Edge AI vs Cloud AI for Manufacturing: Which is Right for You?

When implementing AI in manufacturing, one of the first architectural decisions you'll face is where AI processing happens: at the edge (on-premise, close to the production line) or in the cloud (remote data centers). This choice impacts everything from latency and reliability to data security and total cost.

This article provides a comprehensive comparison to help you choose the right approach for your manufacturing AI applications.

Understanding the Architectures

Edge AI

Edge AI processes data locally, right at or near the production line. Cameras capture images that are immediately analyzed by AI running on dedicated computing hardware in the factory. Results are available in milliseconds without any data leaving the facility.

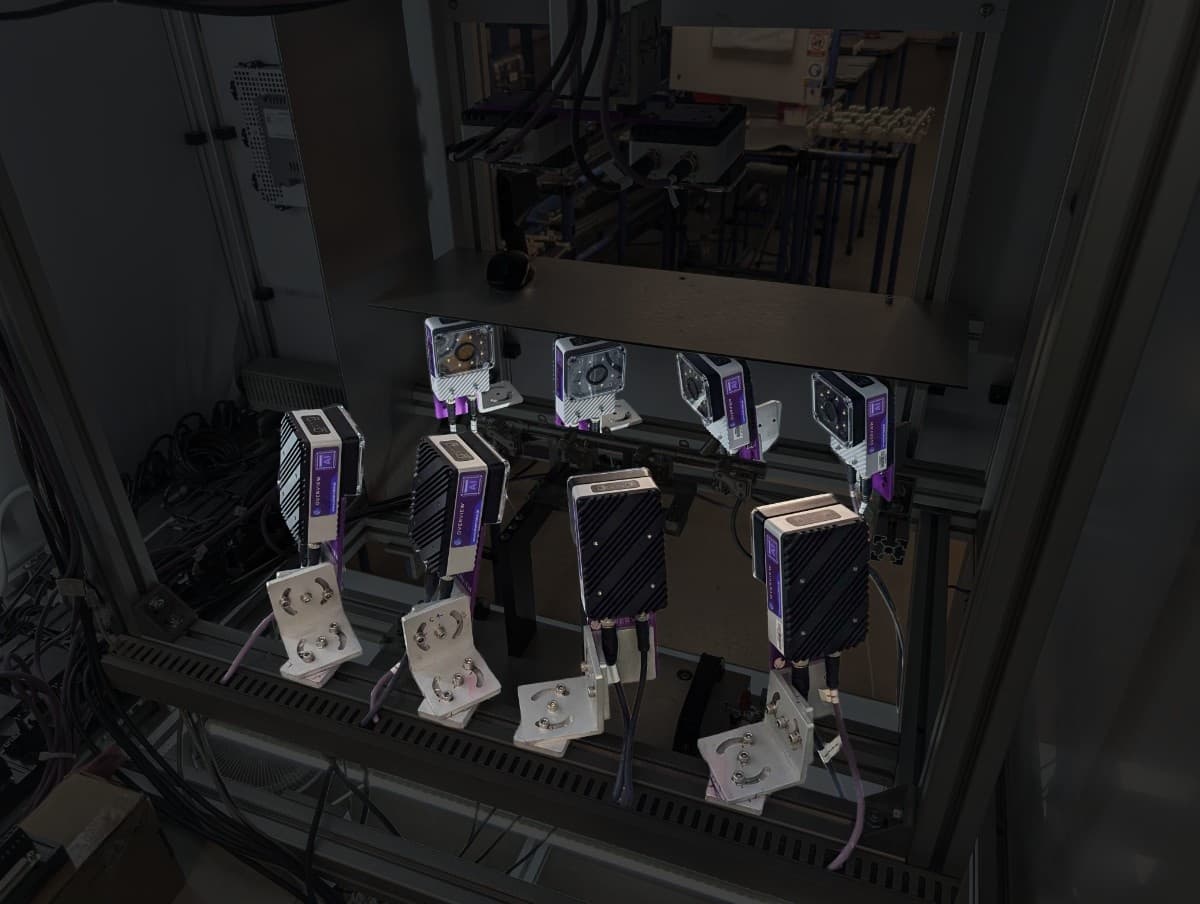

Modern edge AI platforms pack powerful GPU or specialized AI accelerators into industrial-hardened form factors. They can run sophisticated deep learning models locally, achieving the same accuracy as cloud-based processing.

Cloud AI

Cloud AI sends data from the factory to remote servers for processing. Images are uploaded over the network to cloud infrastructure where powerful servers run AI analysis. Results are then transmitted back to the factory.

Cloud platforms offer virtually unlimited computing capacity and access to the latest AI models. Major cloud providers offer vision AI services that can classify images, detect objects, and identify defects.

Key Comparison Factors

Latency

Latency (the time between image capture and result) is often the deciding factor for manufacturing applications.

Edge AI Latency

Typically 10-100 milliseconds

Processing happens locally with no network round-trip. Results are available almost instantly after image capture.

