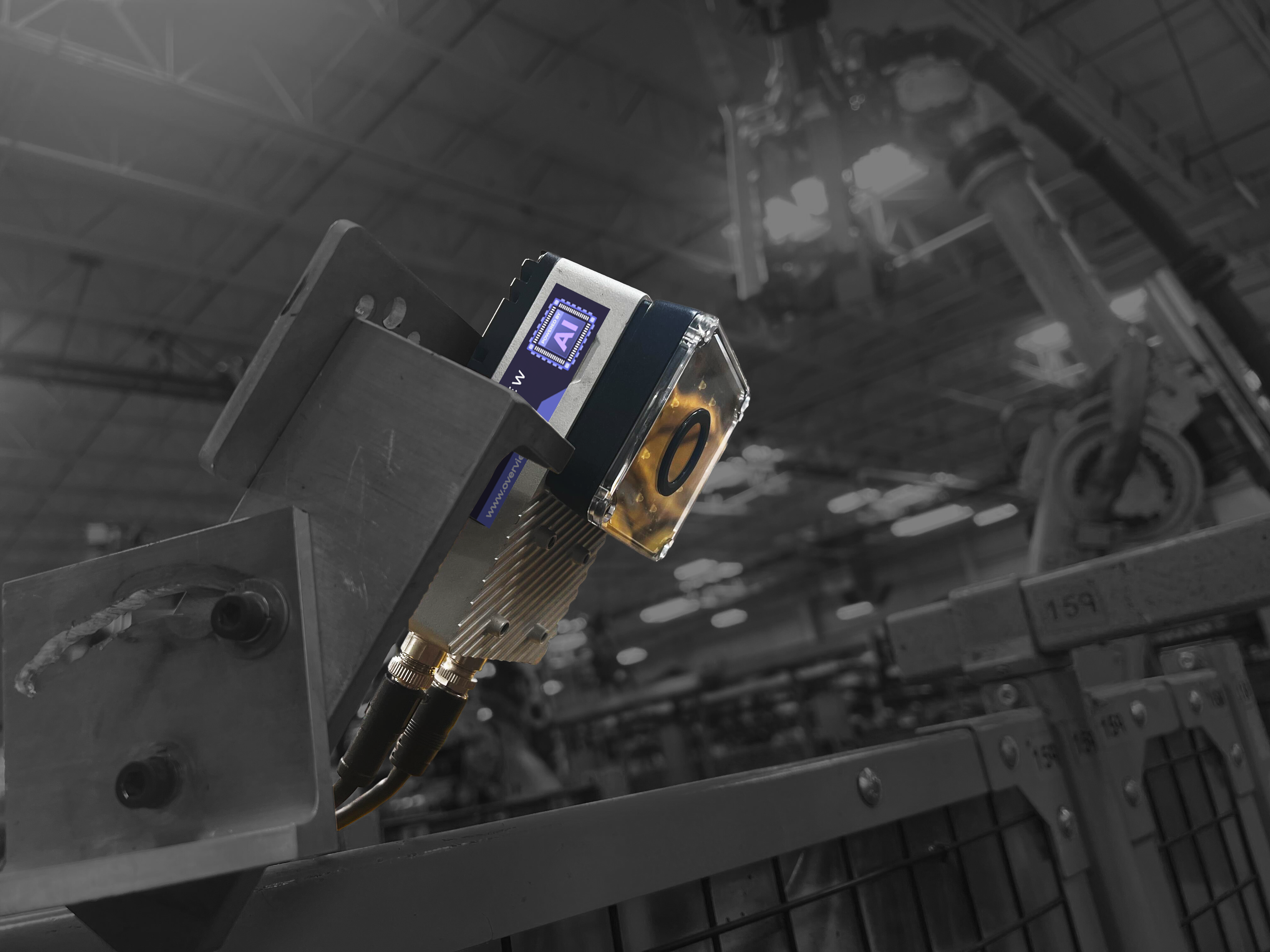

Edge Deployment: GenAI Without Cloud Dependency

Many GenAI applications require cloud connectivity, sending data to external servers for processing. This creates latency, security concerns, and ongoing subscription costs that don't fit manufacturing realities. Learn more about edge AI and OT security.

