How to Start AI Transformation in Manufacturing

Every manufacturing executive knows AI is reshaping the industry. The question is not whether to adopt it, but where to start.

With countless AI applications promising to revolutionize everything from supply chain to predictive maintenance, the decision can be paralyzing. Here is what we have learned from working with manufacturers across automotive, electronics, pharmaceutical, and consumer goods: visual quality inspection is the single best place to begin your AI transformation.

Why Most AI Projects Struggle

Many enterprise AI initiatives face significant hurdles. The reasons are often predictable:

- Scope creep: Projects expand beyond their original boundaries, becoming unmanageable.

- Data problems: The required data doesn't exist, is poor quality, or lives in incompatible systems.

- Integration complexity: Connecting AI to existing systems proves far more complex than anticipated.

- Unclear ROI: Benefits are diffuse and hard to measure, making it difficult to justify continued investment.

- Talent gaps: Organizations lack the data science expertise to build and maintain models.

These challenges can poison the well for future AI adoption, creating skepticism that prevents organizations from capturing AI's genuine benefits.

Why Visual Quality Inspection is Different

Visual quality inspection sidesteps nearly every common AI pitfall:

Bounded Scope

A single inspection station is a self-contained project. You're not trying to transform the entire operation, just one specific quality check.

Fresh Data

You generate new training data every time the line runs. No archaeological expeditions into legacy systems required.

Standalone Operation

Modern AI vision systems can operate independently with minimal integration. Add complexity only when it delivers value.