Cloud AI Latency

Typically 200-2000+ milliseconds

Network upload, cloud processing, and download all add delay. Latency varies with network conditions and cloud load.

For high-speed production lines, cloud latency is often prohibitive. If you're inspecting parts moving at 60 per minute (one per second), a 500ms round-trip to the cloud doesn't leave time for the AI to analyze images before the next part arrives. Edge AI handles high-speed inspection with ease.

Reliability

Production uptime is critical in manufacturing. Unplanned downtime costs money.

Reliability Comparison:

Edge AI

Operates independently of internet connectivity. The factory's internal network and power are the only dependencies. Industrial-grade hardware is designed for 24/7 operation in factory conditions.

Cloud AI

Depends on internet connectivity, cloud service availability, and intermediate network infrastructure. Any link in the chain failing stops inspection. ISP outages, cloud service incidents, and network issues all cause downtime.

For mission-critical inspection where stopping means stopping production, edge AI's independence from external dependencies is a significant advantage. Learn more about how AI vision systems work.

Data Security and Privacy

Manufacturing data, including product images, quality metrics, and process information, can be competitively sensitive. Where this data resides matters for security and compliance.

Edge AI: Data stays on-premise. Images are processed locally and never leave the facility unless you explicitly choose to export them. This simplifies data security and satisfies compliance requirements that restrict data from leaving controlled environments.

Cloud AI: Data must be transmitted to and stored in cloud infrastructure. While cloud providers implement strong security, data does leave your control. Regulatory requirements (ITAR, some customer contracts, regional data laws) may prohibit this.

Scalability

Both approaches scale, but in different ways:

Edge AI: Scales by adding edge devices. Each new inspection point gets its own processing. Costs are predictable, one device per inspection station. There's no economy of scale where one server handles multiple lines (each line needs dedicated hardware), but there's also no contention where high demand at one station impacts others.

Cloud AI: Scales elastically. Cloud resources expand automatically to handle load spikes. One cloud deployment can theoretically serve multiple facilities. However, bandwidth to the cloud becomes a bottleneck at scale; streaming high-resolution images from many cameras requires substantial network capacity.

Cost Structure

Cost models differ significantly between edge and cloud:

| Cost Category | Edge AI | Cloud AI |

|---|---|---|

| Upfront | Higher (hardware purchase) | Lower (no hardware) |

| Ongoing | Lower (no per-inference fees) | Higher (per-image or per-API-call) |

| Network | Minimal (local only) | Significant (bandwidth costs) |

| Predictability | Fixed, predictable | Variable with volume |

For high-volume inspection, edge AI is typically more economical. Cloud costs accumulate with every image processed, while edge costs are fixed once hardware is purchased. For lower volumes or intermittent use, cloud's pay-per-use model may be advantageous.

Model Management

AI models need updates as new defect types emerge or products change.

Edge AI: Models must be deployed to each edge device. This requires a deployment process but ensures you control exactly what's running. Changes happen when you choose to deploy them.

Cloud AI: Updates happen centrally. Once a new model is deployed to the cloud, all connected systems immediately use it. This can be an advantage (instant updates) or a risk (unintended behavior change affecting production).

Hybrid Approaches

Some applications benefit from combining edge and cloud:

- Edge inference, cloud training: Run real-time inspection at the edge, but send data to cloud for model training and improvement

- Edge primary, cloud backup: Process at edge normally, fail over to cloud if edge devices have issues

- Edge for real-time, cloud for batch: Immediate inspection at edge, deeper analytics in cloud

- Edge for sensitive data, cloud for general: Keep proprietary images local, use cloud for non-sensitive analysis

When to Choose Edge AI

Edge AI is typically the better choice when:

- • Real-time response is required (high-speed lines)

- • Reliability is critical (can't afford network-dependent downtime)

- • Data security requirements prohibit cloud transmission

- • Internet connectivity is limited or unreliable

- • Inspection volume is high (cost per image matters)

- • Deterministic, predictable behavior is required

When to Choose Cloud AI

Cloud AI may be appropriate when:

- • Latency requirements are relaxed (seconds are acceptable)

- • Inspection volume is low or intermittent

- • Multiple facilities need coordinated analysis

- • Minimizing upfront investment is a priority

- • Network connectivity is excellent and reliable

- • Data sensitivity is not a concern

The Manufacturing Reality

For most in-line quality inspection applications, edge AI is the appropriate choice. The combination of latency requirements, reliability needs, and data security concerns makes cloud processing impractical for real-time manufacturing use cases.

Cloud AI has a role in manufacturing for non-real-time applications: training models on historical data, aggregating quality analytics across plants, or analyzing images that have been collected for offline review. But for the actual inspection, making pass/fail decisions on products moving through production, edge AI is the industrial standard.

Modern edge AI platforms from companies like Overview.ai deliver industrial-grade reliability with powerful AI capabilities. Purpose-built for manufacturing environments, these systems combine high-performance edge computing with easy deployment and management, with no cloud dependency required.

Experience Edge AI Performance

See how edge AI delivers real-time inspection performance with industrial reliability in a personalized demonstration.

Request a Demo