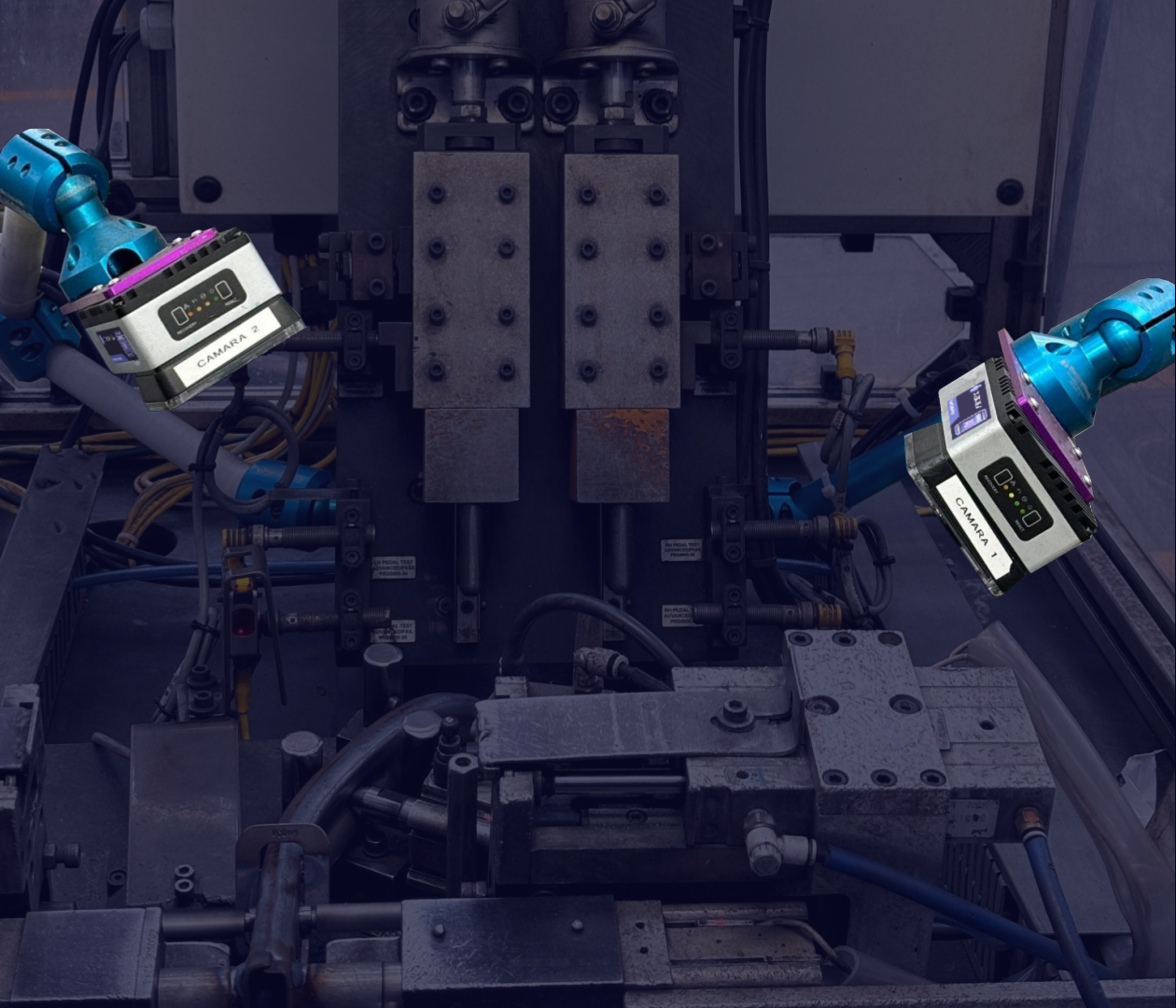

Overview AI runs all AI inference at the edge, on NVIDIA hardware inside our inspection systems:

Edge AI Benefits

- • Your images never leave your facility

- • Inspection happens in milliseconds, not seconds

- • No per-image cloud processing fees

- • No internet connectivity required for operation

- • Zero cloud dependency

Building Your GenAI Capabilities

Starting with Overview AI does more than solve an inspection problem. It builds organizational capabilities for the broader AI transformation ahead:

- Hands-On Experience: Your team learns AI concepts through practical application, not theory.

- Data Strategy: You develop practices for collecting, labeling, and managing training data.

- Model Lifecycle: Understanding training, validation, deployment, and retraining prepares you for other AI initiatives.

- Integration Patterns: Connecting AI outputs to PLCs, MES, and quality systems establishes patterns for future deployments.

Start with Proven Technology

Overview AI is not experimental technology. Our AI-powered inspection systems are deployed in production environments across automotive, pharmaceutical, electronics, and consumer goods manufacturing. The technology is proven. The path to deployment is clear.

Your GenAI journey in manufacturing should start where the technology is mature, the value is measurable, and the risk is minimal. That starting point is visual quality inspection with Overview AI. For a broader perspective on AI adoption, see our guide on how to start AI transformation in manufacturing.

Ready to Deploy GenAI in Your Factory?

See how Overview AI applies advanced AI to deliver production-ready quality inspection in hours, not months.

Schedule a Demo