Clear ROI

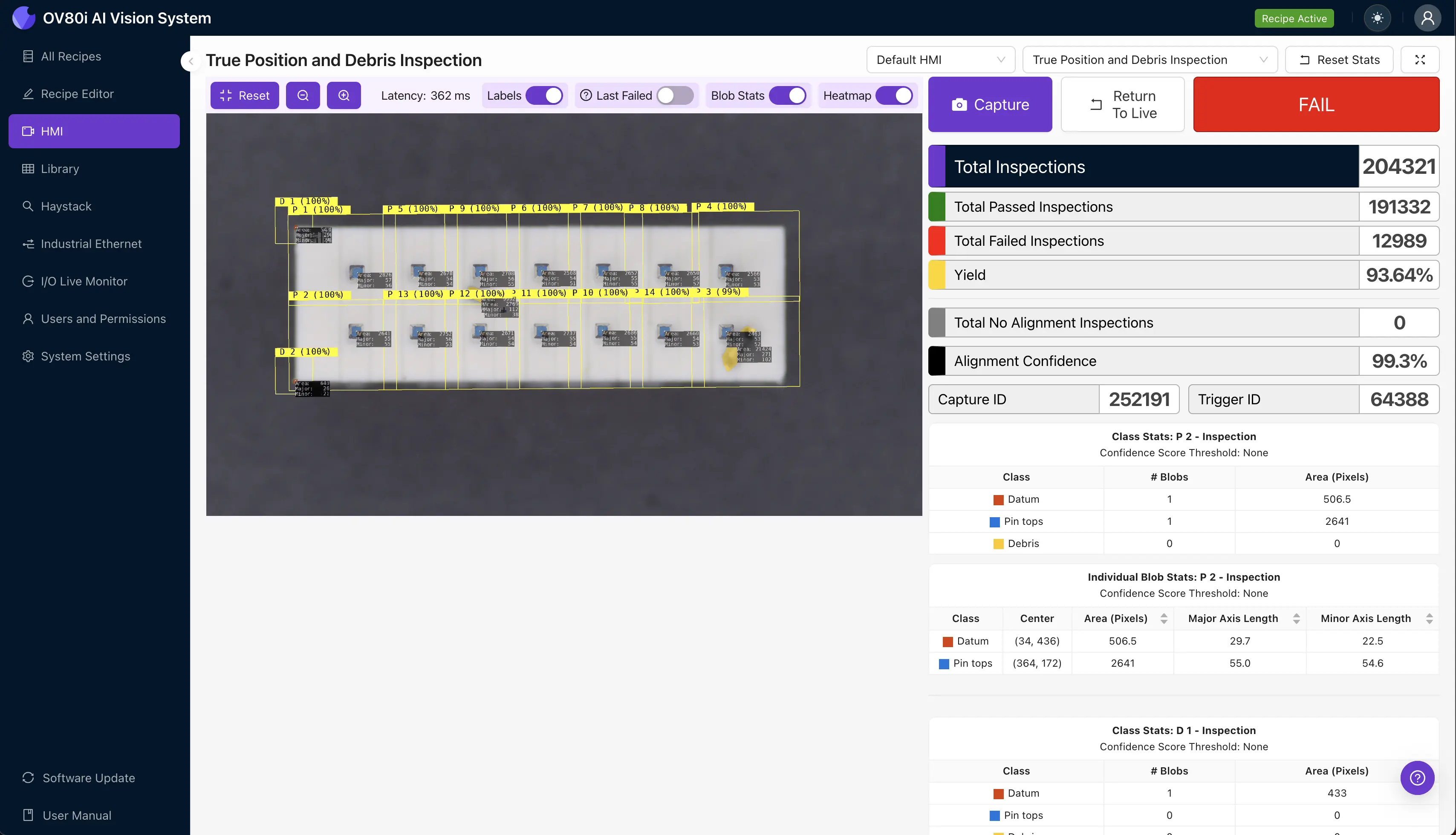

Defects caught vs. defects escaped. Labor hours saved. Scrap reduced. The math is straightforward.

What Makes Overview AI Different

Overview AI was built specifically to make your first AI project successful. Our approach differs from traditional machine vision by eliminating complexity and putting control in the hands of your existing team.

No Data Science Required

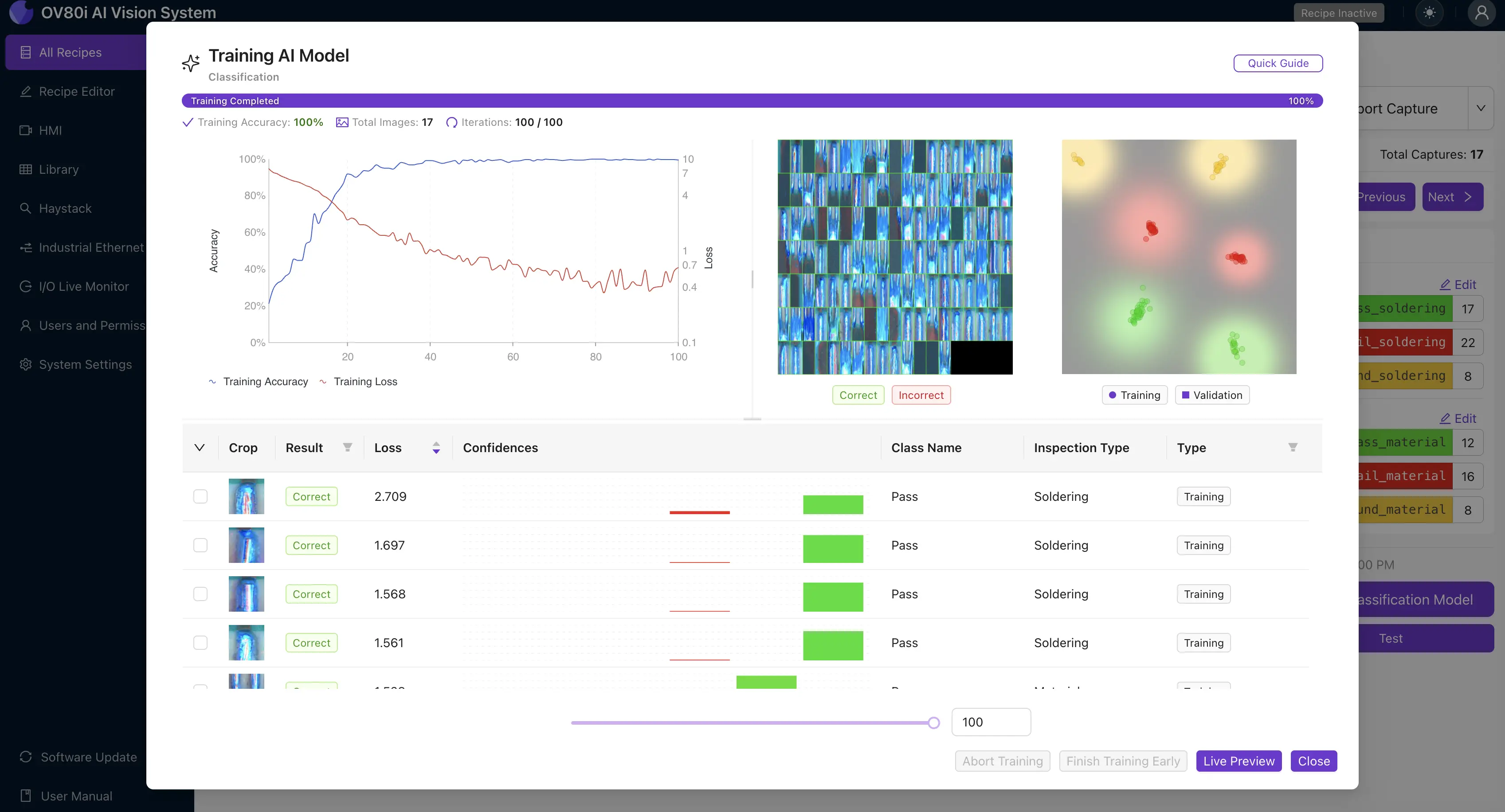

Traditional AI projects require teams of data scientists, ML engineers, and software developers. With Overview AI, your existing quality engineers can train and deploy models using our browser-based interface. No coding or complex programming required.

Deploy in Hours, Not Months

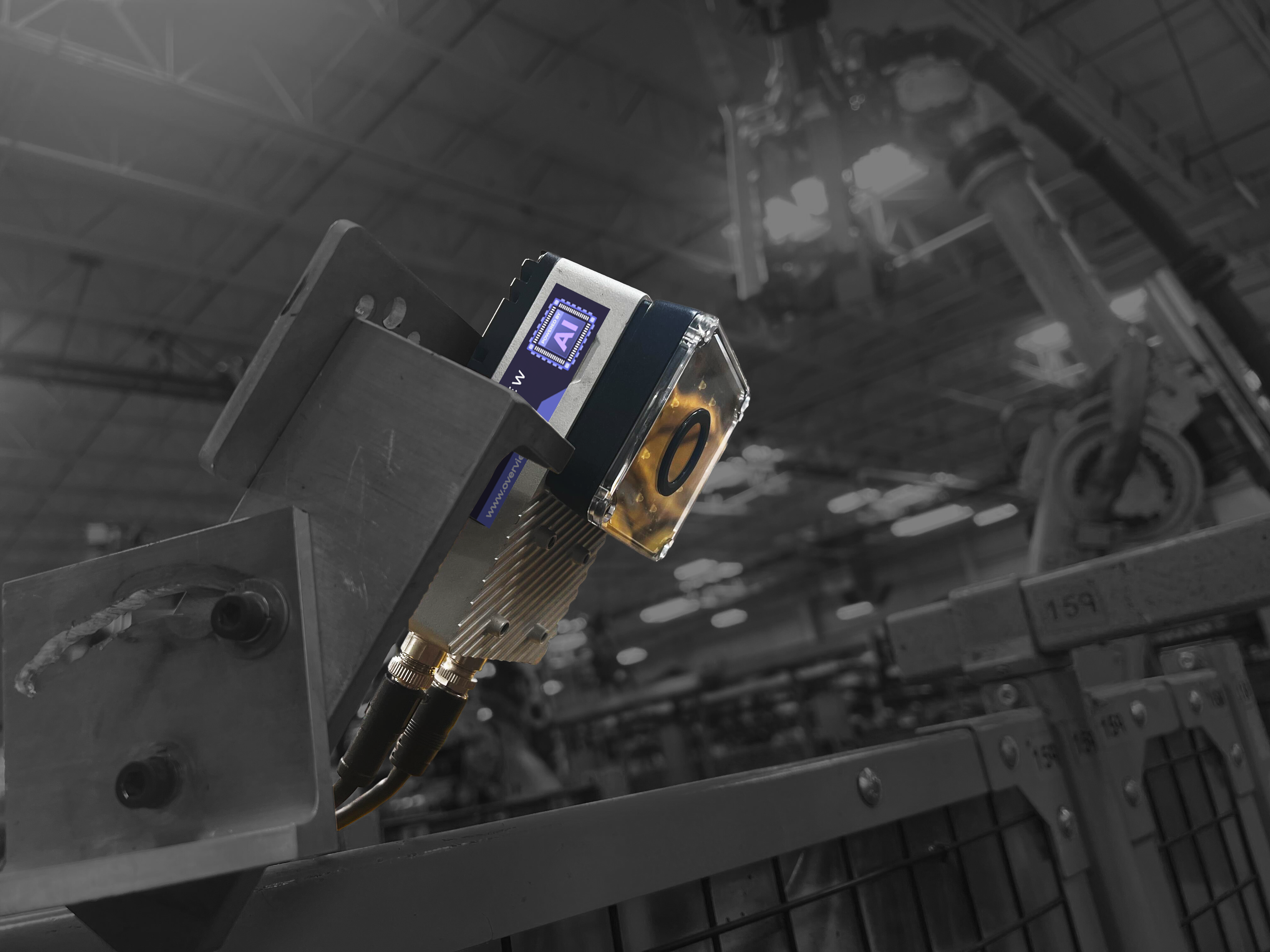

Our plug-and-play cameras come with pre-configured AI models that you can fine-tune in under an hour with as few as 5 example images. Traditional vision systems required extensive programming knowledge and weeks of setup time. Learn more about our fast implementation approach.

Typical Overview AI Timeline:

- Installation: Mount the camera and connect power (under 2 hours to full deployment)

- Data Collection: Capture images from production

- Model Training: Train your first model in under 1 hour with as few as 5 images

- Production: Begin inspection immediately

- Refinement: Fine-tune based on real-world performance

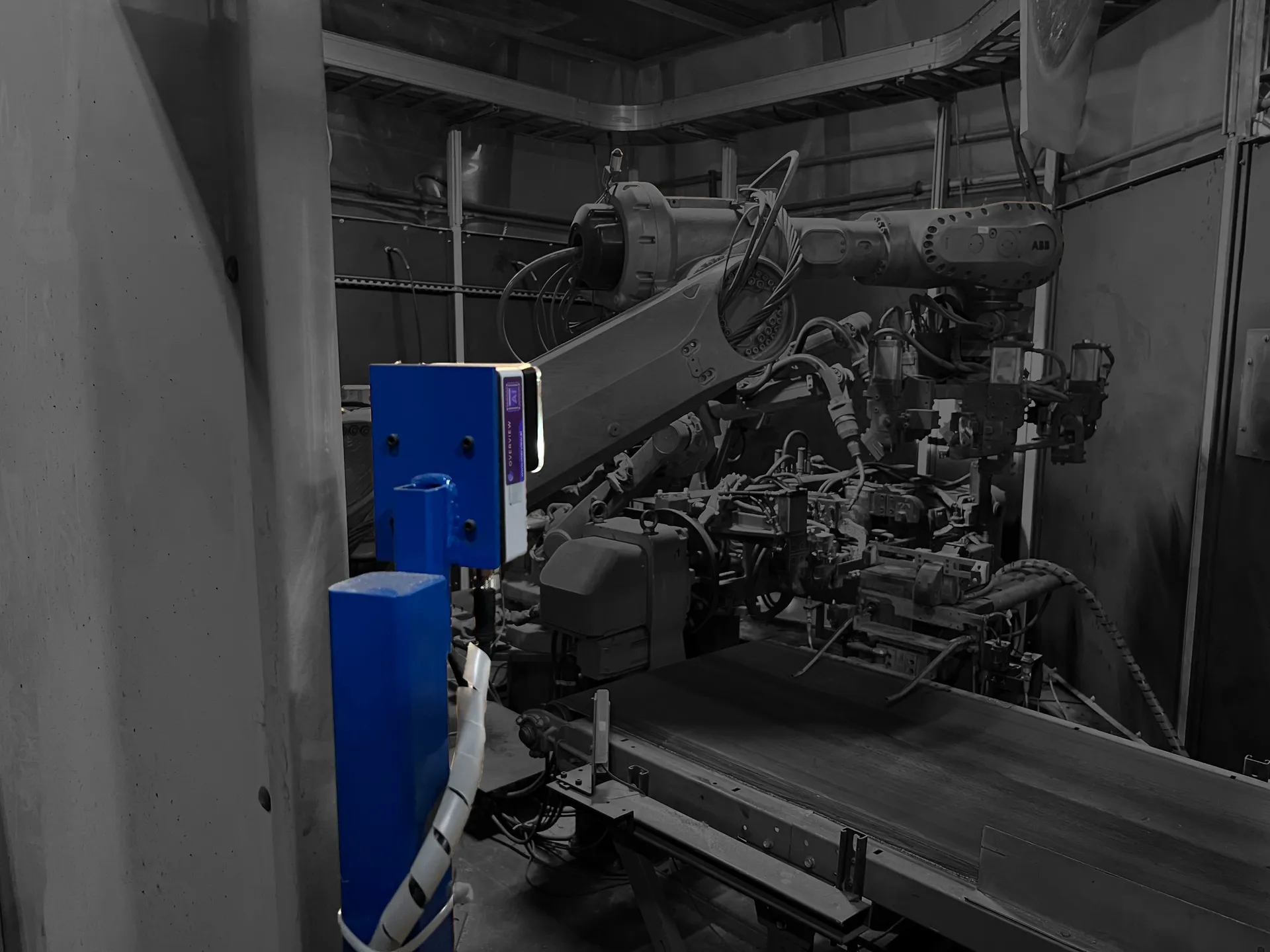

Complete System, Not Just Software

Many AI vendors sell software and leave you to figure out cameras, lighting, compute hardware, and integration. Overview AI delivers complete, pre-configured systems. Our OV20i and OV80i units include industrial cameras, optimized lighting, NVIDIA edge computing, and our AI software, all integrated and tested before shipping.

Edge AI Architecture

- • All processing on integrated NVIDIA GPU

- • No cloud required, no latency

- • Your data stays in your facility

- • No subscription fees for processing

Industrial Integration Ready

Overview AI cameras support standard industrial protocols including Ethernet/IP, Profinet, and Modbus TCP for direct PLC communication, as well as MQTT, OPC-UA, and HTTP for MES/SCADA integration. Trigger inspections via digital I/O, network commands, or software triggers.

Building Your AI Capabilities

Starting with visual quality inspection does more than solve an immediate problem. It builds organizational capabilities that accelerate future AI adoption:

- AI Literacy: Your team gains hands-on experience with AI model training, deployment, and monitoring.

- Change Management: You develop processes for introducing AI to the shop floor.

- Success Stories: Concrete results build organizational appetite for further AI investment.

- Data Foundation: Inspection data becomes a valuable asset for future analytics and process improvement.

What Manufacturers Experience with Overview AI

Manufacturers across automotive, electronics, medical devices, and consumer goods have chosen Overview AI as their entry point to AI-powered quality control. They report:

- Reduced escaped defects: Catching more issues before shipment reduces customer complaints, returns, and warranty costs.

- Lower scrap costs: Earlier detection means less value added to defective parts before rejection.

- Labor efficiency: Automated inspection reduces dependency on manual inspection staff.

- Process insights: Inspection data reveals root causes of quality issues.

- Faster throughput: Removing the inspection bottleneck increases line output.

Getting Started is Easier Than You Think

Overview AI has streamlined every aspect of getting started:

- Application Assessment: Our engineers review your inspection challenge and confirm fit.

- Proof of Concept: Test with your actual parts before committing.

- Turnkey Delivery: Receive complete, configured systems ready to deploy.

- Expert Training: On-site training ensures your team is confident from day one.

- Ongoing Support: Our support team is available when you need help.

AI transformation does not have to mean a multi-year initiative with uncertain outcomes. It can start with a single inspection station, proven technology, and results in days instead of years. For more on how generative AI specifically applies to manufacturing, see our guide on how to use GenAI in manufacturing.

Overview AI is where manufacturing's AI transformation begins.

Ready to Start Your AI Transformation?

See why leading manufacturers choose Overview AI as their first step into AI-powered quality inspection.

Schedule a Demo